Oil discharge structure of looper mechanism on sewing machine

An oil discharge structure and technology for sewing machines, which are applied in sewing machine components, sewing equipment, textiles and papermaking, etc., can solve the problems of contaminating sutures and sewing materials, affecting the oil scraping effect, and poor effect, and achieving cost savings and oil discharge effects. Good, easy to process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

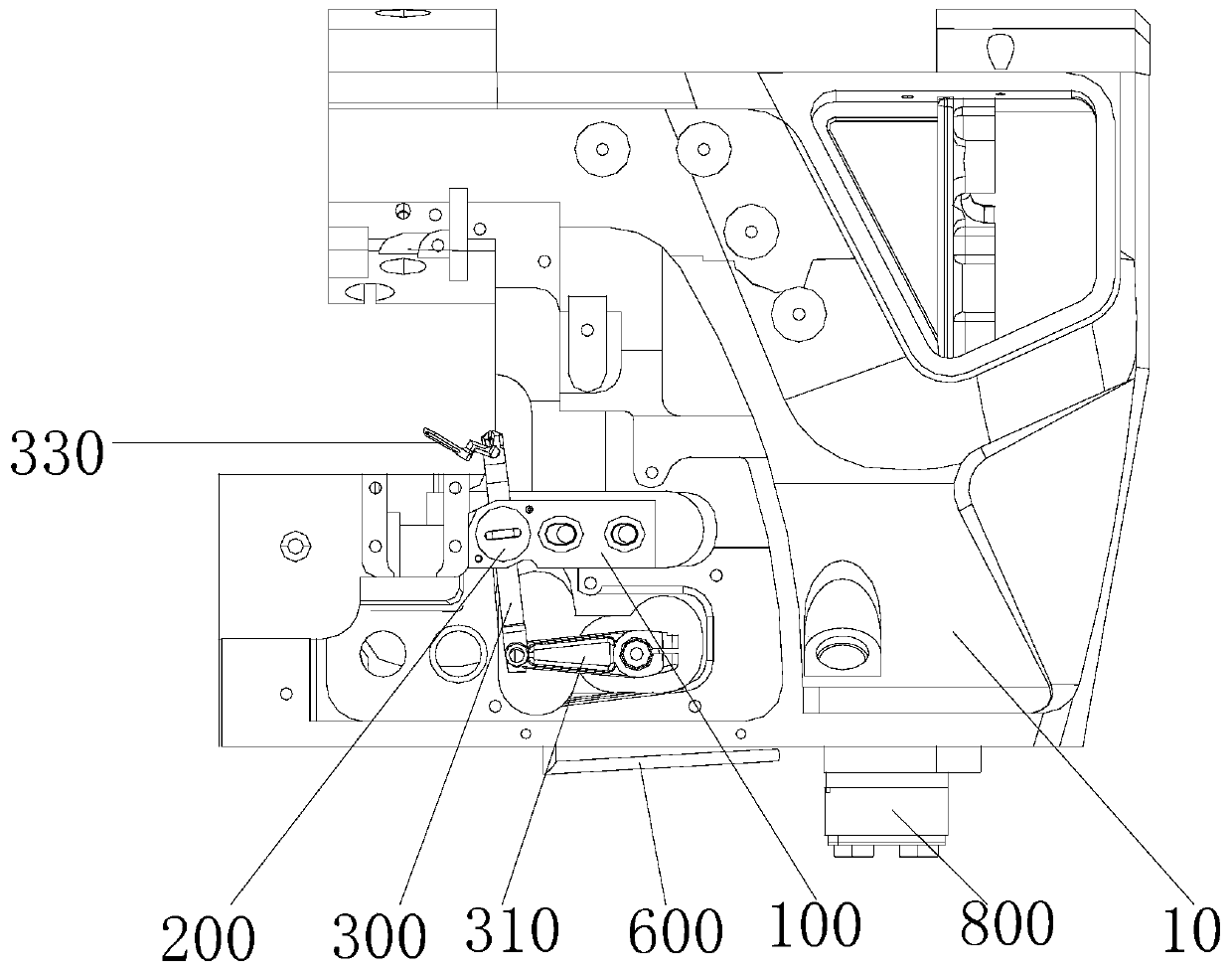

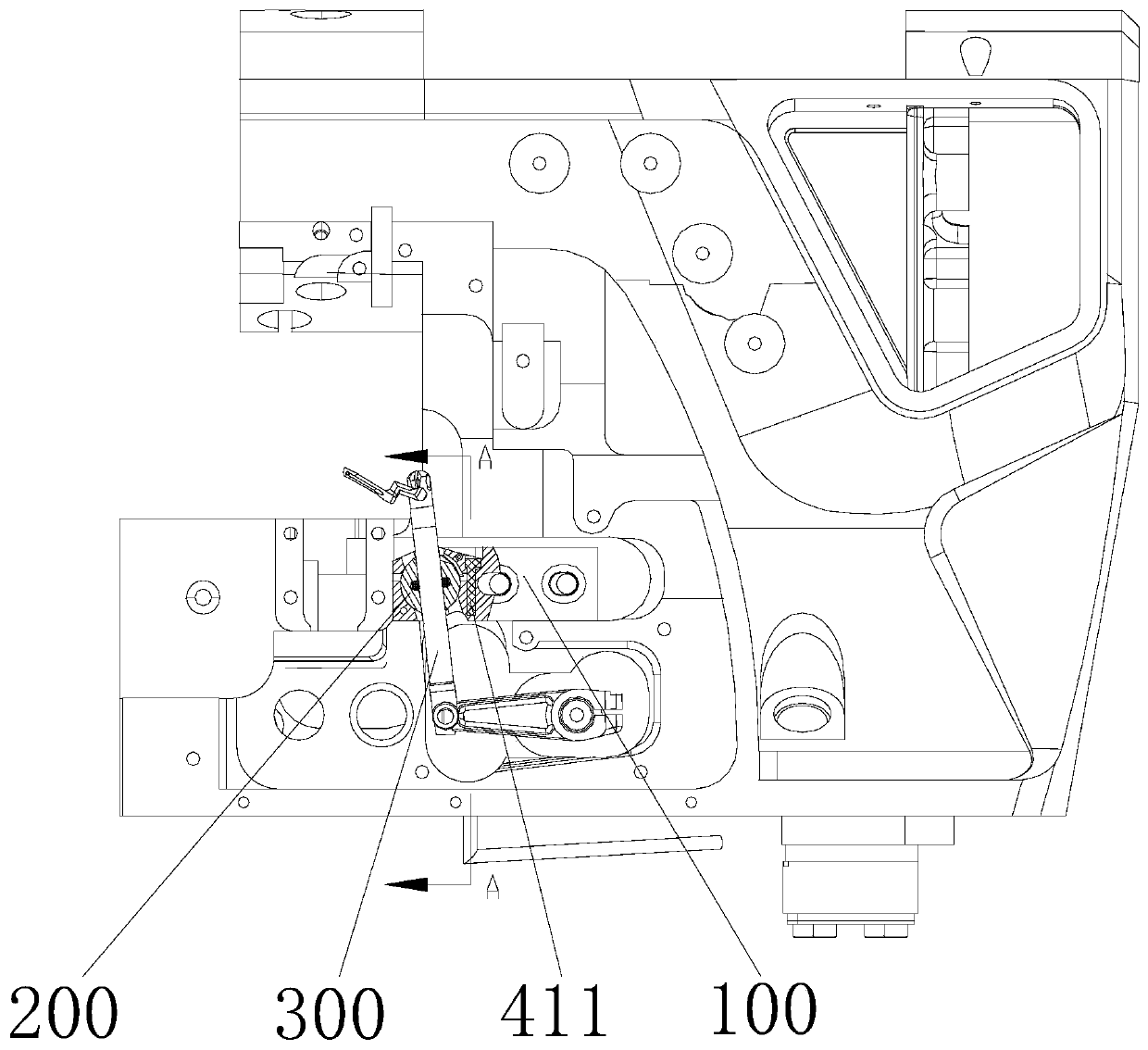

