High performance ECDP hollow FDY filament

A high-performance, hollow technology, used in fabrics, textiles, textiles and papermaking, etc., can solve the problems of poor coloring, hot and dry, and general problems, and achieve good coloring, moisture absorption and perspiration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

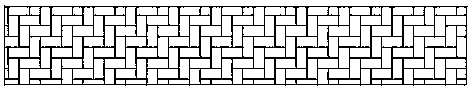

[0011] Described in the present invention is a kind of high-performance ECDP hollow FDY filament, such as figure 1 As shown, the high-performance ECDP hollow FDY filament is woven by warp and weft, the warp is woven by blending ECDP and imported long cotton fiber, and the weft is woven by blending hollow FDY fiber and apocynum fiber The percentages by weight of the components in the warp are 33%-40% for the ECDP, 60%-67% for the imported long cotton fibers, and 60%-67% for the components in the weft. The hollow FDY fiber accounts for 29%-36%, and the apocynum fiber accounts for 64%-71%.

[0012] Further, in the high-performance ECDP hollow FDY filament, the percentage by weight of each componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com