Novel concrete mold spraying equipment

A new type of concrete technology, applied in mining equipment, shaft equipment, earthwork drilling and mining, etc., can solve the problems of complex control action requirements and difficulty in meeting the use requirements, achieve significant economic and social benefits, improve construction efficiency and construction Quality and the effect of reducing occupational hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

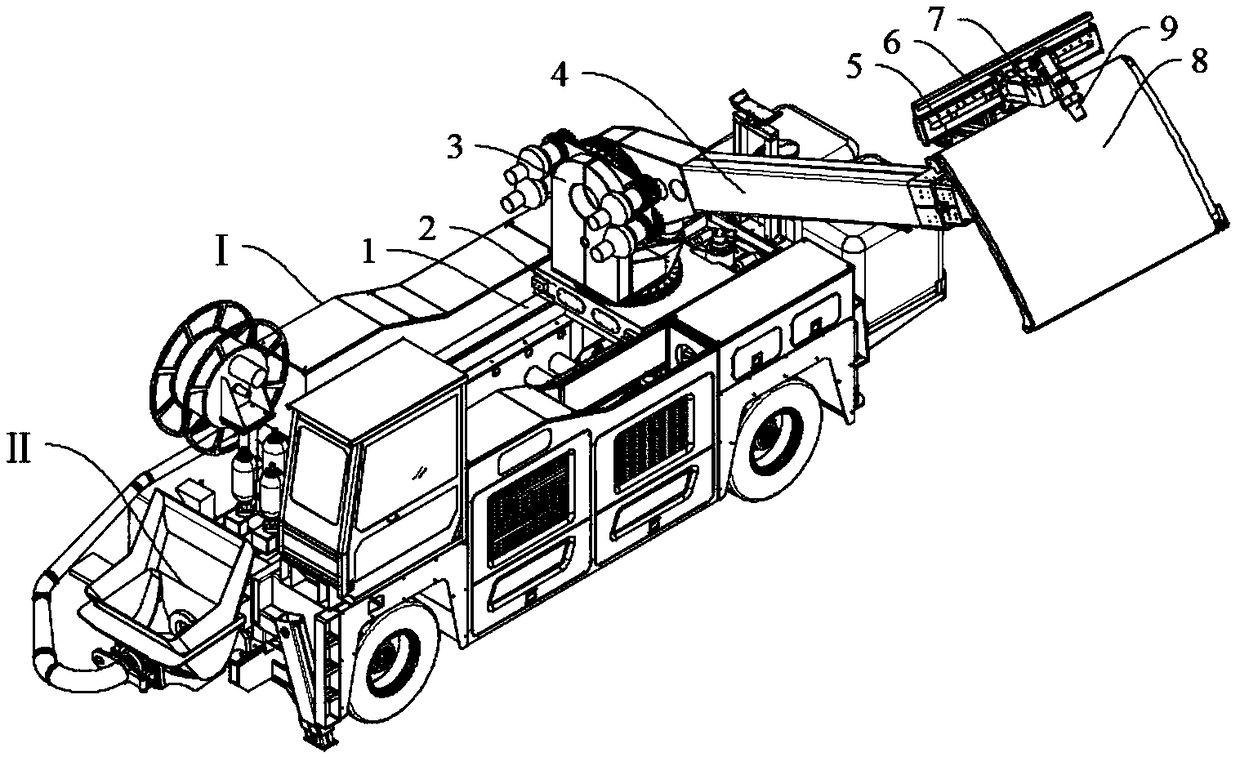

[0058] A new type of concrete spraying equipment, including a carrier mechanism I, a rotary boom 4, and a formwork mechanism 8, the template mechanism 8 is installed at the front end of the rotary boom 4, driven by the rotary boom 4, the template mechanism 8 can approach The rock surface is excavated so that the formwork mechanism 8 and the excavated rock surface form a mold cavity for the spray head assembly 9 to spray the concrete for temporary support from the direction that the transverse mold cavity is not perpendicular to the rock surface.

[0059] The spray head assembly 9 is installed on the front end of the rotating boom 4 and is located on the template mechanism 8 . Further, a forearm mechanism 5 is installed on the front end of the rotary boom 4, the template mechanism is installed on the front end of the forearm mechanism 5, and the nozzle assembly 9 is installed on the top of the forearm mechanism 5, and can slide back and forth along the longitudinal direction of ...

