Three-way scraping plate tilting cart

A dump truck and scraper technology, which is applied in the direction of inclined load-carrying vehicles, etc., can solve the problems of easy damage, difficult handling, and sticky substances, and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

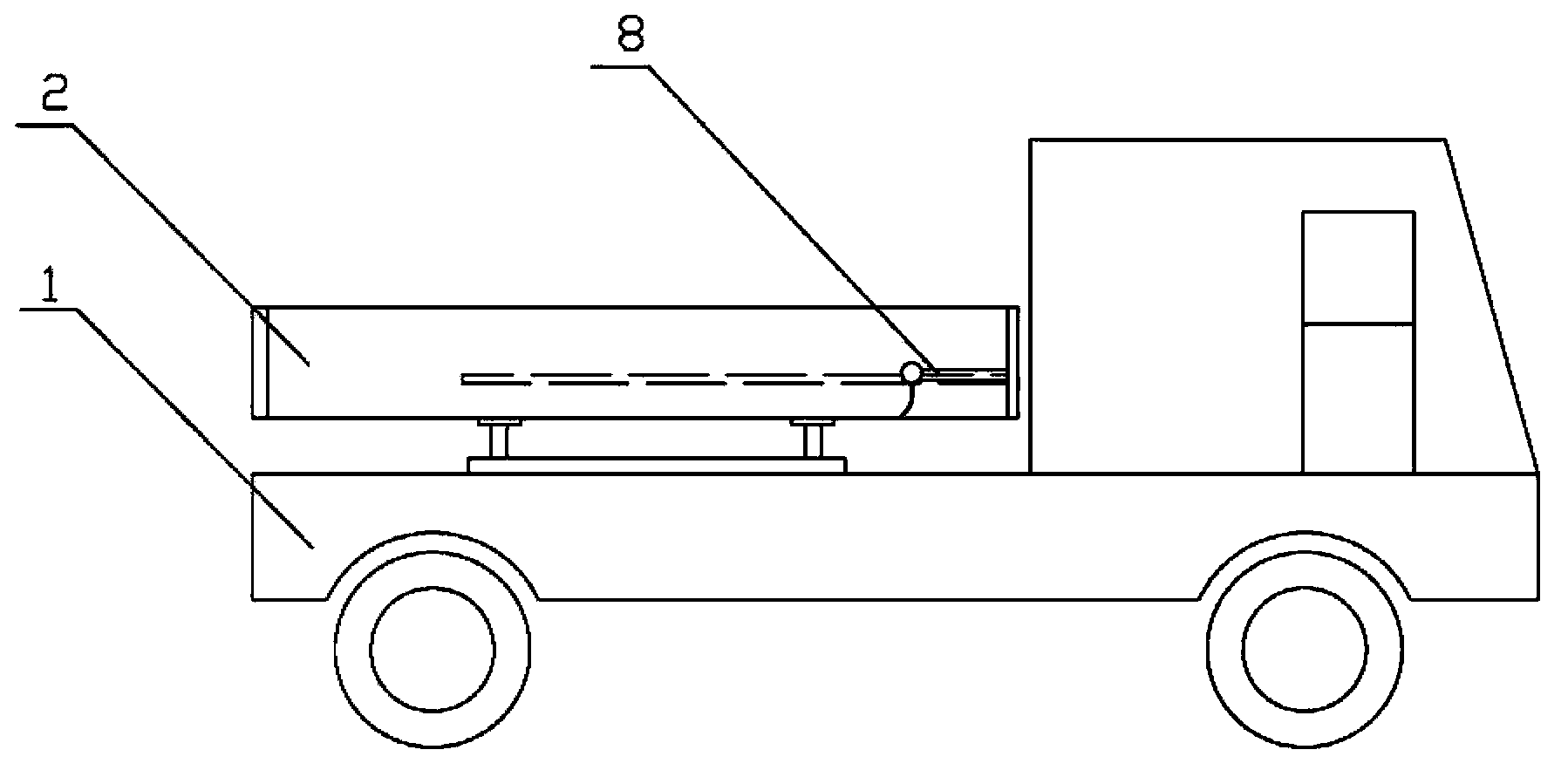

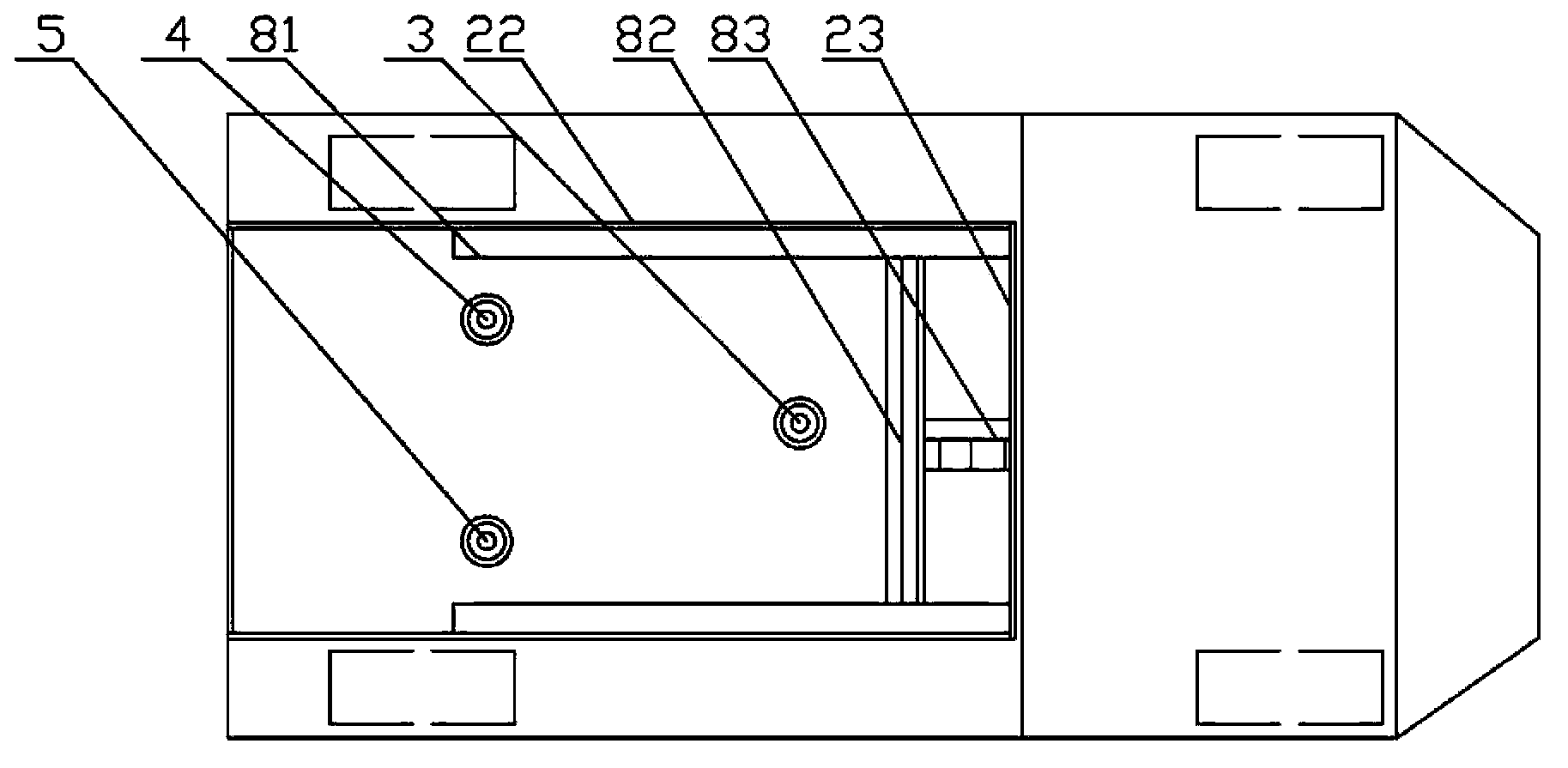

[0016] The three-way scraper dump truck includes a chassis and a cargo-carrying dump car arranged on the chassis. Three hydraulic cylinders are fixed on the chassis for pushing the dump car to complete tilting. The first hydraulic cylinder is used for connecting the center of the dump car. To push the dump car to tilt from the rear, the second hydraulic cylinder and the third hydraulic cylinder are symmetrically arranged on both sides of the first hydraulic cylinder, and are connected to both sides of the dump car to push the dump car to tilt from both sides of the rear. Personnel can intuitively complete the operation of any one of the three, avoiding the problem of constant adjustment when using the steering device and one hydraulic cylinder; at the same time, the three hydraulic cylinders can be inspected and maintained independently, relatively independently, when any one i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com