Quick connecting piece in pile foundation static load test

A technology of static load detection and quick connection, which is applied in the direction of foundation structure engineering, foundation structure test, construction, etc., can solve the problems of heavy hanging blue, large consumption of welding rods and labor, and uneven stress of pile top reinforcement, etc., to achieve The effect of reducing work difficulty and work risk, convenient adjustment of connection position, and quick detachable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

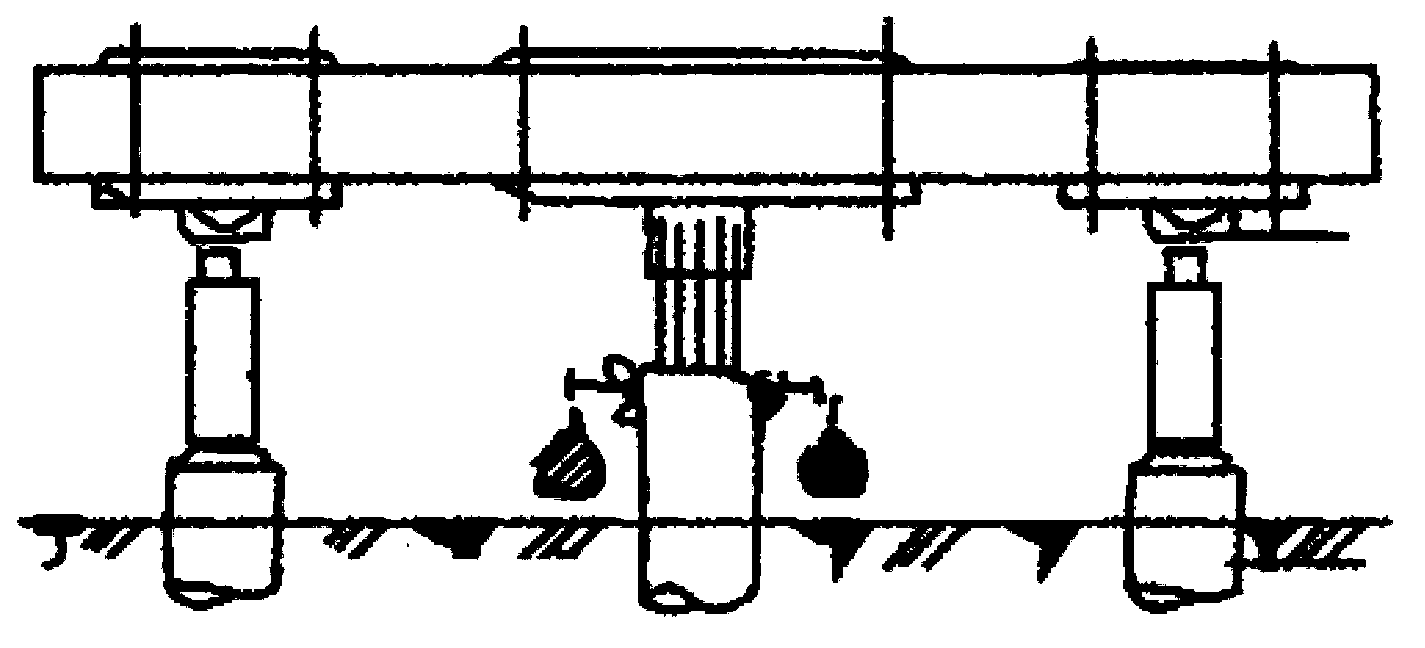

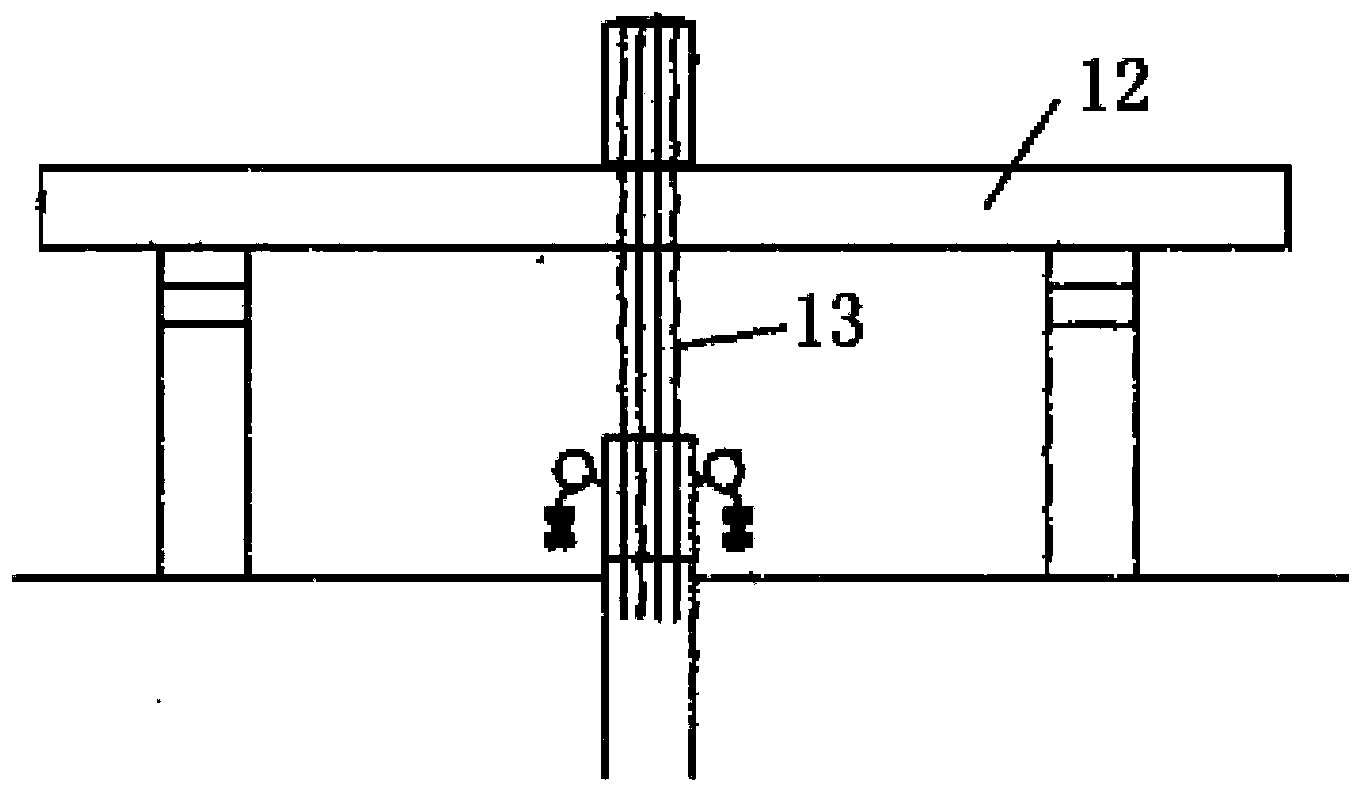

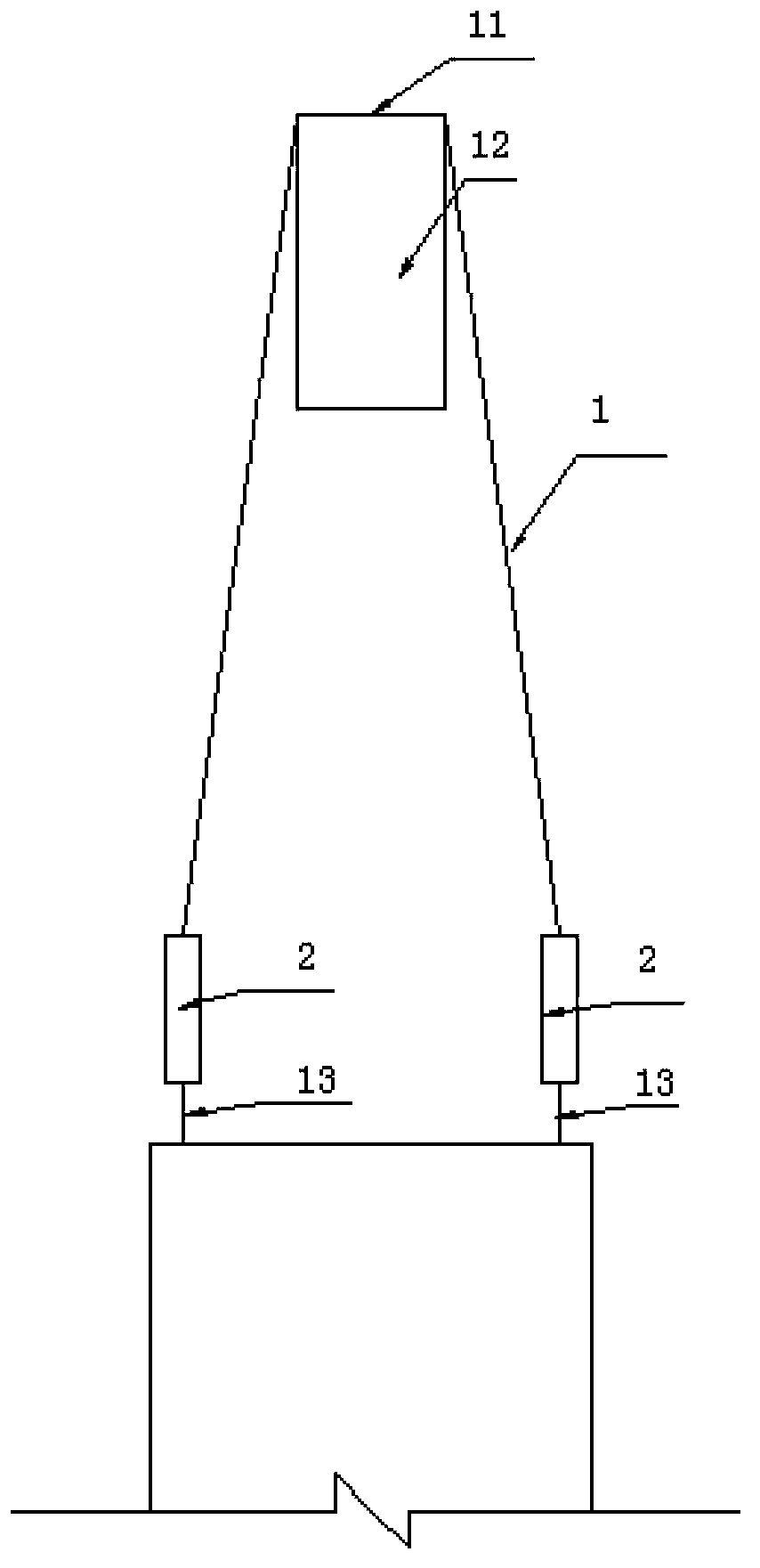

[0034] Embodiment: A quick connector for pile foundation static load detection, including a prestressed tendon 1 for connection and a sub-connector 2, at least one end of the prestressed tendon 1 for connection can be connected to the sub-connector 2 in an axial stop, The end of the sub-connector 2 facing away from the prestressing tendon 1 for connection is provided with a positioning hole 3 whose diameter can shrink, and an adjustment piece 4 is provided. The adjustment piece 4 can adjust the diameter of the positioning hole 3. When in use, the prestressing tendon 1 for connection Connect with the detection main beam 12 (when selecting the prestressed tendon 1 for connection, choose a steel bar with a thicker strength than the steel bar 13 on the pile foundation to avoid its first failure), and connect the end of the prestressed tendon 1 with the sub-connector 2 , and then insert the steel bar on the pile foundation into the positioning hole 3, use the adjustment piece 4 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com