Embodiment 2

[0067] The mold spraying mechanism of the tunnel support layer includes a nozzle assembly 9, a template mechanism 8 and an injection system II. The nozzle assembly 9 is connected to the injection system II, and the nozzle assembly 9 is arranged above the template mechanism 8. The template mechanism 8 can The rock wall forms a mold cavity to be poured; the injection system II sends concrete to the nozzle assembly 9, and the nozzle assembly 9 injects concrete into the mold cavity in a direction not perpendicular to the rock wall above the formwork mechanism 8. The spray head assembly 9 is connected with a spray head fine-tuning mechanism, which can control the angle of the spray head 9 assembly relative to the template mechanism / cavity, so that the angle / direction of spraying the spray head assembly into the mold cavity can be adjusted.

[0068] The nozzle fine-tuning mechanism includes a pitch fine-tuning mechanism and a rotation fine-tuning mechanism, wherein the nozzle assembl...

Embodiment 3

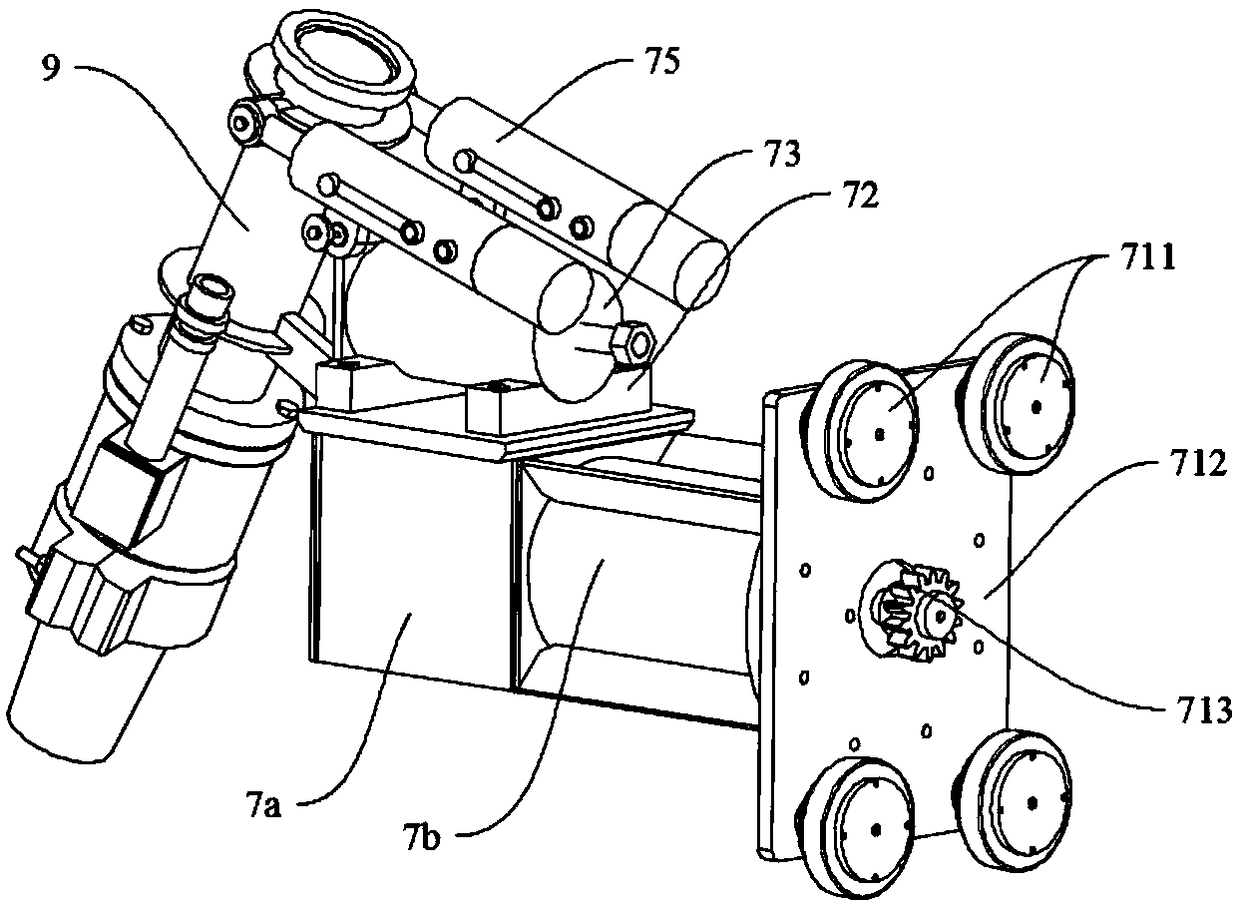

