Eccentric-braking filament feeding device applied to forced internal-external transfer type composite spinning

A composite spinning and feeding device technology, applied in the field of textile processing, can solve the problems of increased energy consumption, low weaving efficiency, poor cohesion, etc., and achieve the effects of simple equipment modification, convenient operation and maintenance, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

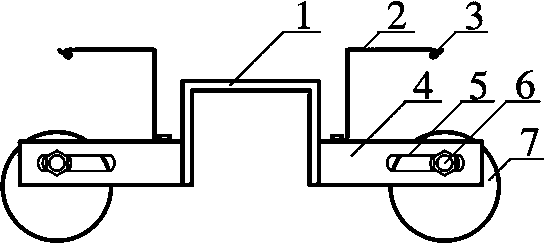

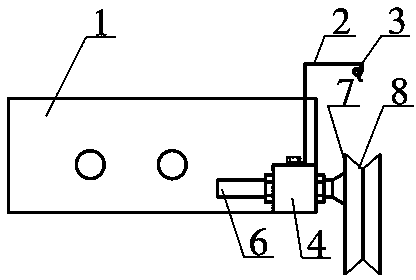

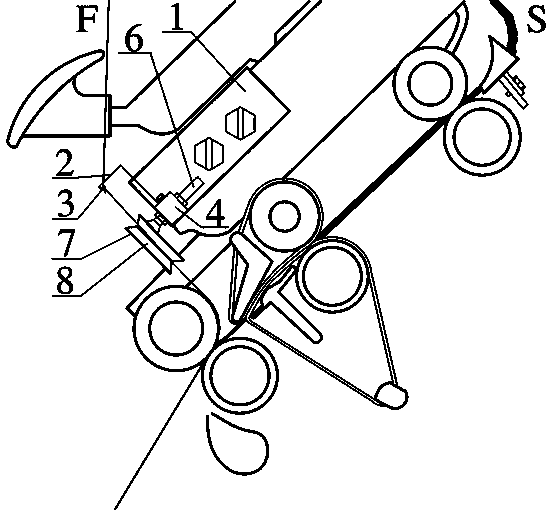

[0012] An eccentric braking filament feeding device for forced internal and external transfer composite spinning according to the present invention will be further described in detail below in conjunction with the accompanying drawings, see the accompanying drawings.

[0013] An eccentric braking filament feeding device for forced internal and external transfer composite spinning is composed of a U-shaped fixed frame 1, a guide wire rod 2, and a wire guide wheel 7, and the U-shaped fixed frame 1 is two parallel and symmetrical The side is perpendicular to the top surface of the U-shaped fixing frame 1, and a pair of threaded fixing holes are symmetrically opened on both sides of the U-shaped fixing frame 1, and the two sides of the U-shaped fixing frame 1 are symmetrically provided with wing plates 4, and the wing plates 4 and the U-shaped fixing frame 1. The side is vertical, and the wing plate 4 is a square plate. The front and rear sides of the wing plate 4 and the top surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com