PID (proportion, integral, derivative)-type?fuzzy logic control method based on weight rule table

A technology of fuzzy logic and control method, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of reducing the accuracy of fuzzy rule table, restricting the popularization and application of PID-type fuzzy logic control method, and difficulty in balancing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

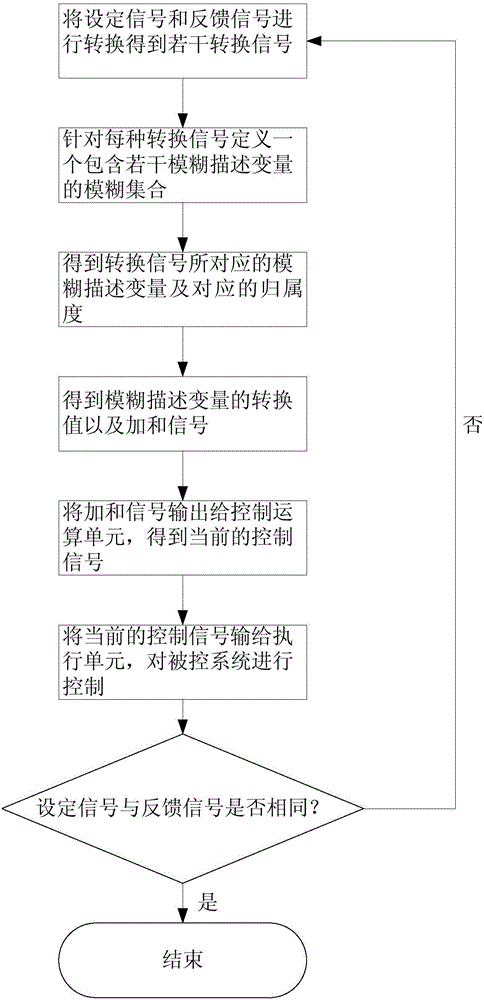

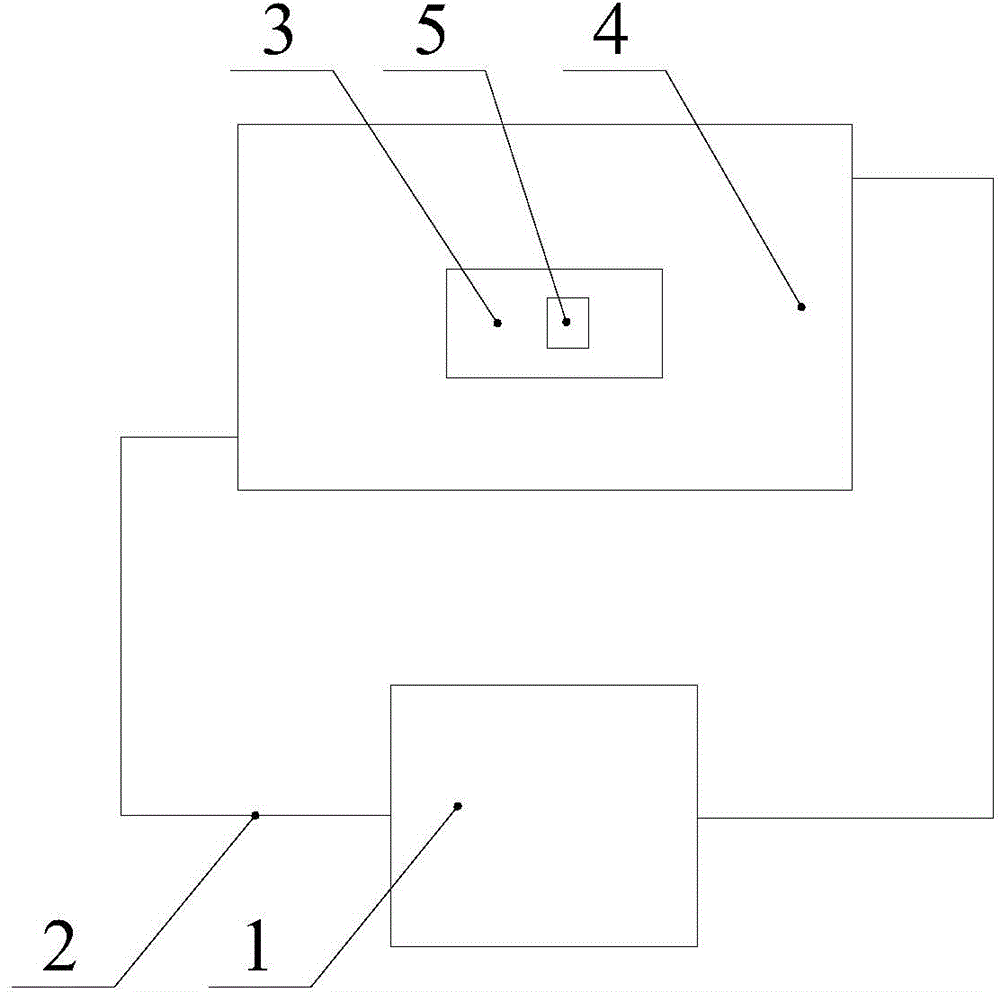

[0091] Such as figure 1 As shown, a PID type fuzzy logic control method based on the weight rule table includes the following steps:

[0092] 1) Convert the setting signal and feedback signal through the PID signal conversion unit to obtain several conversion signals.

[0093] Among them, the setting signal is r(t), the feedback signal is y(t), the conversion signal obtained by inputting the setting signal r(t) and the feedback signal y(t) into the PID signal conversion unit is the differential signal e(t), At least one of the three types of integral signal i(t) and differential signal d(t), where differential signal e(t)=y(t)-r(t), integral signal i(t)=∑e(t )*ts, differential signal d(t)=[e(t)-e(t-1)] / ts, ts is the sampling time unit.

[0094] 2) Define a fuzzy set containing several fuzzy description variables for each conversion signal, each fuzzy set has a corresponding belonging function, and define a corresponding weight value for each fuzzy description variable.

[0...

Embodiment 2

[0108] A PID type fuzzy logic control method based on a weight rule table of an air-conditioning system is characterized in that, comprising the following steps:

[0109] 1) Convert the room temperature setting signal and room temperature feedback signal through the PID signal conversion unit to obtain several conversion signals;

