Powder mixing device

A mixing device and powder technology, applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problems of uneven mixing of raw materials, long stirring time, etc., achieve short stirring time, prolong service life, and uniform mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

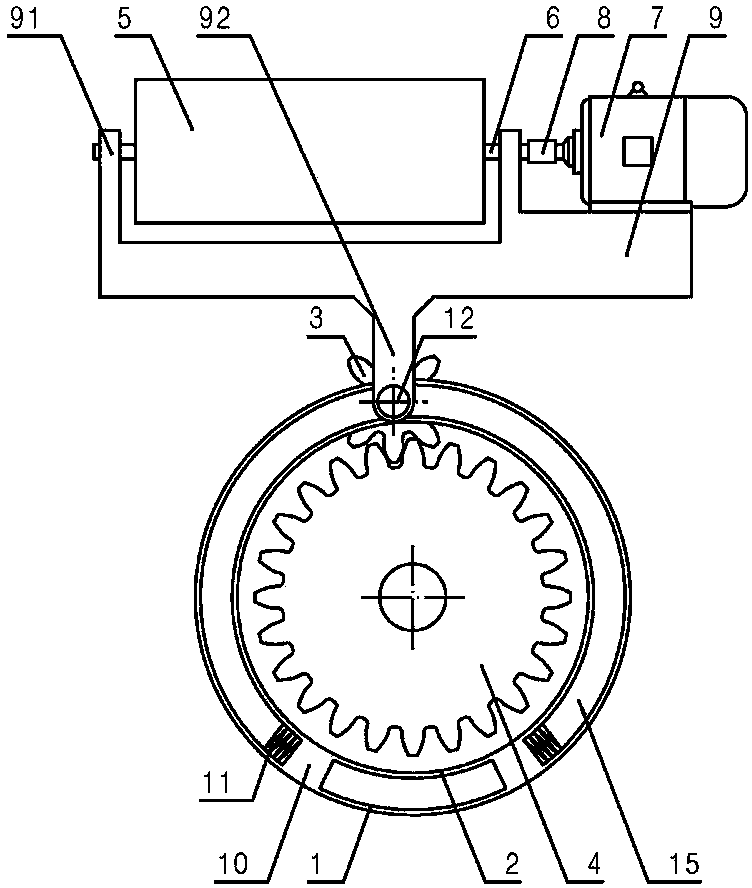

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

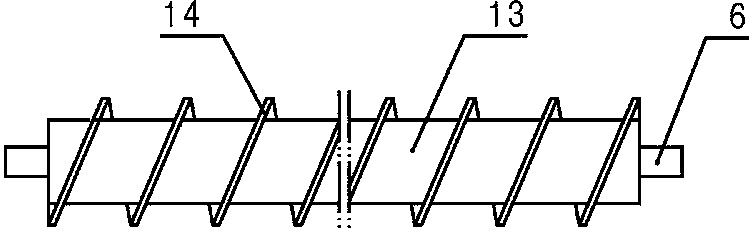

[0014] like figure 1 As shown, a powder mixing device according to the present invention includes: a support 9, an airtight mixing cylinder 5, and a rolling seat formed by a concentric inner cylinder 2 and an outer cylinder 1, and the two ends of the airtight mixing cylinder 5 are respectively A rotating shaft 6 is provided, and a pair of lugs 91 are provided on the support 9, and the pair of rotating shafts 6 are respectively arranged on the corresponding side of the support through bearings (conventional technology, not shown in the figure). On the ear 91, the support 9 is also provided with a geared motor 7 as a power device on one side of the closed mixing tube 5, and the output shaft of the geared motor 7 is connected to the corresponding side of the closed mixing tube 5 through a coupling 8. A pair of support arms 92 are provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com