Magnetism recovery device for magnetization of feebly magnetic ore by roasting on two pallets

A technology with weak magnetism and double trolleys, which is applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of single furnace production capacity limitation, high magnetization cost, and difficulty in uniform heating, and achieve considerable social benefits and production Uniform quality and highly operable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

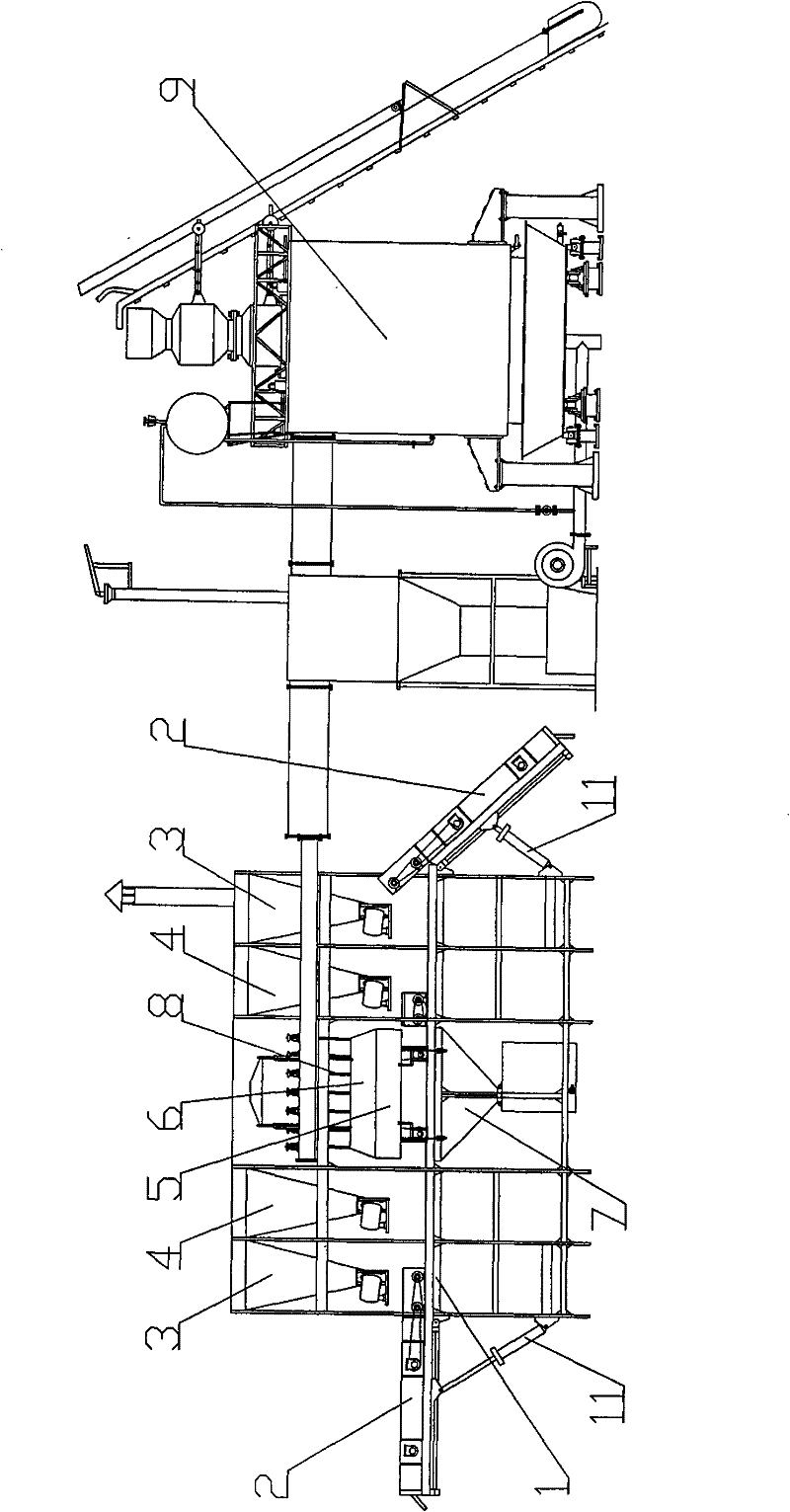

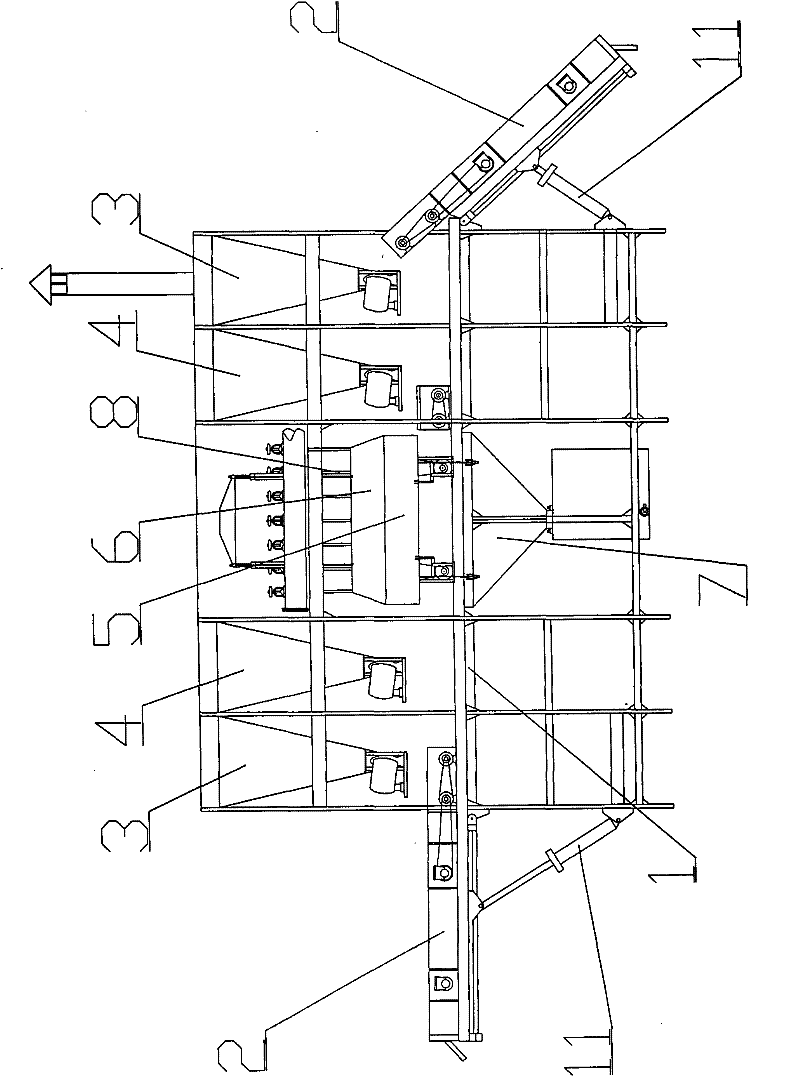

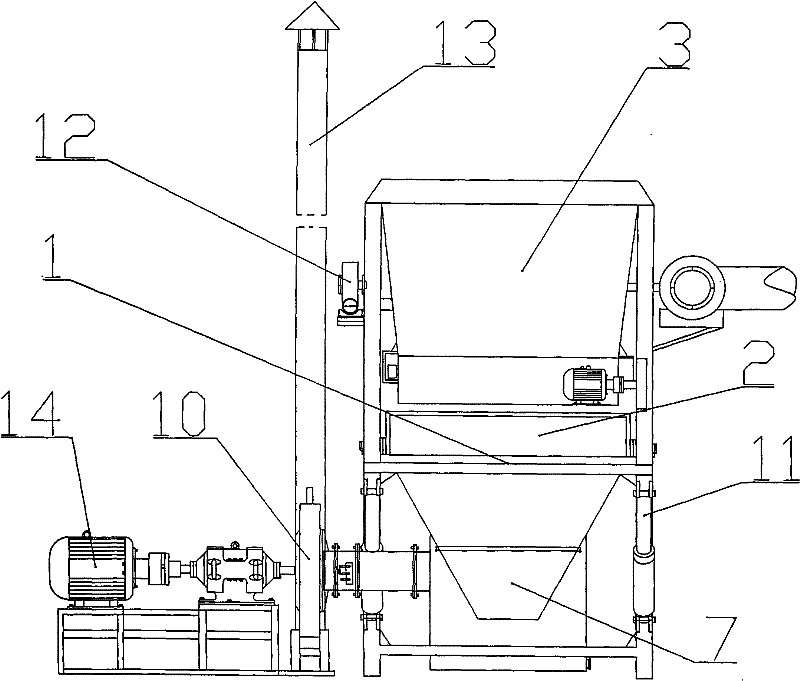

[0034] With reference to the drawings, the double trolley roasting magnetized weakly magnetic ore and magnetizing equipment of the present invention includes a gas generating mechanism, a charging mechanism, a discharging mechanism, a frame and a hydraulic control mechanism, and two symmetrical two ends are arranged on the frame 1. The trolley 2 is equipped with a track on the frame, and the trolley 2 moves on the track; wherein there are two sets of the loading mechanism, which are provided on the top of the trolley 2, and each set of the material mechanism includes a parallel arrangement Two hoppers 3, 4 and an ore conveying device; the gas generating mechanism is connected with the burning mechanism; the gas generating mechanism is composed of a gas generating furnace 9; the burning mechanism is set in the middle of the two vehicles, which includes The roasting chamber 5, the roasting chamber 5 is composed of upper and lower air hoods 6, 7 and a movable trolley 2, and a gas n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com