Magnetism recovery device for magnetization of feebly magnetic ore by roasting on two pallets

A weak magnetic, double trolley technology, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of high magnetization cost, limited single furnace production capacity, complicated process, etc., and achieve uniform production quality and social benefits. Considerable and short infrastructure cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

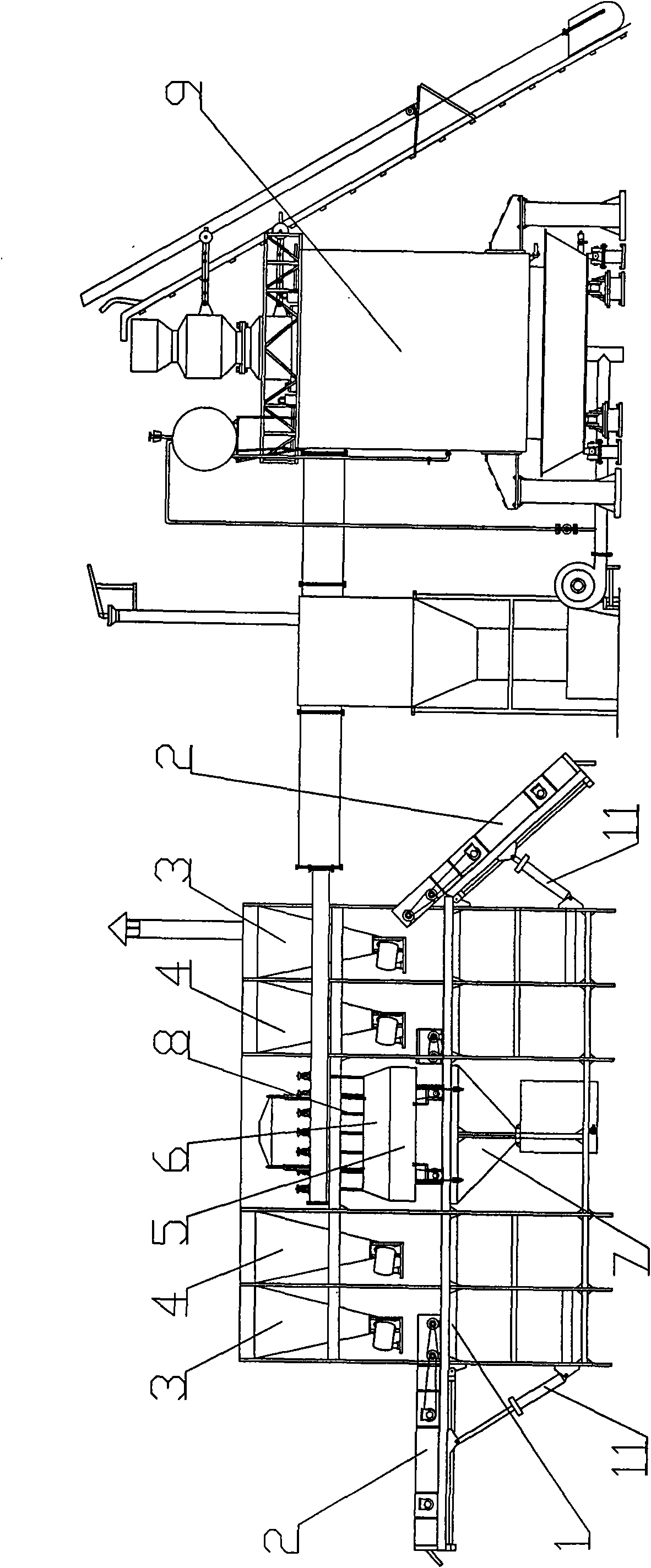

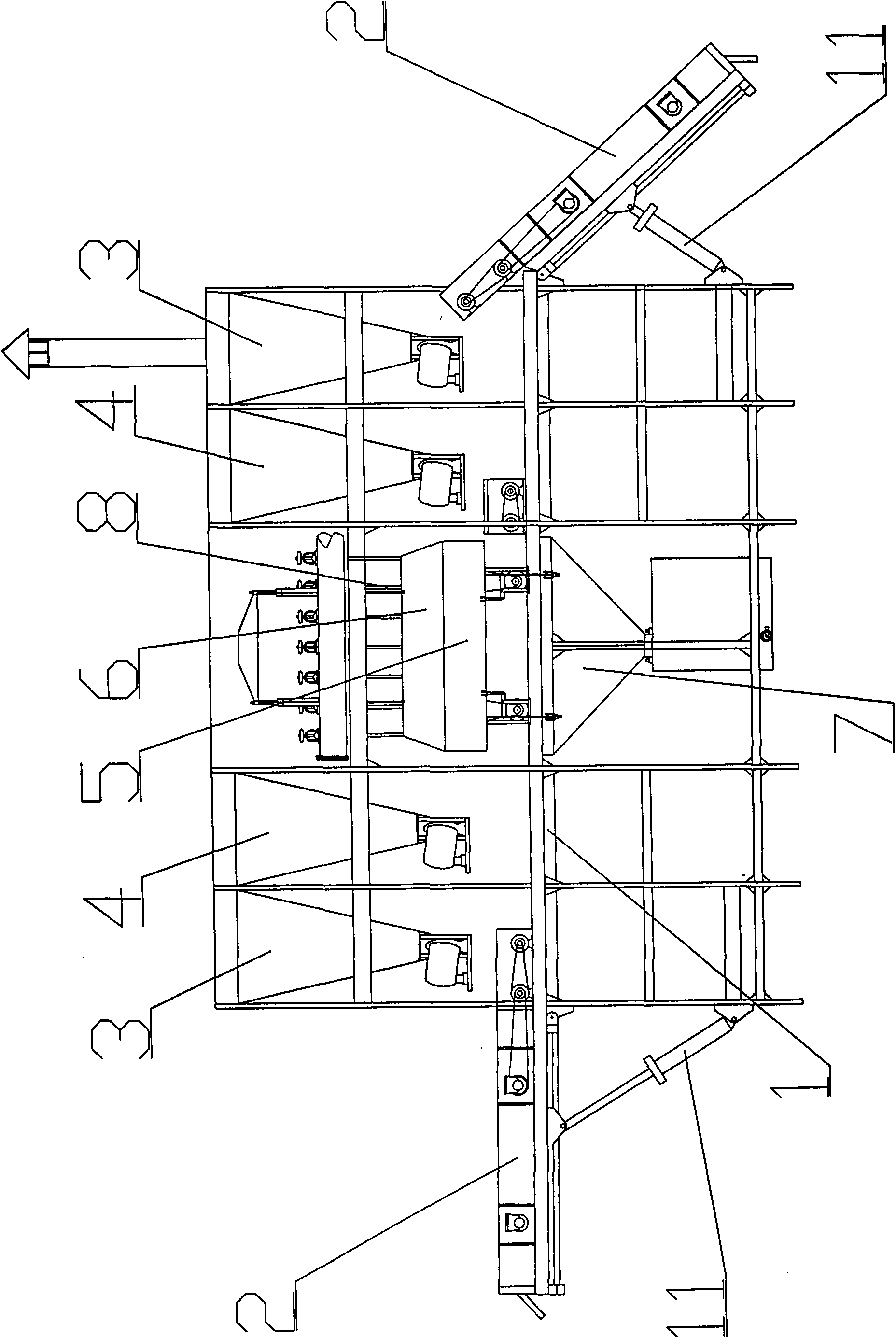

