supercharger

A supercharger and supercharger main body technology, applied in the direction of machines/engines, bearings, shafts, etc., to achieve the effect of improving oil discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

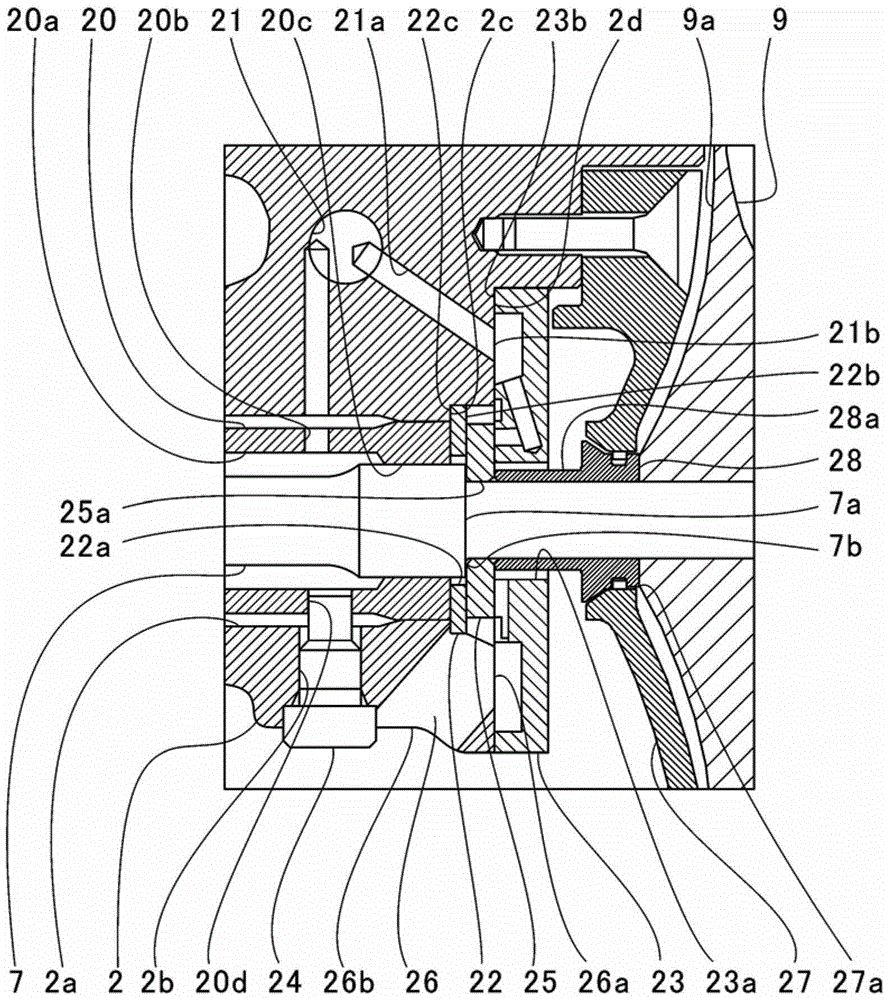

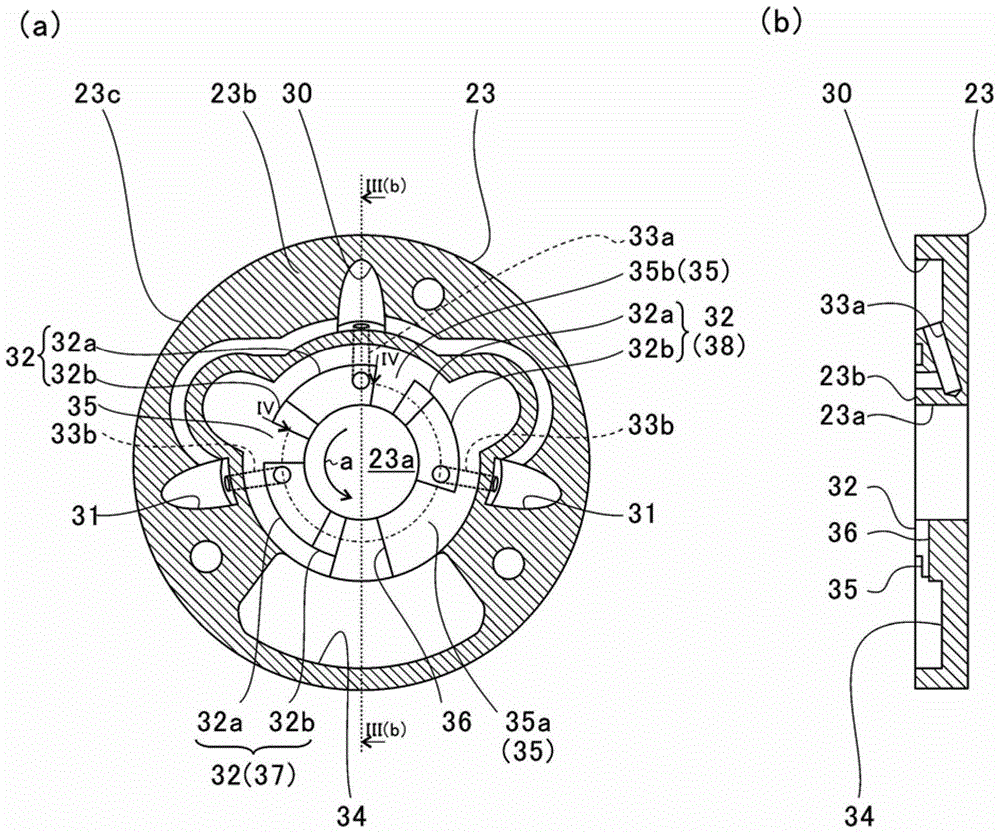

[0018] Embodiments of the present invention will be described in detail below with reference to the drawings. Dimensions, materials, other specific numerical values, and the like shown in the present embodiment are merely examples for facilitating understanding of the invention. That is, they do not limit the present invention unless otherwise specified. In this specification