High-speed digital inkjet printer

A technology of digital inkjet and printing devices, applied in printing devices, printing, power transmission devices, etc., can solve the problems of different colors, inability to print, nozzle clogging, etc., to prevent nozzle clogging and high printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below, a preferred embodiment of the high-speed digital inkjet printing device of the present invention will be described in detail with reference to the accompanying drawings. It should be noted that when assigning symbols to structures in the drawings, the same symbols are assigned to the same structures as much as possible even in different drawings. In addition, in the process of describing the present invention in detail, if it is considered that the specific description of related disclosed functions or structures hinders the understanding of the present invention, the detailed description will be omitted.

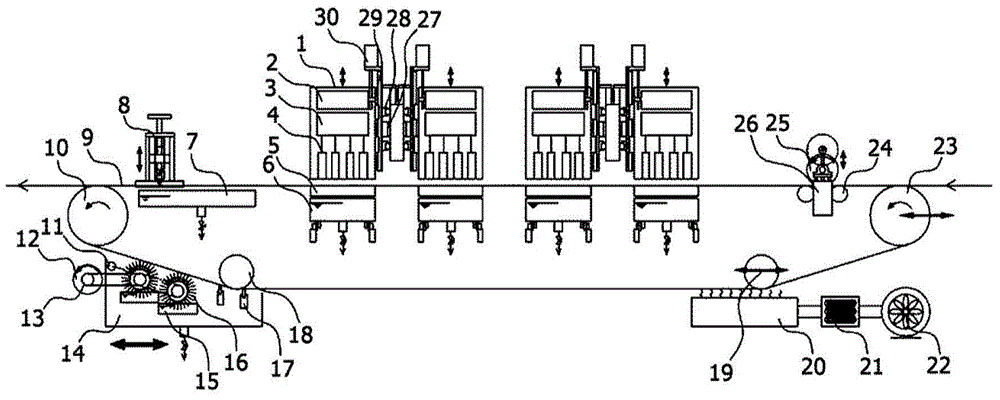

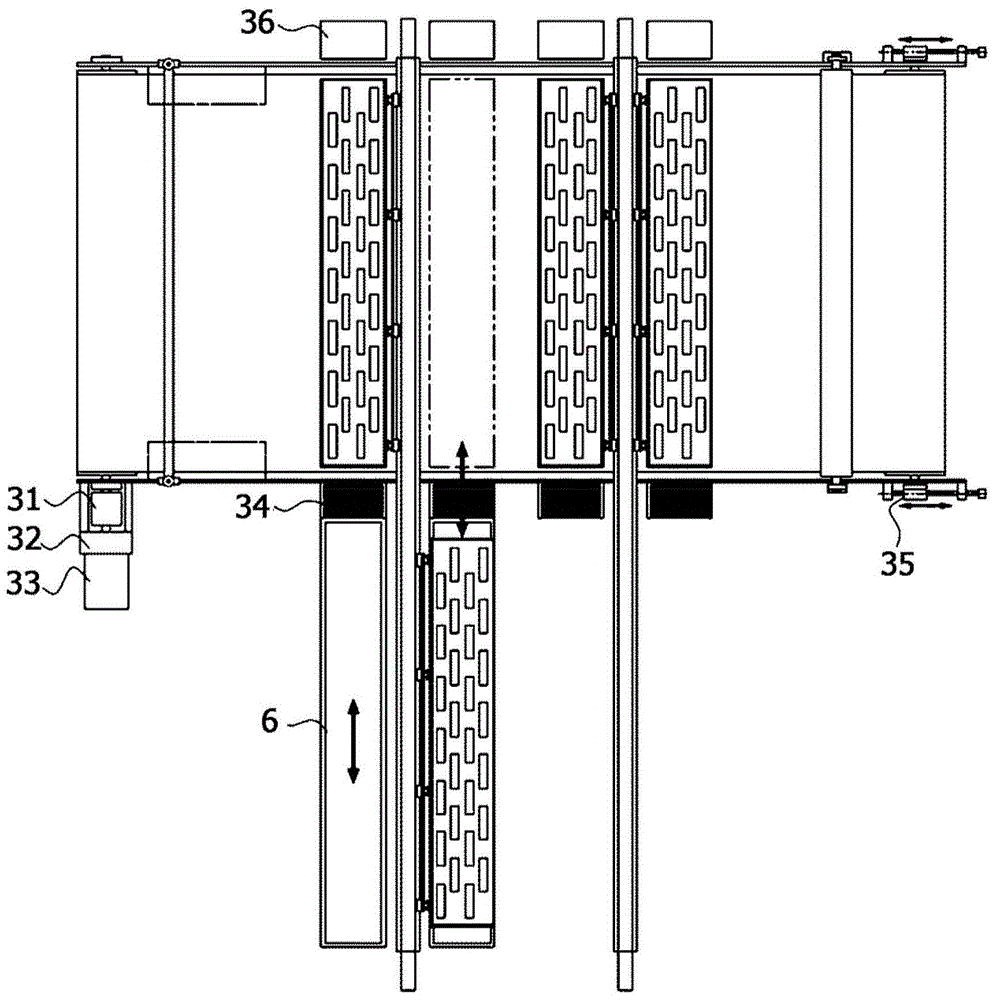

[0044] Below, combine figure 1 and figure 2 The high-speed digital inkjet printing device of the present invention will be described.

[0045] The high-speed digital inkjet printing apparatus employs a system in which the conveyor belt 9 is transferred and printed while the printing object is adhered and fixed on the conveyor belt 9 . This is a system in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com