Carrying system

A technology for handling systems and objects, applied in the field of handling systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

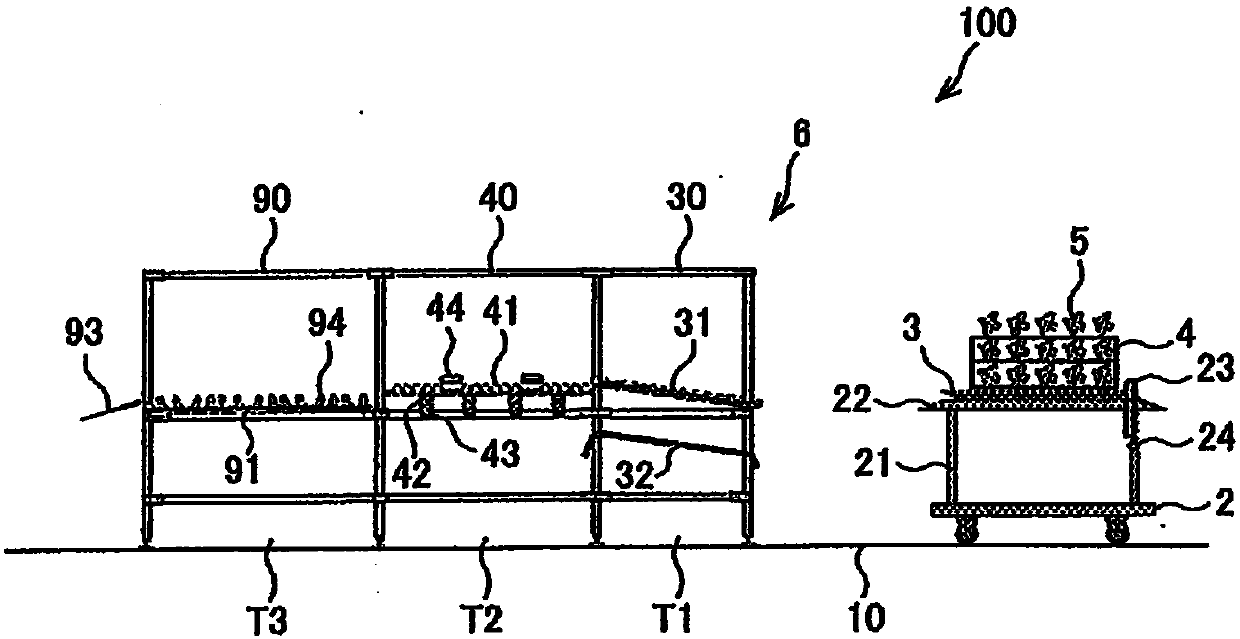

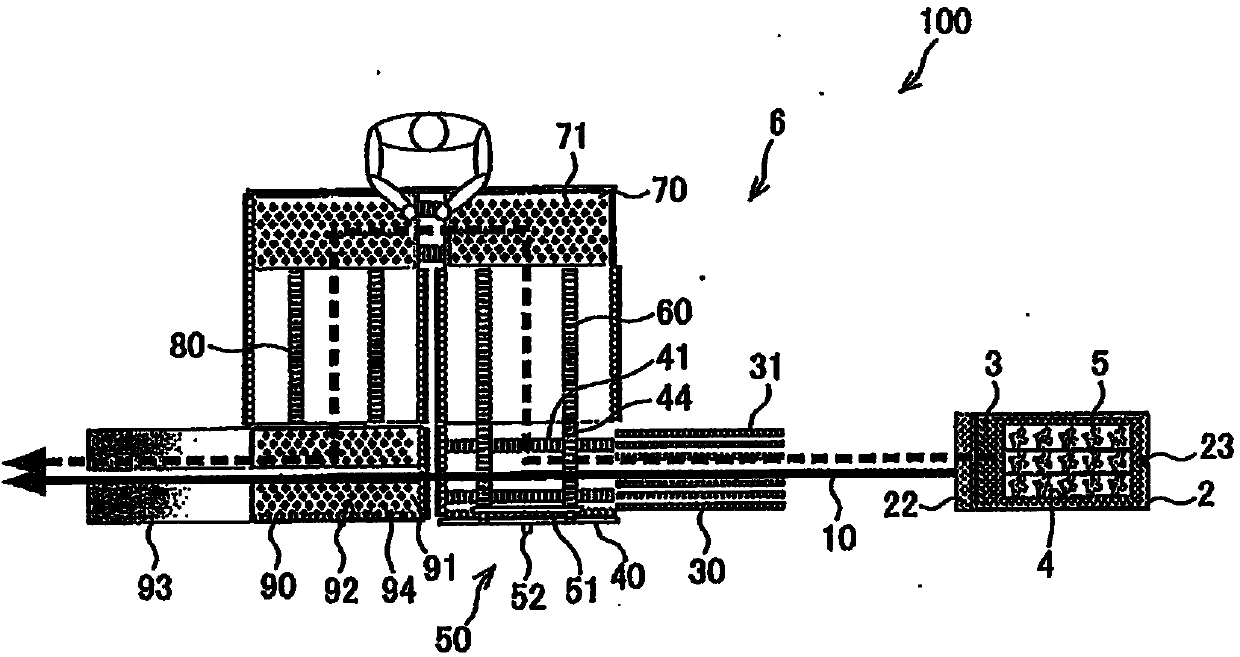

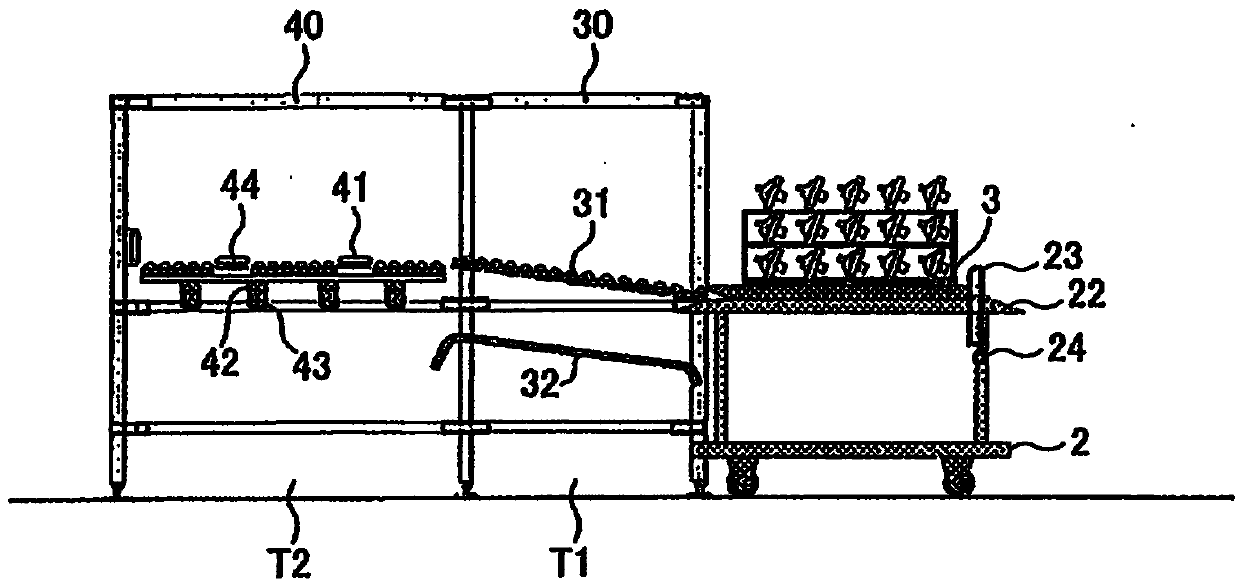

[0040] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0041] figure 1 , figure 2 The overall configuration of the transport system 100 according to the embodiment of the present invention is shown. The transportation system 100 is composed of a plurality of unmanned guided vehicles 2 and a loading and unloading device 6 that transfers pallets 3 to and from the unmanned guided vehicles 2 . In addition, in the following description, in order to understand easily, it assumes that one unmanned guided vehicle 2 is demonstrated.

[0042] (Composition of unmanned guided vehicle 2)

[0043] The unmanned guided vehicle 2 is a vehicle that moves autonomously on a track 10 specified by a magnetic tape, a laser, or the like. The unmanned guided vehicle 2 of the present embodiment is moved by being pulled by a leading vehicle having a power source, but it may be configured to move by itself having a power source such as a motor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com