and the drawings, elements having substantially the same functions and structures are denoted by the same symbols to omit repeated explanations, and illustration of elements not directly related to the present invention is omitted.

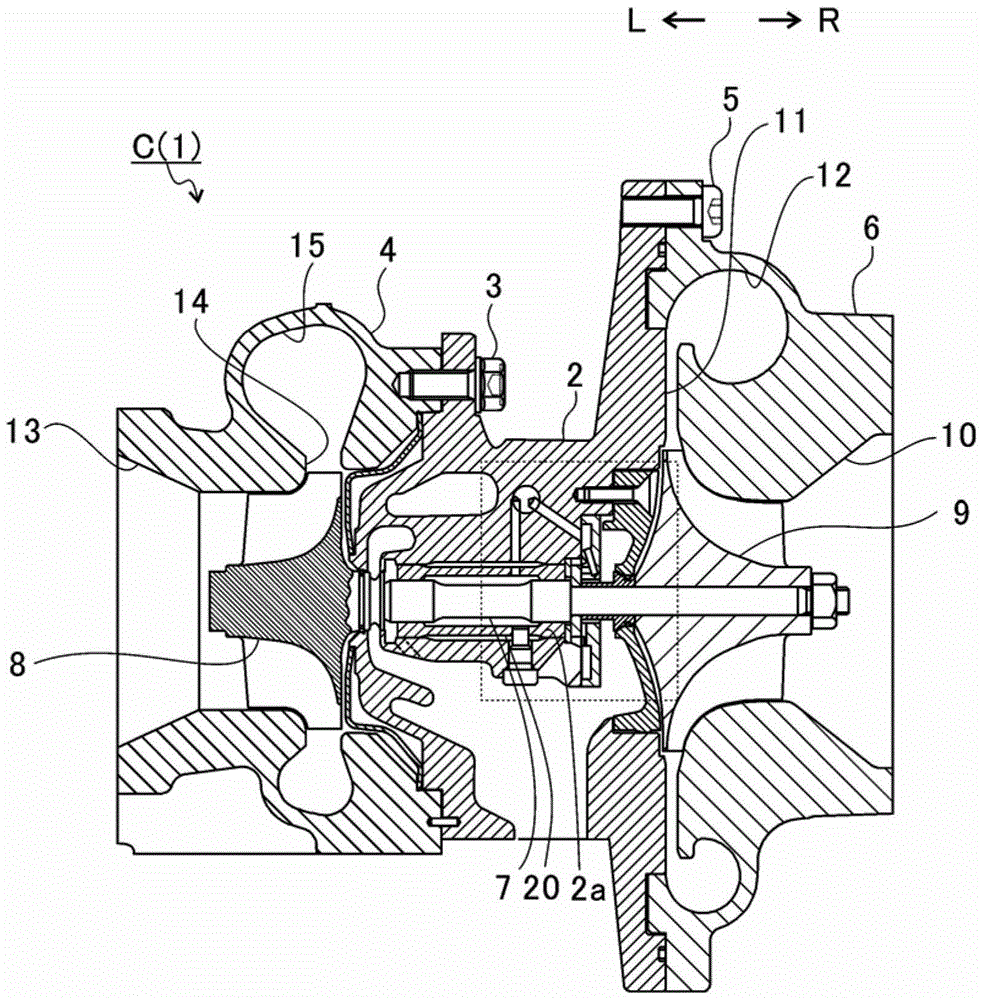

[0019] figure 1 is a schematic sectional view of the supercharger C. Below, with figure 1 The direction of the arrow L shown is the left side of the supercharger C, and the direction of the arrow R is the right side of the supercharger C. Such as figure 1 As shown, the supercharger C is configured by including a supercharger main body 1 . The supercharger main body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com