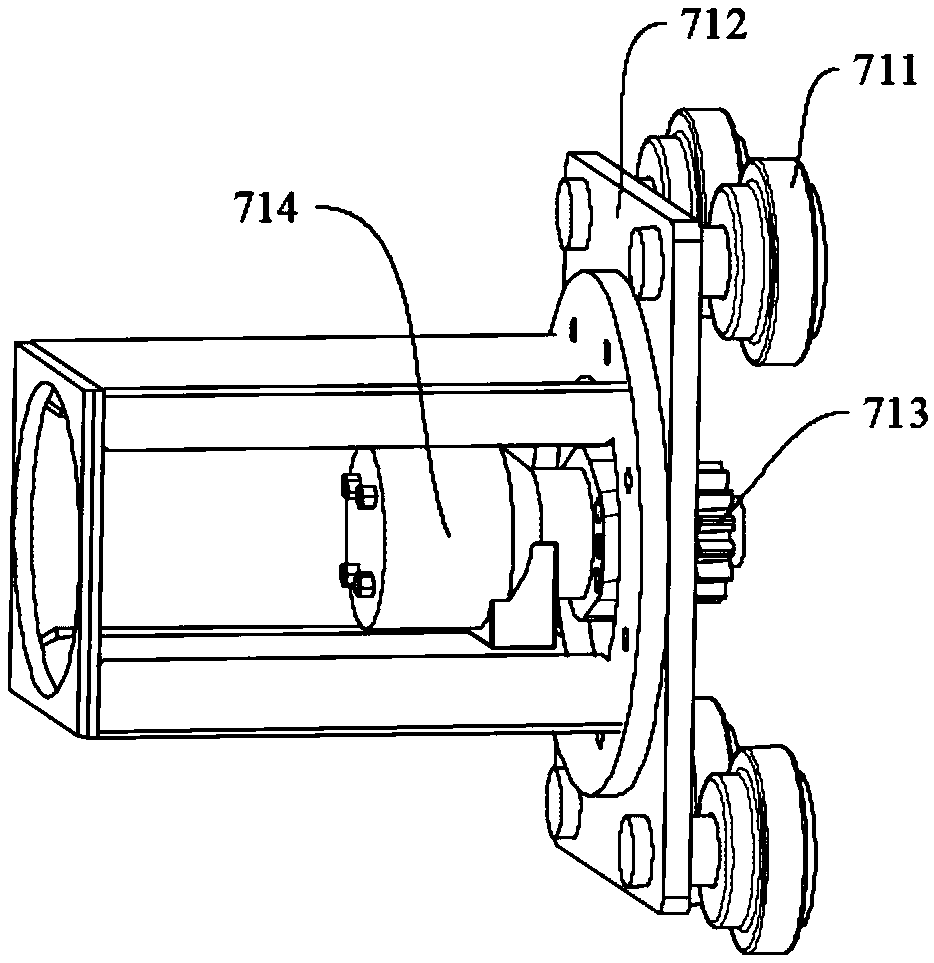

[0072] This embodiment provides the specific structure of the nozzle fine-tuning mechanism on the basis of Embodiment 1. The nozzle fine-tuning mechanism includes a pitch fine-tuning mechanism and a rotation fine-tuning mechanism, wherein the nozzle assembly 9 is connected to the pitch fine-tuning mechanism and / or the rotation fine-tuning mechanism; The pitch fine-tuning mechanism can adjust the pitch angle / direction of the spray head assembly 9; the rotation fine-adjustment mechanism can adjust the rotation angle / direction of the spray head assembly 9; The angle / orientation relative to the cavity to ensure the effect and quality of injection casting.

[0073] The fine-tuning mechanism also includes a nozzle fixing seat 7, and the rotary fine-tuning mechanism is fixed on the nozzle fixing seat 7; the pitch fine-tuning mechanism and the nozzle assembly 9 are all arranged on the rotary fine-tuning mechanism, and the pitch fine-tuning mechanism and the nozzle assembly 9 are integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com