Pressure sensor chip

A pressure sensor and sensor technology, applied in the direction of measuring fluid pressure, instrument, pressure difference measurement between multiple valves, etc., to achieve the effect of preventing stress concentration, ensuring pressure resistance, and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

[0045] [Embodiment 1]

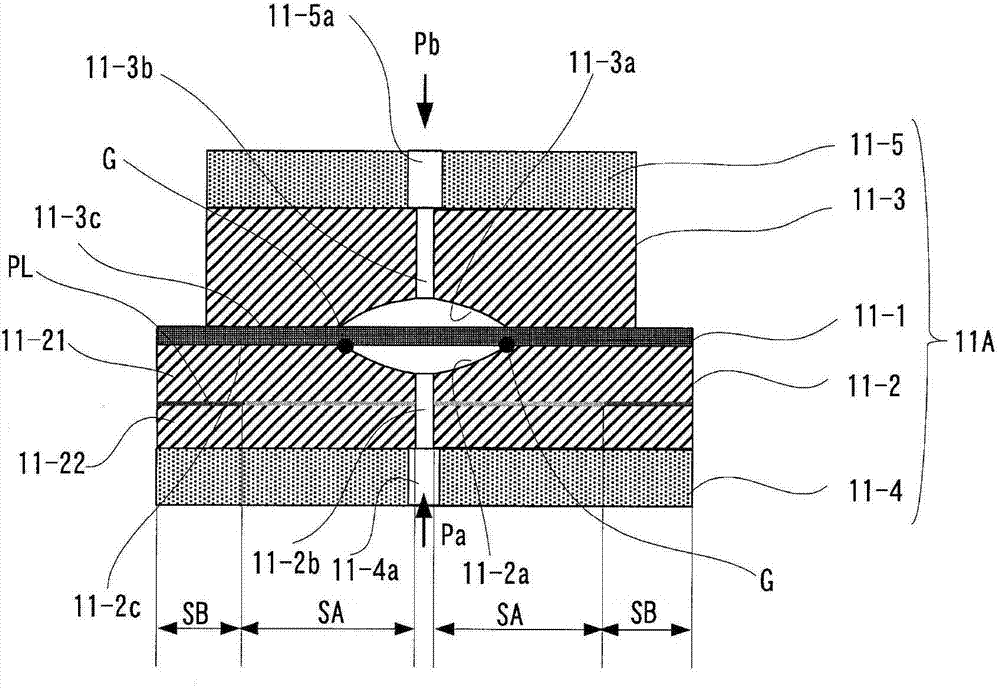

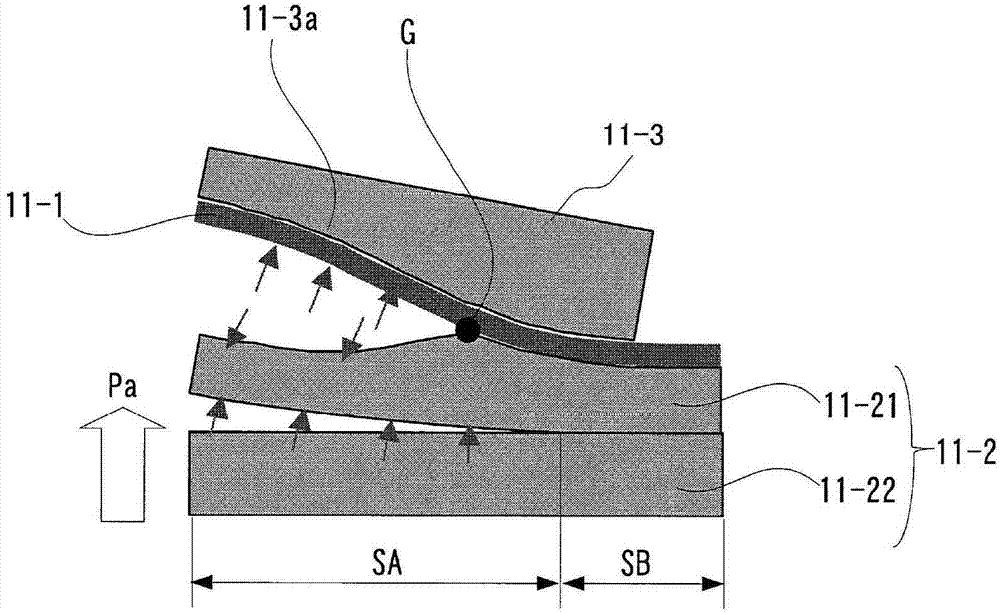

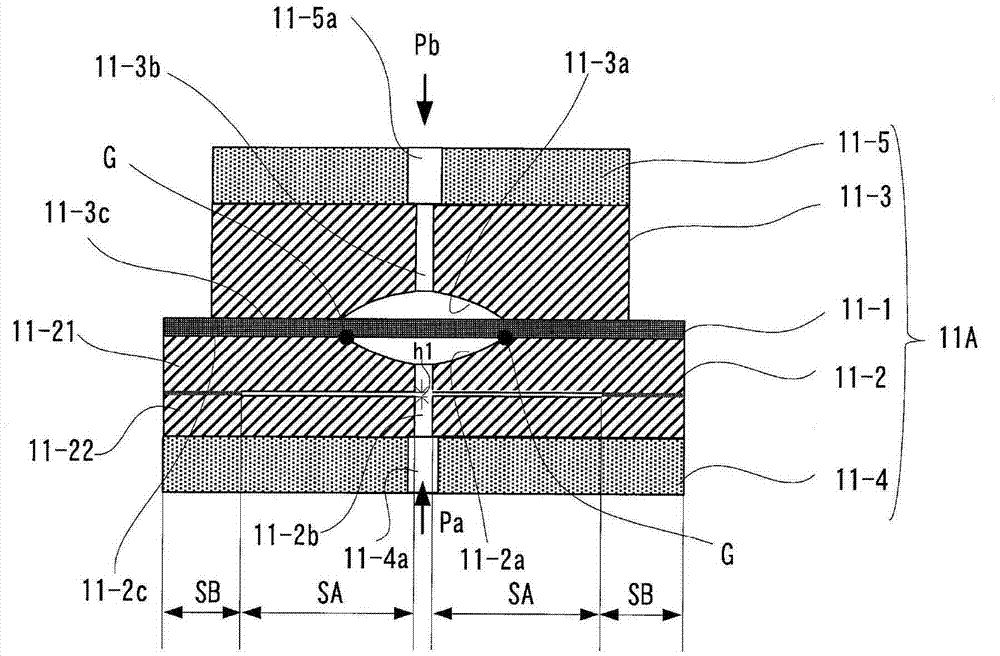

[0046] figure 1 It is a schematic diagram showing the first embodiment (Embodiment 1) of the pressure sensor chip according to the present invention. In this figure, with Figure 12 same notation as with reference to Figure 12 The description of the members that are the same as or equivalent to those described will be omitted. In addition, in this embodiment, the pressure sensor chip is denoted by symbol 11A, and Figure 12 The pressure sensor chip 11 shown in the difference.

[0047] With this pressure sensor chip 11A, the stopper member 11-2 has a non-joint area SA inside that communicates with the peripheral portion of the pressure guide hole 11-2b. This non-joint area SA is provided on a part of the surface PL parallel to the pressure receiving surface of the sensor diaphragm 11-1. The non-joining area SA is formed by roughening the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com