Three-direction displacement measurement method based on laser speckle imaging technology

A laser spot, three-direction displacement technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of large measurement errors, low work efficiency, and inability to realize automatic early warning of online monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

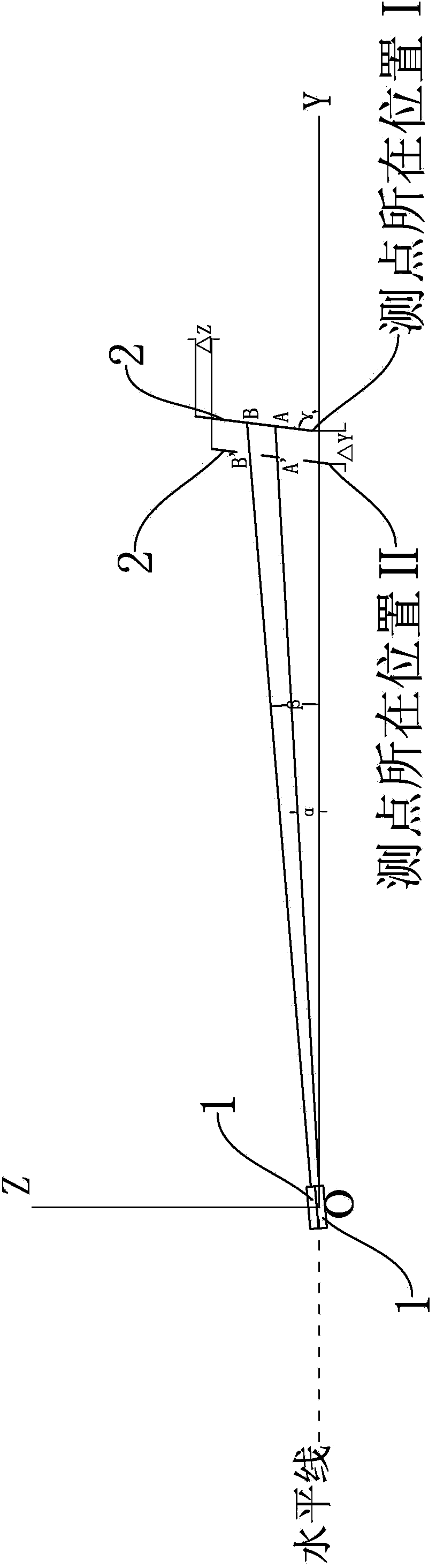

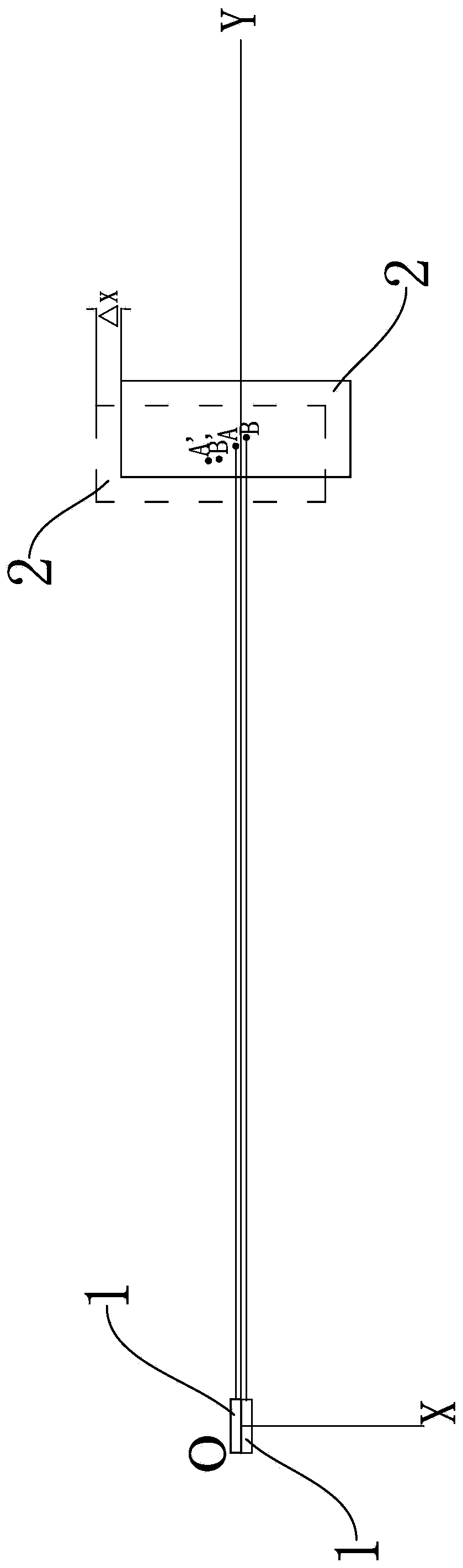

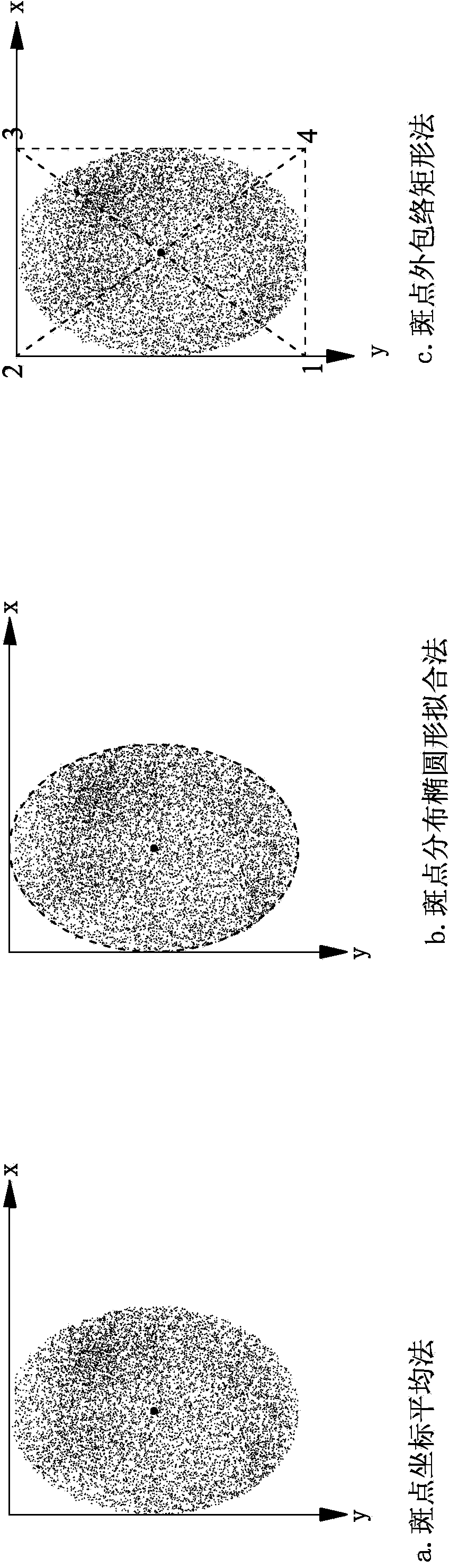

[0042] In this embodiment, two laser beams forming a certain angle are used to image on the imaging target surface 2, and the imaging center of the imaging target surface 2 and the center position changes of the two laser beams are obtained by the laser spot imaging system to calculate the position of the target surface 2. Change, so as to measure the three-way displacement of the laser emitting point and the imaging receiving point.

[0043] Such as figure 1 , figure 2 As shown, this example includes two sets of laser emitters 1 and a laser spot imaging system. The laser spot imaging system includes an imaging target surface 2, an imaging lens, an imaging optoelectronic device (CCD or CMOS photoelectric conversion device) and a signal processing unit.

[0044] The specific implementation steps of this embodiment are as follows:

[0045] 1. Install two sets of laser transmitters 1 at the reference point O, and install the laser spot imaging system at the test point I;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com