Programmable controller having a heatsink

A technology of programming controllers and heat sinks, applied in logic controllers for automation/industrial process control, circuit heating devices, modification through conduction heat transfer, etc., can solve problems such as increased power loss, and achieve small structural size , multi-power loss, and the effect of reducing the cost of installation devices and additional tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

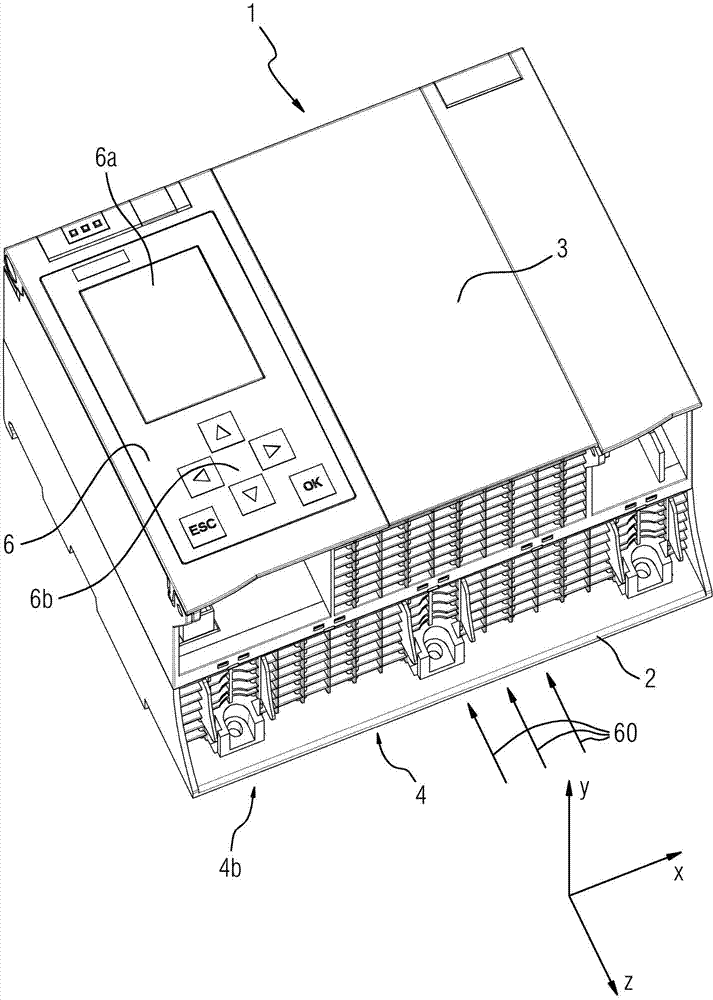

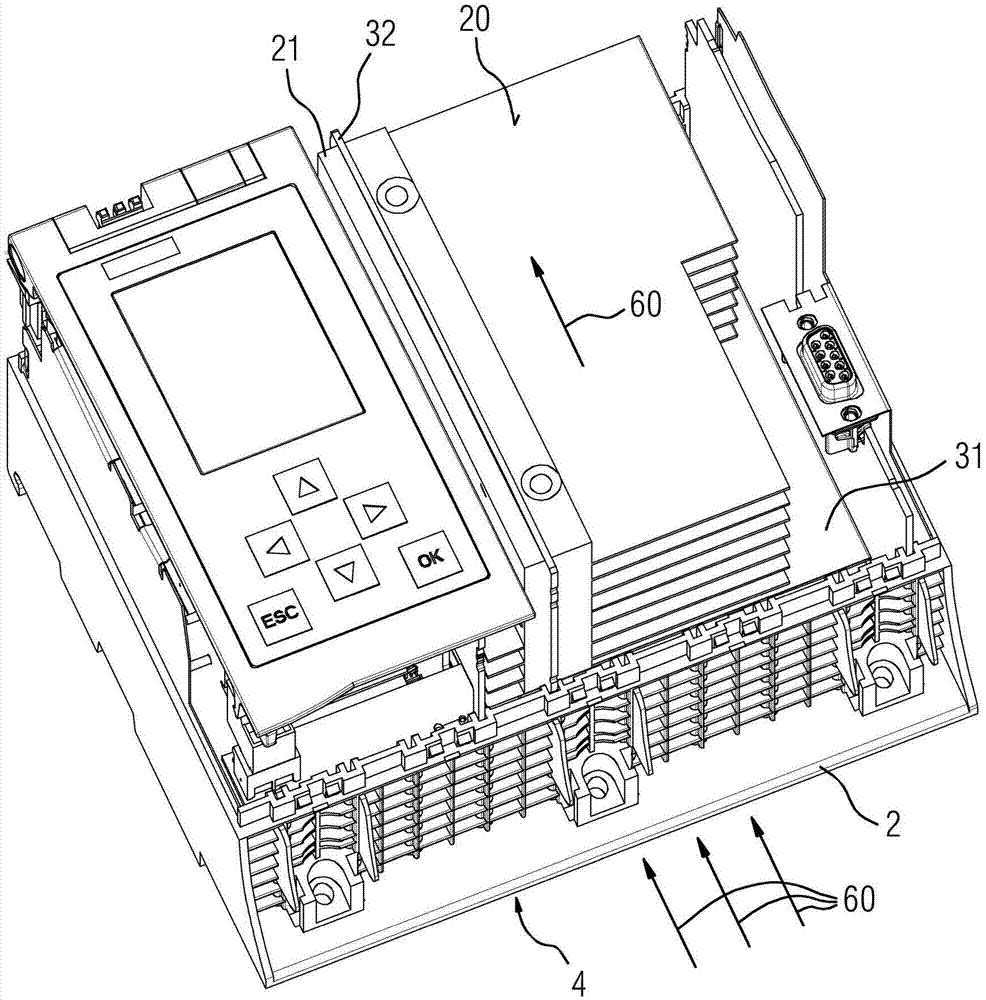

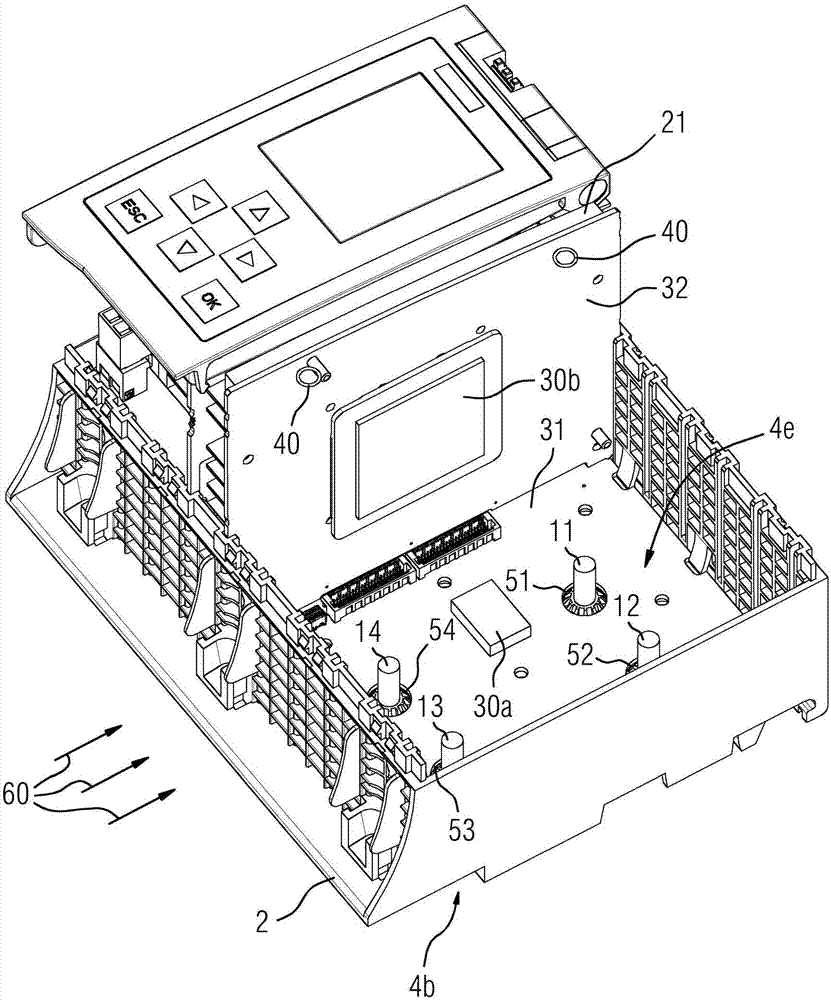

[0023] according to figure 1 Consists of a programmable controller for industrial process automation designed for use in applications in the field of automation. Since programmable controllers are exposed to harsh environmental conditions, such as humidity, temperature differences, vibration loads and shock loads, this programmable controller must be designed to be particularly robust. The shown programmable controller 1 has a base housing 2 and a front cover 3 , wherein a front cover 6 with an integrated display 6 a and an integrated operating panel is additionally shown.

[0024] Three spatial axes x, y, z are shown below the programmable controller 1 . The programmable controller 1 and in particular the internal structure of the programmable controller 1 are displaced on the spatial axes x, y, z in the event of shock loads, vibration loads or vibration loads. in from figure 1 A ventilation grille can be seen in the perspective view of the programmable controller 1 , whic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap