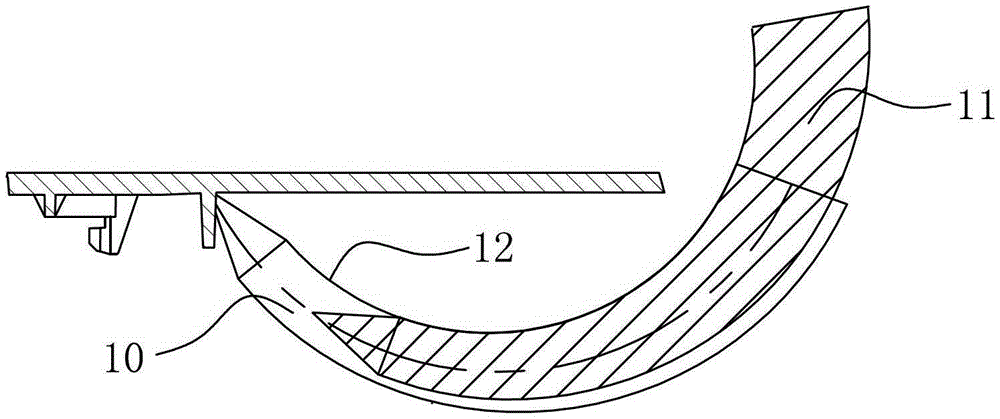

Three-stage horn gate

A horn gate, three-stage technology, applied in the field of gate forms, can solve the problems of unsmooth demoulding of the material head 11, easy deformation of the material head 11, film pulling and deformation, etc., so that it is not easy to deform and break, reduce The effect of molding cycle and effective demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

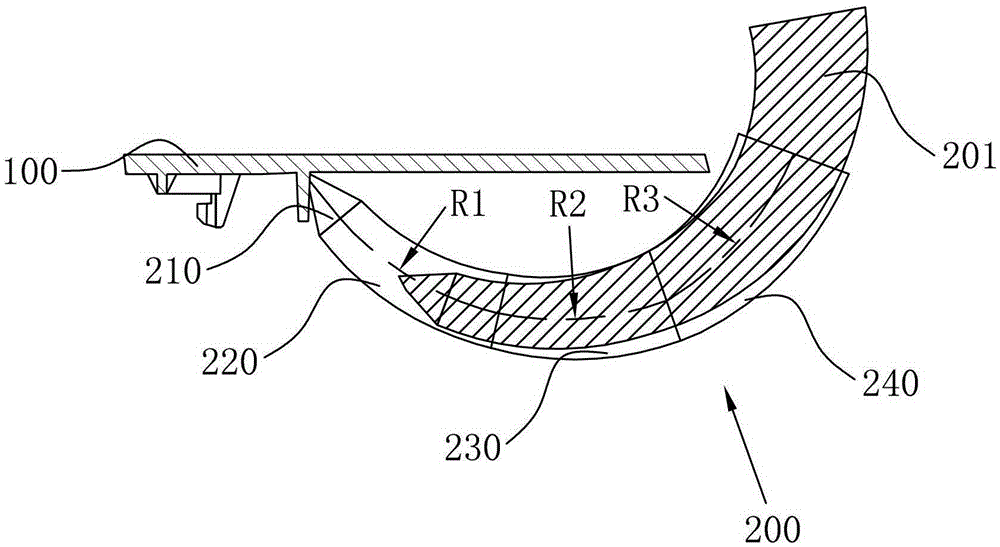

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The three-stage horn gate of the anti-drawing die provided by the present invention is applied to products that require latent glue feeding in the mold, please refer to figure 2 As shown, 100 is a product that requires latent glue injection. The horn gate 200 is shaped like a horn-like curved cone and its cross-sectional size gradually decreases. The horn gate includes:

[0021] Front gate 210, which is located at the joint between the horn gate 200 and the product 100;

[0022] The first gate 220 is connected to the front gate 210, the center line of the first gate 220 is a first arc, and the first arc transitions smoothly with the center line of the front gate 210, so The cross-sectional dimension of the front gate 210 is smaller than the cross-sectional dimension of the first gate 220;

[0023] The second gate 230 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com