H-shaped steel worm and worm gear linkage clamping device

A worm gear and clamping device technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complicated operation process, large space occupation ratio, and large device volume, etc., and achieves simple and scientific structure. The effect of improving production efficiency, ensuring clamping accuracy and machining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

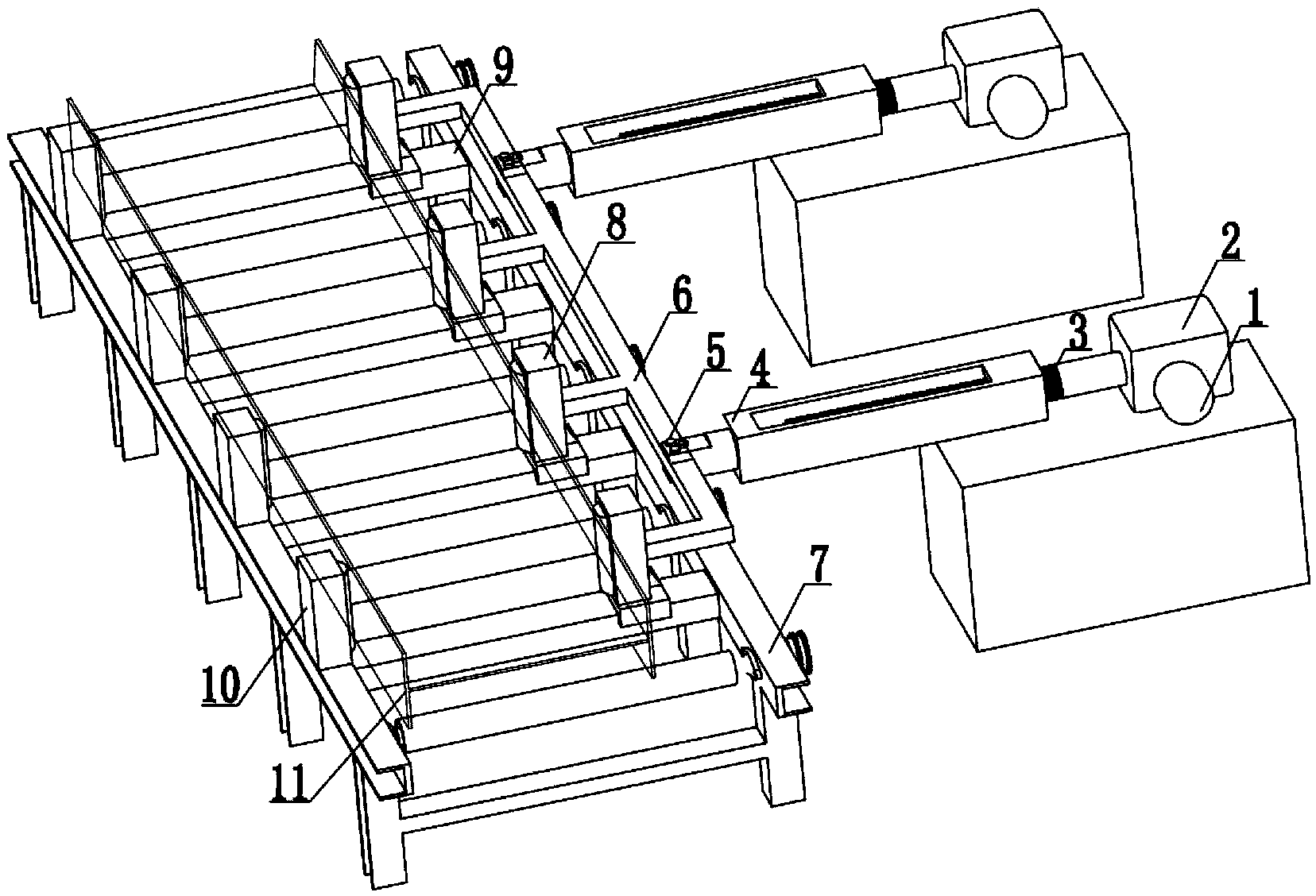

[0012] The present invention consists of a power drive device, a roller frame, and a clamping device. The clamping device is composed of a fixed clamping roller shaft and a movable clamping roller mechanism. The fixed clamping roller 10 corresponds to the distance between the rollers of the roller frame 7. The vacancy is fixedly installed on one side of the roller table frame 7; a slide rail 9 is provided in the space between the roller table of the roller table frame 7, and the linkage clamping roller shaft is connected by the roller shaft 8 and the connecting rod 6, and the linkage clamping roller shaft The roller shafts 8 and the slide rails 9 are slidably embedded in one-to-one correspondence, and are arranged on the other side of the roller frame relative to the fixed clamping roller shaft 10; the power drive device is composed of a motor 1, a worm gear reducer 2, a screw 3. The internal thread sleeve 4 is composed of two sets of power driving devices symmetrically arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com