[0110] Among them, the room temperature setting signal is r(t), the room temperature feedback signal is y(t), the room temperature setting signal r(t) and the room temperature feedback signal y(t) are input into the conversion signal obtained by the PID signal conversion unit There are two kinds of differential signal e(t) and differential signal d(t), where differential signal e(t)=y(t)-r(t), differential signal d(t)=[e(t)-e( t-1)] / ts, ts is the sampling time unit.

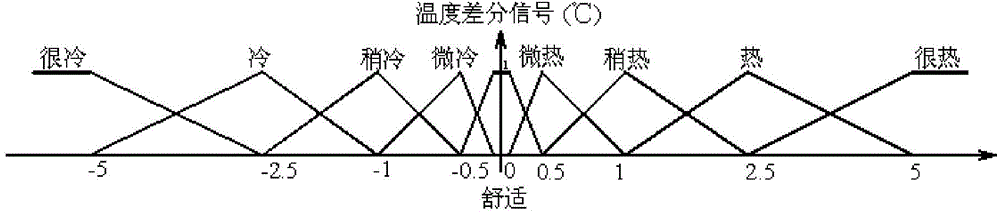

[0111] 2) Define a fuzzy set containing several fuzzy description variables for each conversion signal, each fuzzy set has a corresponding belonging function defined, and define a cor...

Embodiment 3

[0163] A PID type fuzzy logic control method based on a weight rule table of a central chilled water air conditioner comprises the following steps:

[0164] 1) Convert the water supply pressure setting signal of the water loop and the water supply pressure feedback signal of the water loop through the PID signal conversion unit to obtain several conversion signals.

[0165] Among them, the water supply pressure setting signal is r(t), the water supply pressure feedback signal is y(t), and the water supply pressure setting signal r(t) and the water supply pressure feedback signal y(t) are converted signals obtained by inputting the PID signal conversion unit It is at least one of the three types of differential signal e(t), integral signal i(t) and differential signal d(t), where differential signal e(t)=y(t)-r(t), and integral signal i(t)=∑e(t)*ts, differential signal d(t)=[e(t)-e(t-1)] / ts, ts is the sampling time unit.

[0166] 2) Define a fuzzy set containing several fuzzy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com