Extrusion mold with improved structure

An extrusion die and structure improvement technology, applied in the direction of metal extrusion dies, etc., can solve the problems of difficult forming, rough product surface, unfavorable material forming, etc., and achieve the effect of good forming effect, high overall strength and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

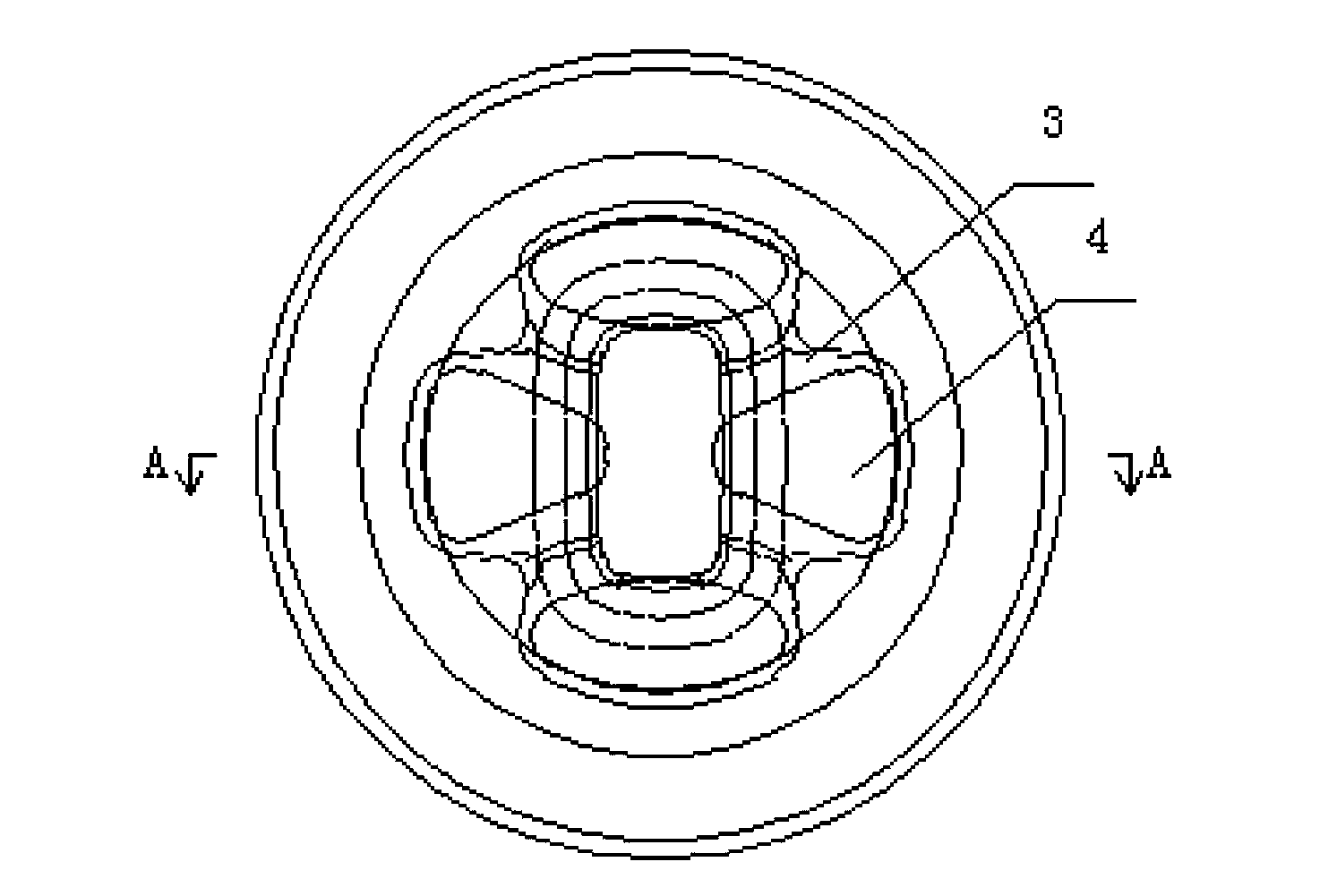

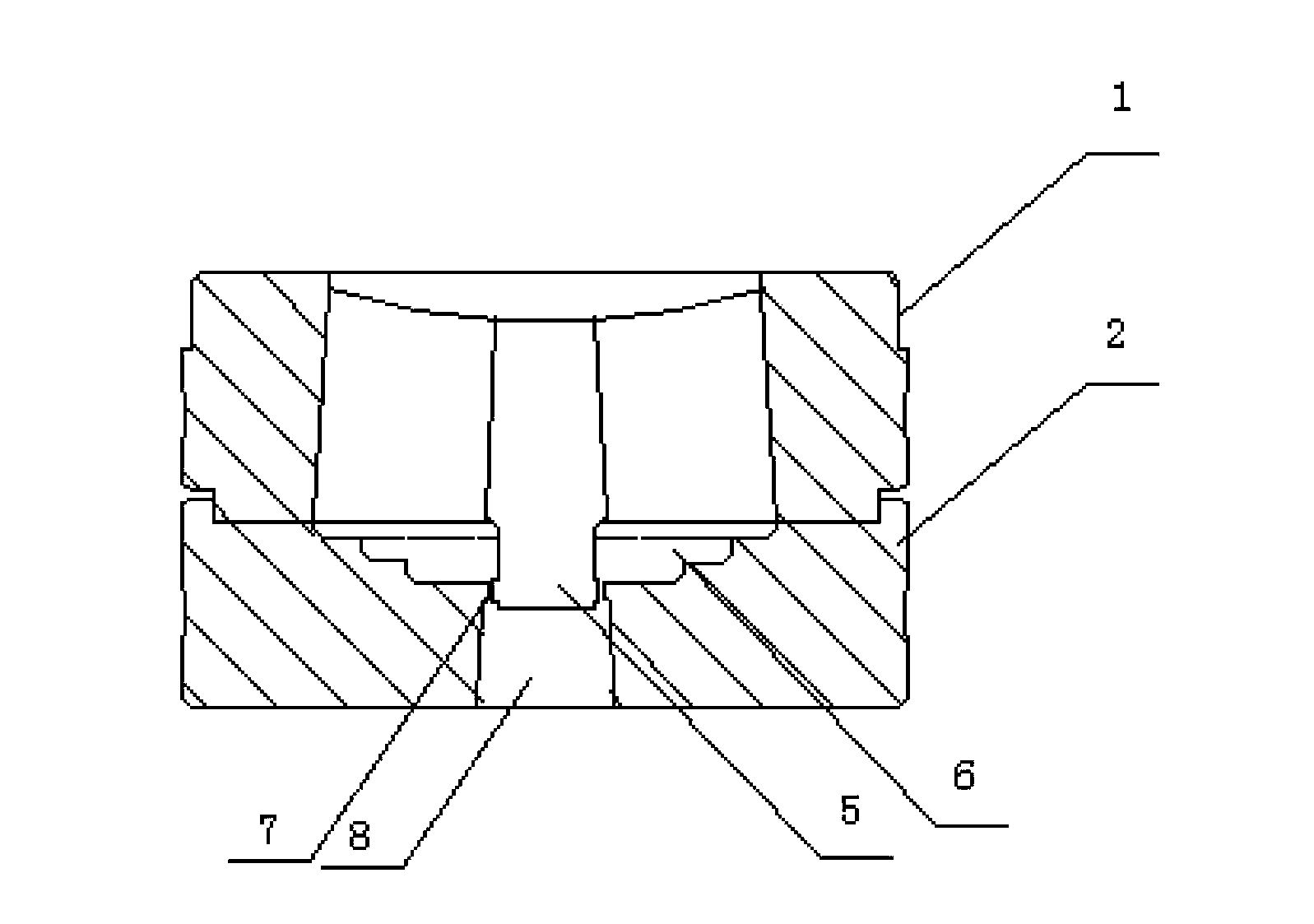

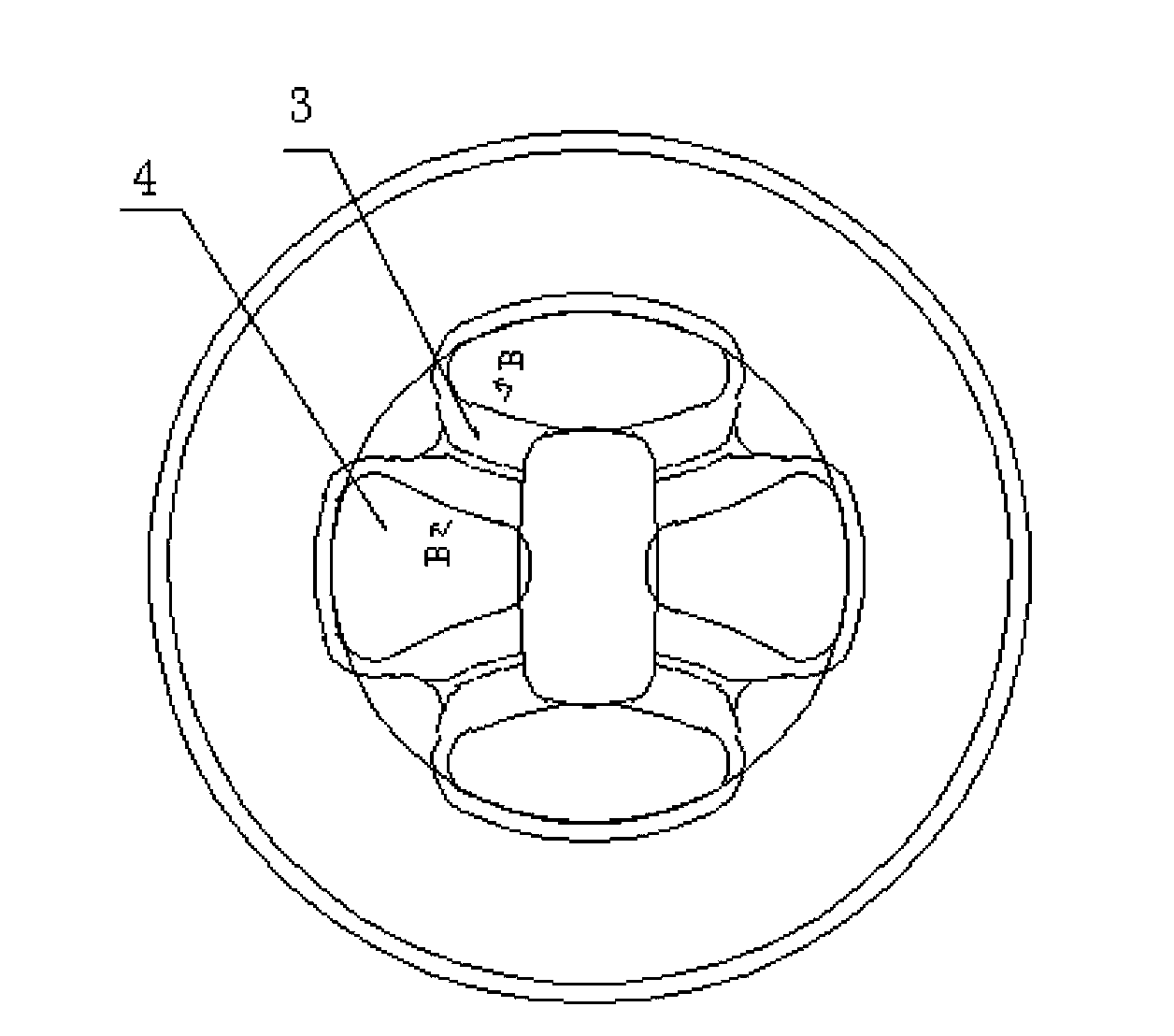

[0016] Embodiment: A structure-improved extrusion die, including a fixedly connected upper die 1 and a lower die 2, the upper end of the upper die 1 is provided with a deflector, the deflector is provided with a bridge 3, and the edge of the bridge 3 Both sides are provided with chamfering structures, and the bridge positions 3 are formed with diversion holes 4, and the core head 5 is provided under the deflector of the upper mold 1, and the lower mold 2 is sequentially provided with connected welding chambers 6, The forming hole 7 and the discharge hole 8, the welding chamber 6 communicates with the split hole 4 of the upper mold 1, the core head 5 of the upper mold 1 is inserted in the forming hole 7 of the lower mold 2, the lower mold 2 The welding chamber 6 is composed of at least two stages of welding chambers 6, and the welding chambers 6 of each stage are arranged in a stepped state with tapered diameters. The material enters from the upper end of the upper mold 1 and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com