Workshop-level data integration system for electrolytic aluminum factory

A technology of data integration and electrolytic aluminum, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of separation of management informatization and production automation, and achieve the effect of data exchange and sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

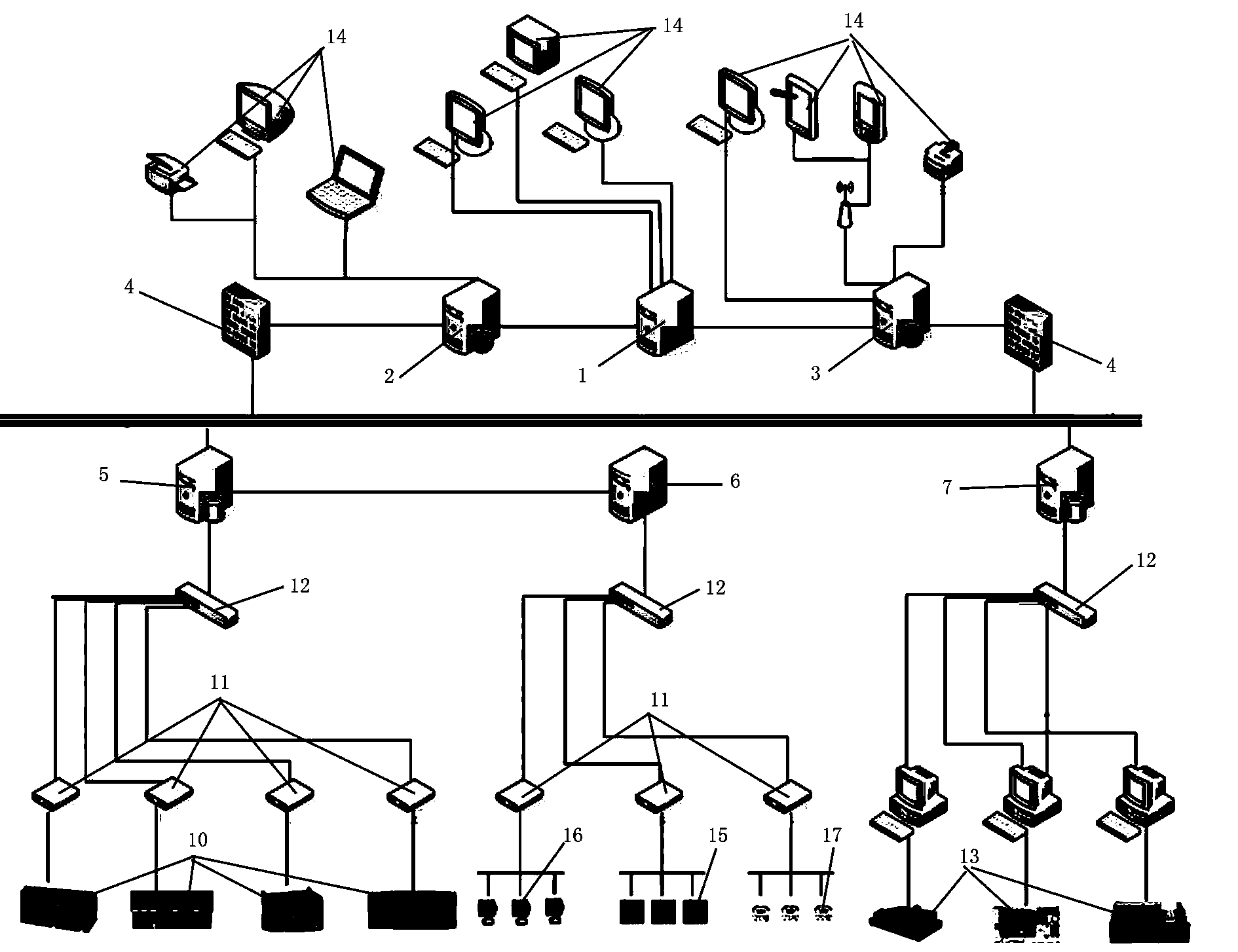

[0018] As shown in the figure, the present invention is a workshop-level data integration system for electrolytic aluminum plants, including control system data integration, laboratory analysis data integration, and production process data integration, and integrates control system data, laboratory analysis data, and production process data. The data of the control system is sent to the enterprise application server 1; the control system data integration is to integrate the data in the PLC control system and the automation equipment 10 in each workshop of the electrolytic aluminum plant through the real-time database 5; the laboratory analysis data integration is to use the relational database 7 to test The data collected by the analysis equipment is integrated; the production process data integration is to integrate the process parameters, equipment operation status and dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com