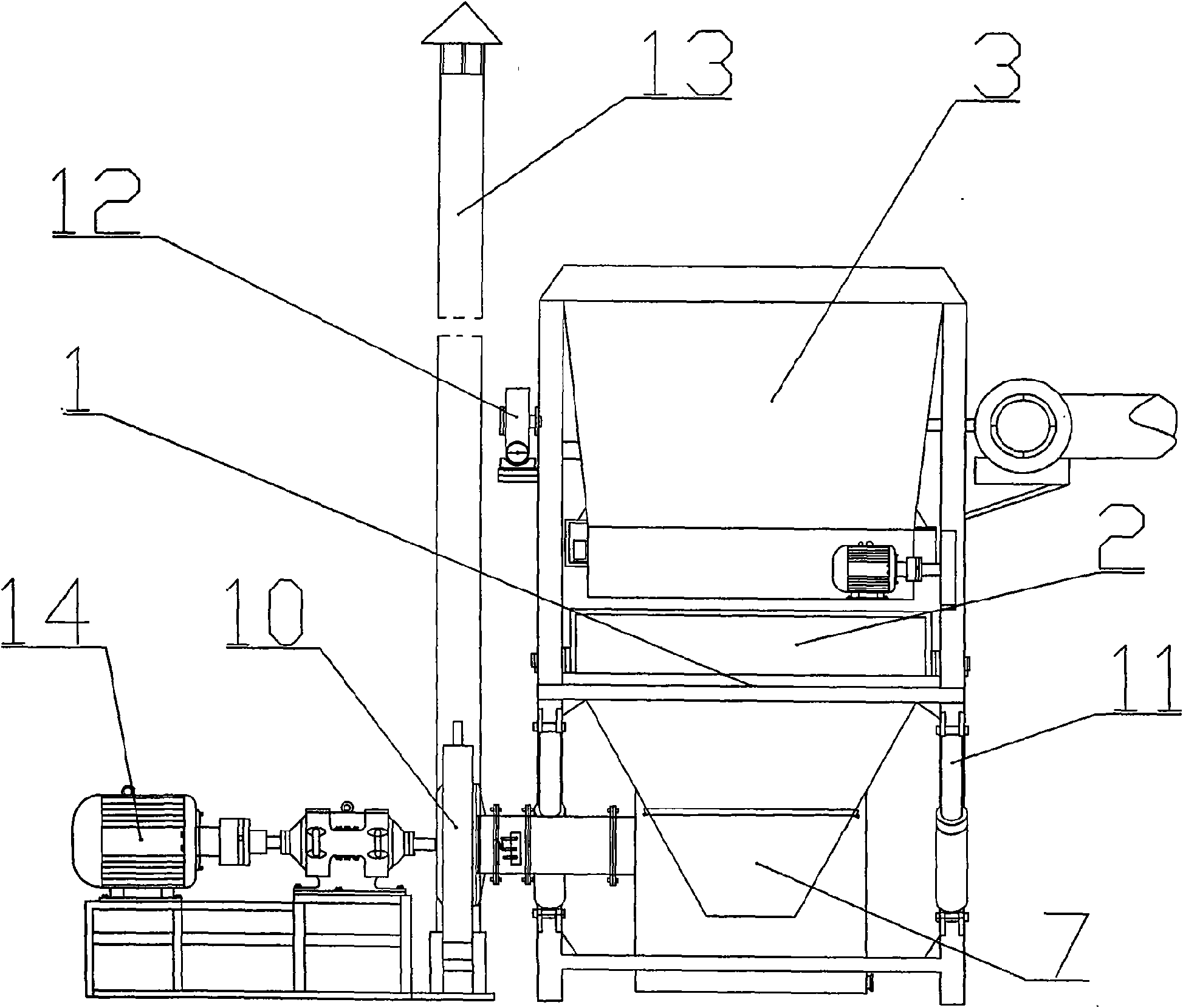

[0034] Referring to the accompanying drawings, the double trolley roasting magnetization weak magnetic ore magnetic return equipment of the present invention comprises a gas generating mechanism, a charging mechanism, a discharging mechanism, a frame and a hydraulic control mechanism, and two ends are symmetrically arranged on the frame 1. A trolley 2 is provided with a track on the frame, and the trolley 2 moves on the track; wherein the charging mechanism has two sets, which are matched to the top of the trolley 2, and each set of charging mechanism includes a side-by-side Two hoppers 3, 4 and an ore conveying device; the gas generating mechanism is connected with the combustion mechanism; the gas generating mechanism is composed of a gas generator 9; the combustion mechanism is arranged in the middle of two trolleys, which includes Roasting chamber 5, described roasting chamber 5 is made up of upper and lower wind cover 6,7 and moving trolley 2, is provided with gas nozzle 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com