Method for preparing high-purity anhydrous strontium iodide

A strontium iodide, high-purity technology, applied in the direction of calcium/strontium/barium halide, etc., can solve the problems of high preparation cost, difficult condition control, environmental pollution, etc., and achieve the effects of simple operation, little environmental pollution, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

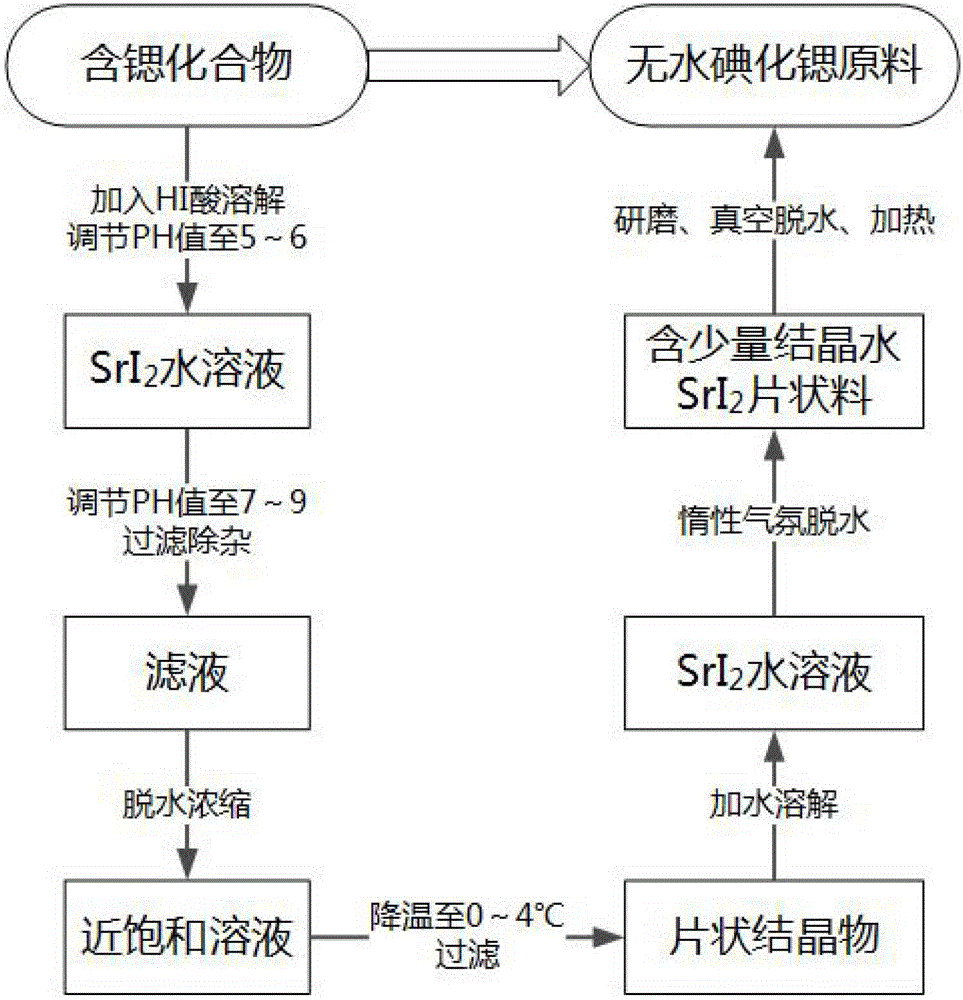

[0030] The invention provides a preparation method of high-purity strontium iodide. The preparation method mainly includes: a reaction step of reacting a strontium-containing compound with hydroiodic acid to generate strontium iodide; a purification step of purifying the generated strontium iodide to obtain a flaky hydrous crystal; removing the hydrous crystal in an inert atmosphere. Most of the water of crystallization, obtain the first water removal step of strontium iodide containing a small amount of water of crystallization; and remove the remaining small amount of water of crystallization under vacuum conditions to obtain the second water removal step of anhydrous strontium iodide.

[0031] figure 1 A specific process flow diagram of an example of the present invention is shown. Such as figure 1 As shown, the preparation method of the present invention may specifically include the following steps.

[0032] (1) Add a certain amount of deionized water into the reaction ...

Embodiment 1

[0041] (1) Add 5.4 grams of deionized water to a 250ml glass beaker and weigh strontium carbonate (SrCO 3 ) Put 7.38 grams of raw materials in a reaction vessel, add hydroiodic acid with a purity of not less than 99.9% dropwise, and stir with a magnetic stirrer to completely react strontium carbonate and hydroiodic acid until the solution is clear and the pH value is 5.5 , stop adding hydroiodic acid;

[0042] (2) Adjust the pH value of the solution to 7.5 by adding a small amount of ammonia water, and filter to remove impurities; stir and heat the obtained strontium iodide aqueous solution at 100°C±2°C until the solution is concentrated to 2 / 5 of the initial capacity , stop heating and immediately put the glass beaker into ice cubes, so that the temperature of the solution in the beaker is rapidly reduced to 2-3 ° C, and a large number of flaky crystals are precipitated in the solution;

[0043] (3) The crystals were separated from the mother liquor by vacuum filtration to o...

Embodiment 2

[0049] (1) Add 54 grams of deionized water into a 1000ml glass beaker, weigh 51.81 grams of strontium oxide raw material with a purity of 99.99%, place it in a reaction vessel, and add hydroiodic acid with a purity higher than 99.9% dropwise for neutralization reaction , stirring by a magnetic stirrer makes the reaction complete, and stops adding hydroiodic acid when the pH value of the solution is 5.0;

[0050] (2) Adjust the pH value of the solution to 7.0 by adding a small amount of ammonia water, and filter to remove impurities; put the obtained strontium iodide aqueous solution into a quartz crucible, and use a water ring vacuum pump to evacuate the quartz crucible for 2 hours, so that The aqueous solution of strontium iodide is concentrated, and the quartz crucible containing the concentrated solution is immediately placed in ice cubes, so that the temperature of the concentrated solution is rapidly reduced to 1-2°C, and a large number of flaky crystals are precipitated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com