One-way valve

A one-way valve and one-way valve technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of high cost, complex production process, complex structure, etc., and achieve simple processing, convenient use and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

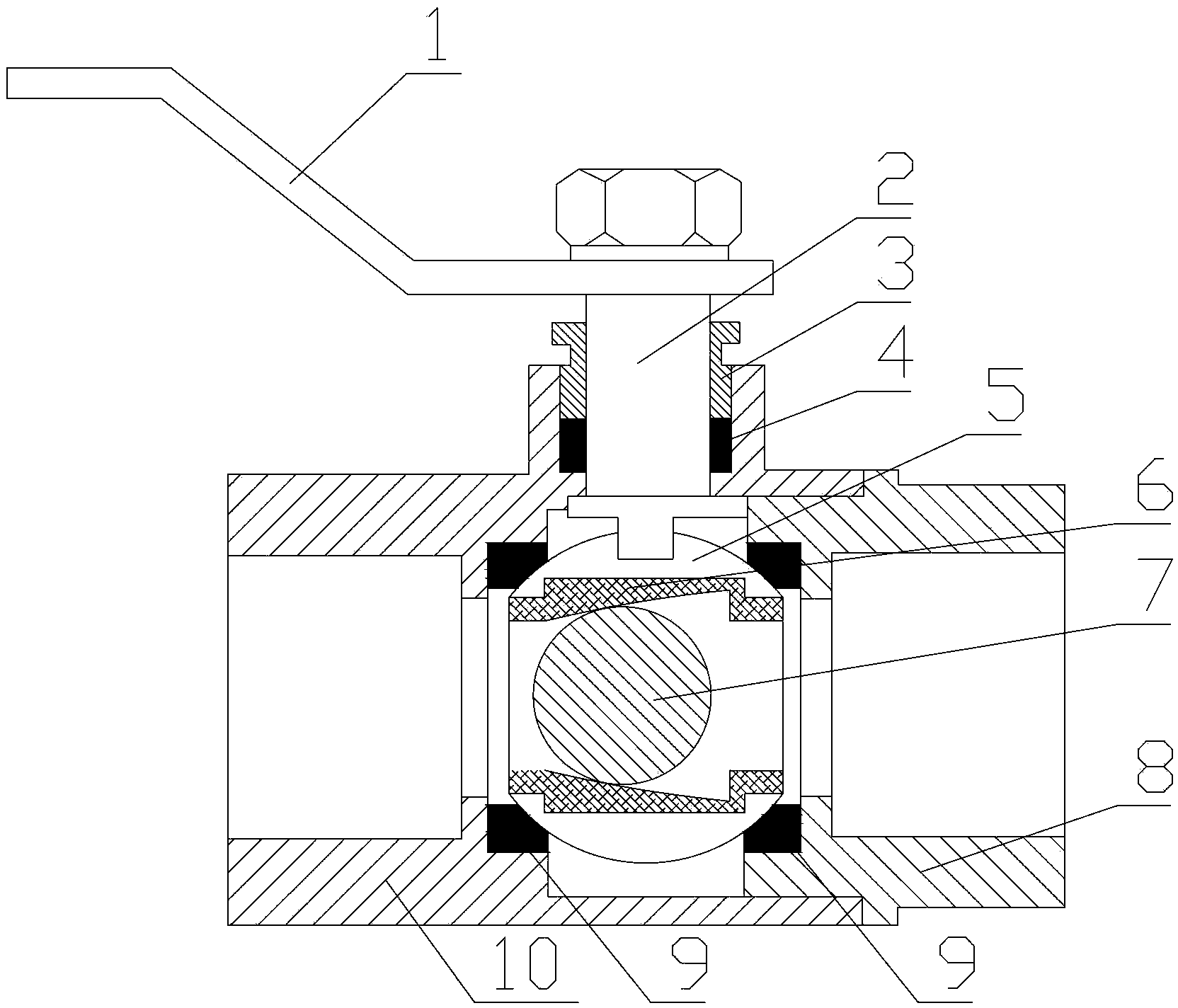

[0014] A specific embodiment of the present invention is shown in the accompanying drawings, the one-way valve is composed of a handle 1, a valve stem 2, an adjusting nut 3, a valve stem sealing ring 4, a valve core 5, an inlet valve body 8, a valve core sealing ring 9 and an outlet It consists of a valve body 10, the inlet valve body 8 is connected with the outlet valve body 10 through threads, and the valve core sealing ring 9 and the valve core 5 are encapsulated therein; the valve core 5 is connected with the valve stem 2, and the valve stem 2 is equipped with Handle 1; a valve stem sealing ring 4 is installed between the valve stem 2 and the outlet valve body 10, and is fixed by the adjusting nut 3; it is characterized in that: the valve core 5 is an inlet valve body 8 valve core installed in the outlet valve body 10 5 is connected with the valve stem 2; it is characterized in that the valve core 5 is a one-way valve core.

[0015] A through hole is processed in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com