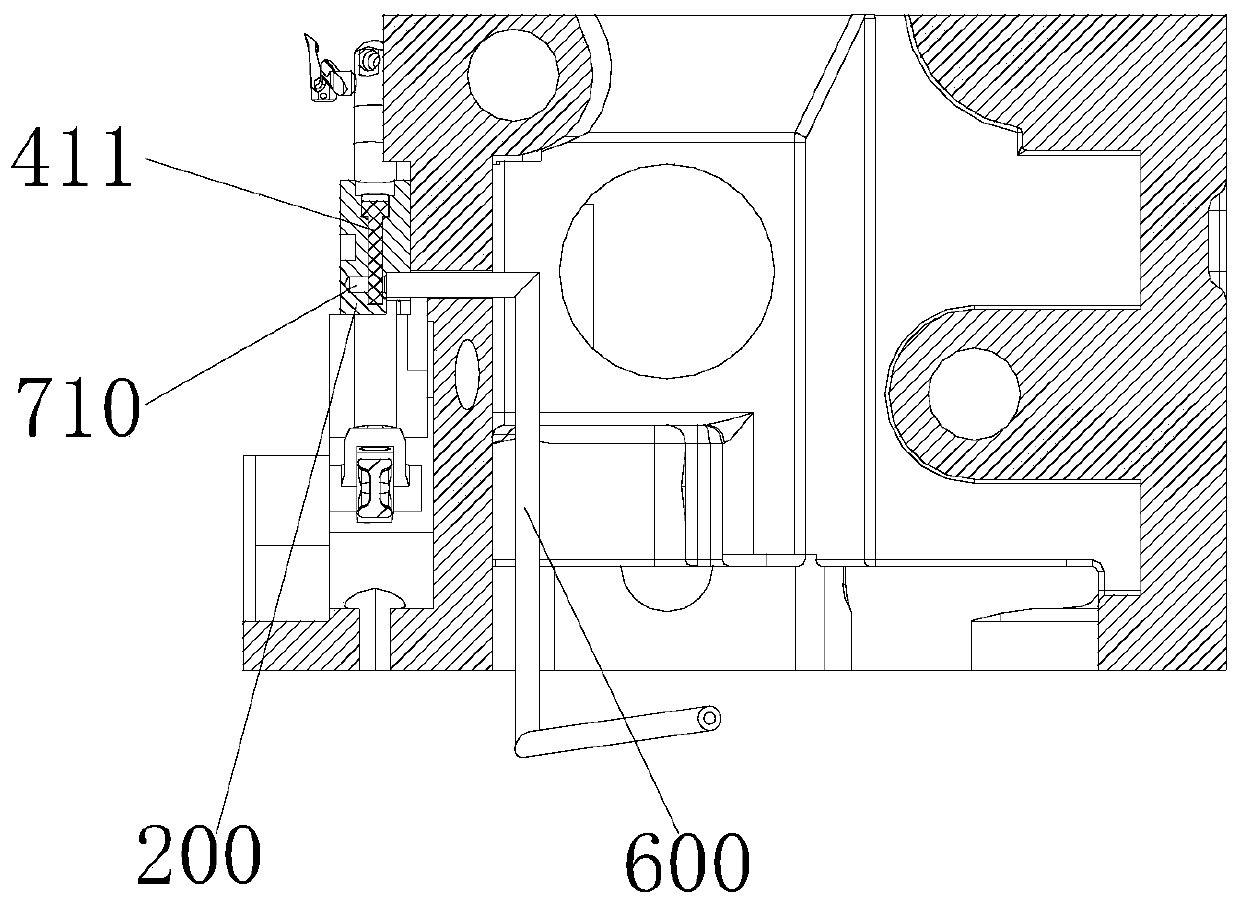

[0047] Such as Figure 1 to Figure 6 As shown, the oil discharge structure of the looper mechanism on the sewing machine in this embodiment, wherein: the looper mechanism on the sewing machine includes a slider seat 100, and the slider seat 100 is provided with a slider accommodation chamber 110 for the slider body 200 to be placed in , the slider body 200 is provided with a block through hole 210 for the upper looper slider 300 which is inclined relative to the horizontal plane to pass through;

[0048] The oil discharge structure includes: the seat body oil discharge part 400 provided on the slider seat 100 and the block oil discharge groove 500 provided on the upper surface of the slider body 200, the oil inlet end of the block body oil discharge groove 500 penetrates to the block The body through hole 210, the oil outlet end of the block body oil discharge groove 500 communicates with the seat body oil discharge part 400.

[0049] In the oil discharge structure of this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com