Method for preparing block copolymer hollow fiber membrane based on selective swelling method

A technology of block copolymers and copolymers, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as difficult to scale up production, limitations, and poor mechanical properties of hollow fiber membranes, so as to avoid environmental pollution and improve production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 20g PSF 75 -PEG 20 The block copolymer is fed into a twin-screw extruder, melted at 170 / 180°C, then extruded through a spinneret with a size of 0.5 / 0.28 / 0.15mm at 170°C, and naturally cooled to obtain a hollow fiber. The obtained hollow fiber was immersed in a mixed solvent of n-propanol and acetone containing 20wt% acetone, and treated in a water bath at 65° C. for 1 h. Immediately after the treatment, the hollow fiber was taken out and dried at 40° C. to obtain a hollow fiber membrane.

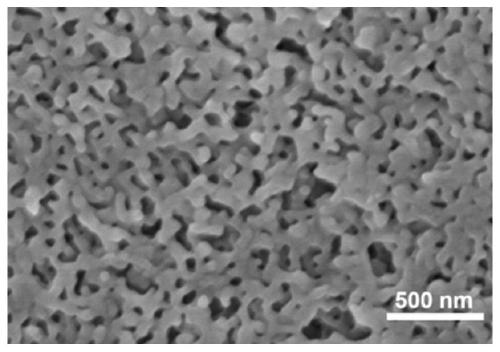

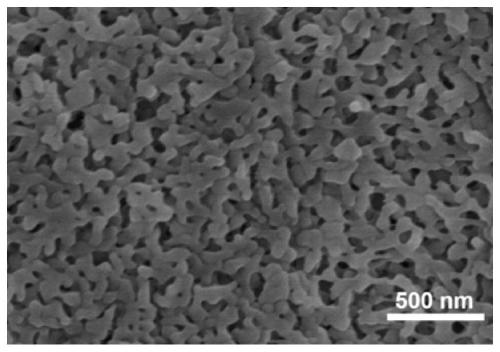

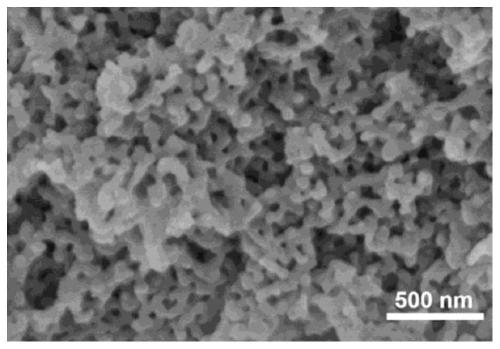

[0043] figure 1 , figure 2 , image 3 The SEM images of the inner and outer surfaces and cross-section of the polysulfone / polyethylene glycol hollow fiber membrane are respectively. It can be seen from the figure that the inner and outer surfaces of the hollow fiber membrane have a good open-pore structure, and the pore structure runs through the entire membrane layer. The prepared polysulfone / polyethylene glycol hollow fiber membrane has a pure water flux of 65L m- 2 h -1 · b...

Embodiment 2

[0045] 20g PSF 75 -PEG 20 The block copolymer is fed into a twin-screw extruder, melted at 170 / 180°C, then extruded through a spinneret with a size of 0.8 / 0.4 / 0.2mm at 170°C, and naturally cooled to obtain a hollow fiber. The obtained hollow fiber was immersed in a mixed solvent of n-propanol and acetone containing 20wt% acetone, and treated in a water bath at 65° C. for 1 h. Immediately after the treatment, the hollow fiber was taken out and dried at 40° C. to obtain a hollow fiber membrane.

[0046] The prepared polysulfone / polyethylene glycol hollow fiber membrane has a pure water flux of 50L m- 2 h -1 · bar -1 About, bovine serum albumin cut-off rate is about 24%.

Embodiment 3

[0048] 20g PSF 75 -PEG 20 The block copolymer is fed into a twin-screw extruder, melted at 170 / 180°C, then extruded through a spinneret with a size of 1.4 / 0.9 / 0.6mm at 170°C, and naturally cooled to obtain a hollow fiber. The obtained hollow fiber was immersed in a mixed solvent of n-propanol and acetone containing 20wt% acetone, and treated in a water bath at 65° C. for 1 h. Immediately after the treatment, the hollow fiber was taken out and dried at 40° C. to obtain a hollow fiber membrane.

[0049] The prepared polysulfone / polyethylene glycol hollow fiber membrane has a pure water flux of 40L m- 2 h -1 · bar -1 About, bovine serum albumin cut-off rate is about 21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com