High voltage insulating rod detection table

A high-voltage insulation and testing bench technology, applied in the direction of testing dielectric strength, measuring device casing, etc., can solve the problems of safety tool inspection, long testing time, impact on factory production, inability to meet work needs, etc., to reduce Corona phenomenon and ozone pollution discharge, improve detection efficiency, realize the effect of work efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0009] Specific implementation manners: the present invention is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions.

Embodiment

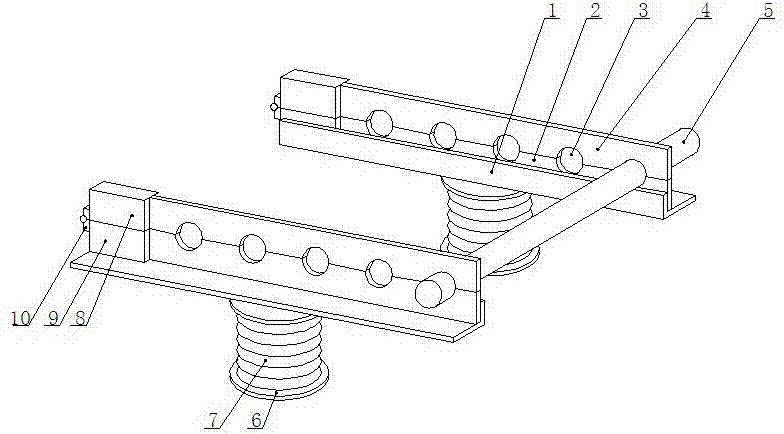

[0010] Example: such as figure 1 As shown, the high-voltage insulating rod testing platform includes a pair of clamps for clamping the insulating rod 5, and an insulating seat 7 for fixing the clamps. Said fixture comprises a pair of upper and lower splints 4,2 which can be opened and closed, and a pair of corresponding clamping holes 3 are provided on the opposite surfaces of the upper and lower splints 4,2, and the lower splint 2 is fixed on the metal base 1, and the metal base 1 Seat 1 middle part is fixed with insulating seat 7 upper ends.

[0011] The upper and lower jackets 8 and 9 are set on the same side ends of the upper and lower splints 4 and 2, and the outer surfaces of the joints of the upper and lower jackets 8 and 9 are equipped with live connectors, such as hinges.

[0012] The upper and lower splints 4, 2 are conductive metal plates, preferably aluminum plates.

[0013] The metal seat 1 is an angle iron. The clamping hole 3 is a semicircular hole, and its r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com