High-modulus asphalt and preparation method thereof

A high-modulus, asphalt technology, used in building components, building insulation materials, buildings, etc., can solve the problem of no production method for high-modulus asphalt, high dynamic shear modulus at 64°C, and high storage modulus of asphalt mixtures. It can solve the problem of high temperature rutting and insufficient bearing capacity, high dynamic modulus and low modification cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

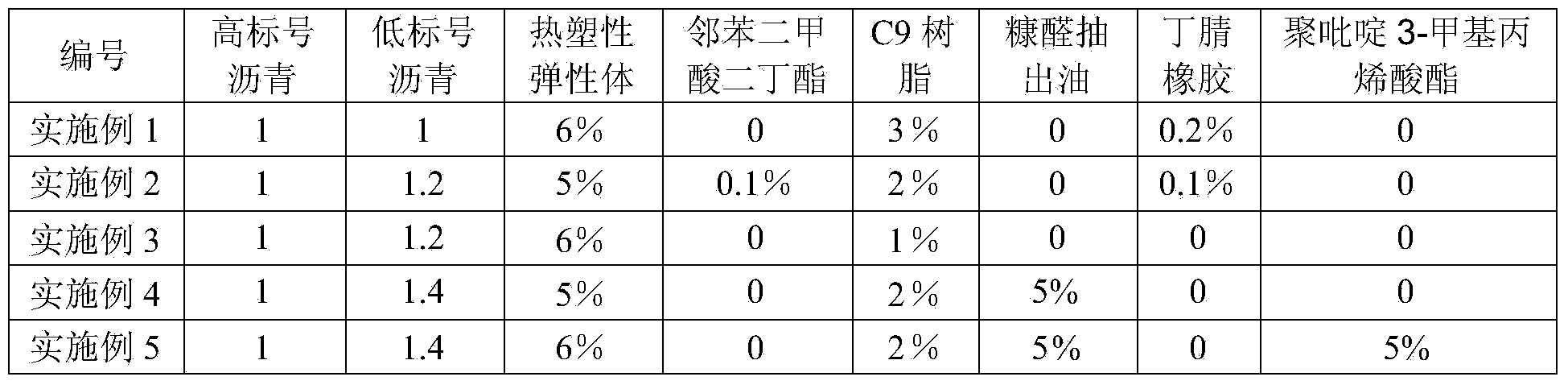

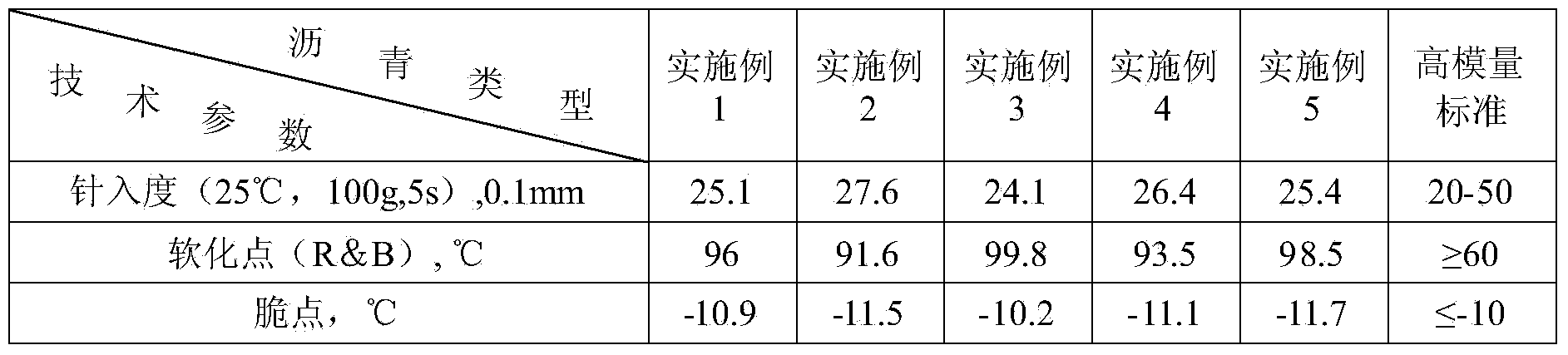

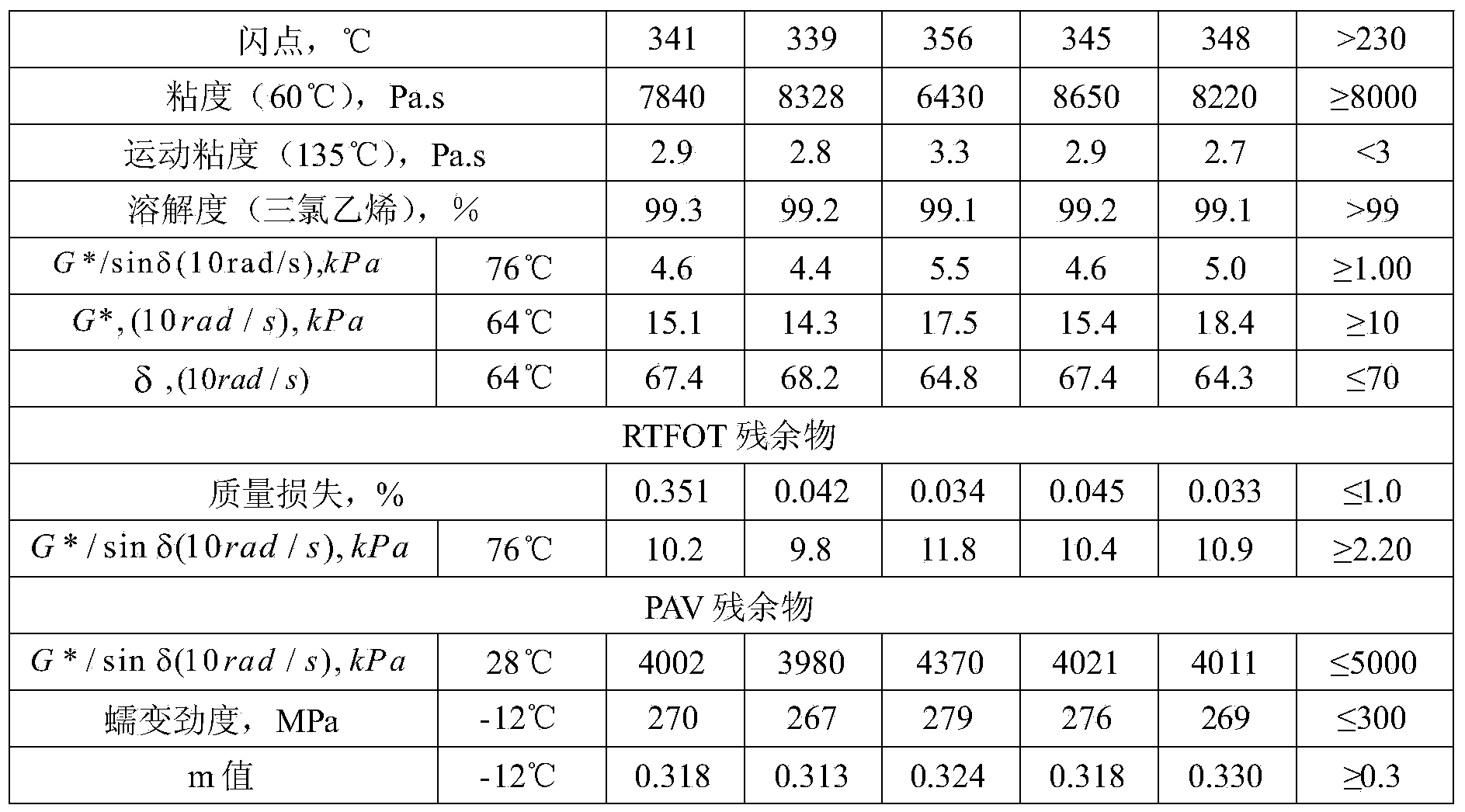

[0019] Asphalt composition: high-grade asphalt is selected from Shell No. 70 A-grade asphalt, and low-grade asphalt is selected from Karamay No. 30 A-grade asphalt; polystyrene-polybutadiene block copolymer thermoplastic elastomer is selected from Yanshan Petrochemical 4303 Star Modified agent, the molecular weight is 80,000-100,000, the molar ratio of styrene and butadiene is 1:2.33; the first auxiliary agent is selected from dibutyl phthalate, C9 resin, nitrile rubber and furfural extraction oil, the second The second auxiliary agent is polypyridine 3-methacrylate (PPy3MMA) with a molecular weight of about 17000. The mass content of each component is shown in Table 1. The polystyrene-polybutadiene block copolymer thermoplastic elastomer is the internal blending amount in the asphalt, and the additive is the external blending amount in the asphalt.

[0020] Each component content table 1 in embodiment 1-5

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com