Rack and pinion platform lifting system

A platform lifting, rack-type technology, applied in the field of offshore platforms, can solve the problems of reduced bolt life, hidden dangers, damage, etc., and achieve the effect of extending the service life, avoiding stress, and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

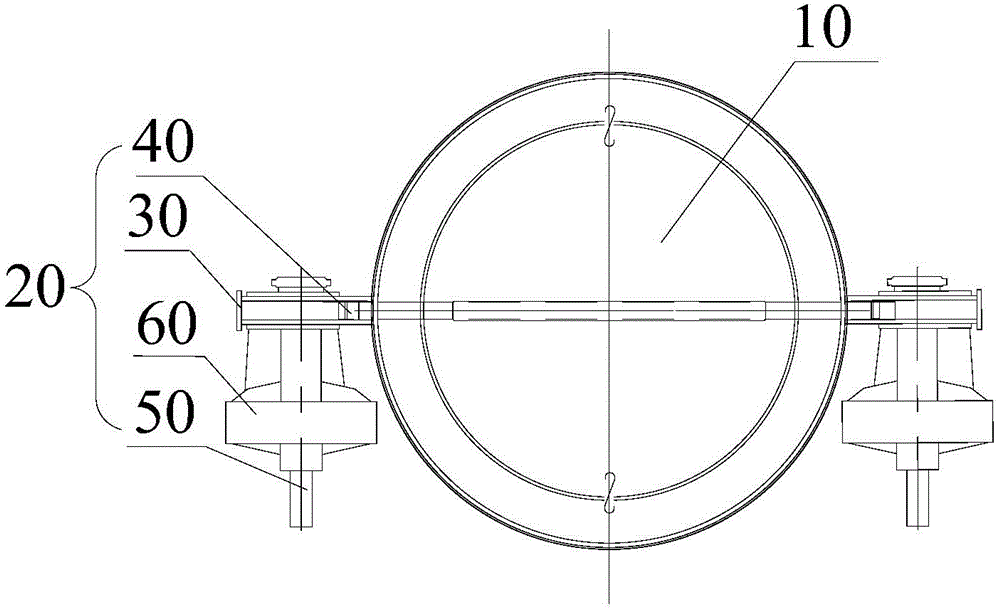

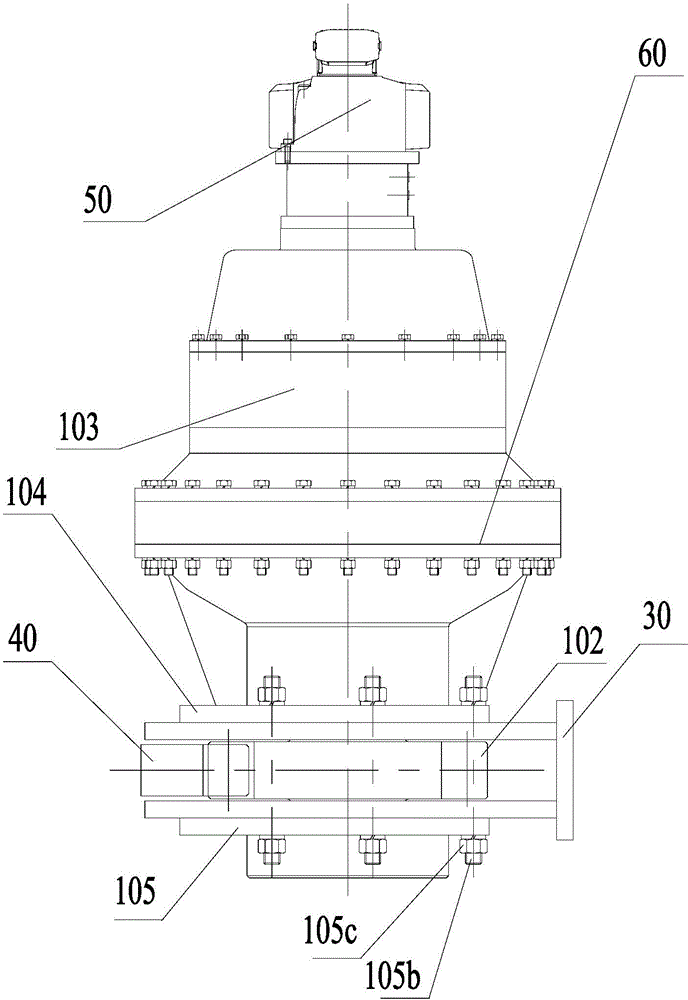

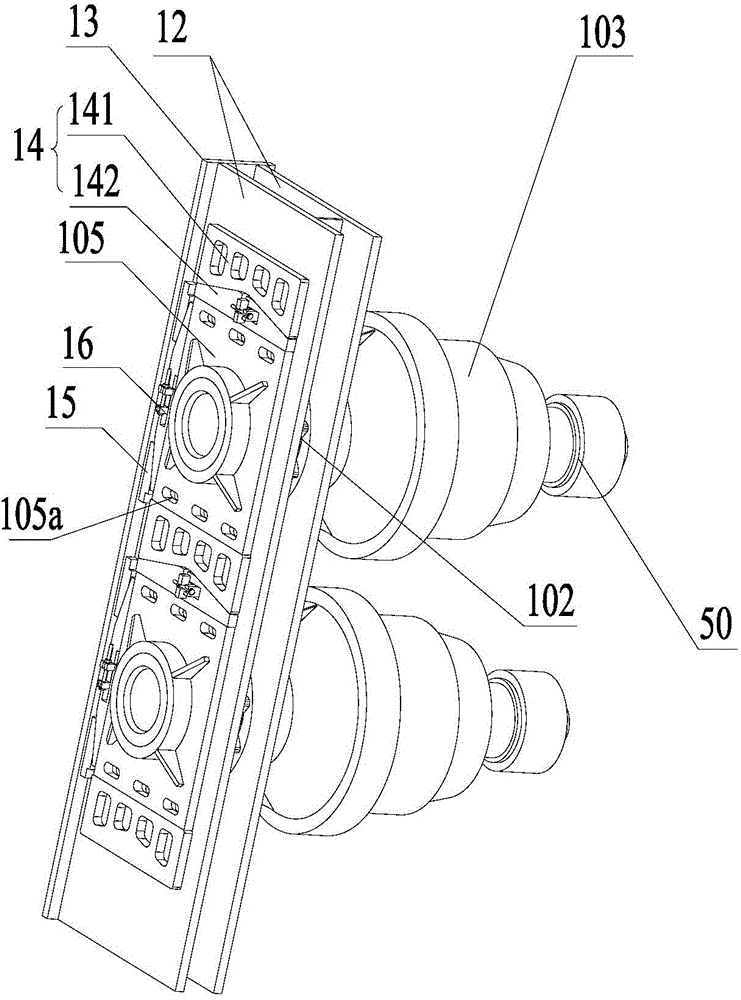

[0035] An embodiment of the present invention provides a rack and pinion platform lifting system, see Figure 1 to Figure 5 , the system includes: a pile frame for being sleeved on the pile leg 10 and a rack and pinion lifting mechanism 20, the rack and pinion lifting mechanism 20 includes a mounting frame 30, a rack 40 fixed on the pile frame, The power unit 50 and the deceleration unit 60 , the deceleration unit 60 is installed on the installation frame 30 and connects the rack 40 and the power unit 50 .

[0036] The reduction device 60 includes: a climbing pinion 102 meshed with the rack 40, a planetary reduction box 103 connected to the power unit 50, a front flange 104 and a rear flange 105, and the front flange 104 and the rear flange 105 are correspondingly provided with Mounting hole 105a, one end of the gear shaft of the climbing pinion 102 passes through the mounting frame 30 and is rotatably connected with the front flange 104, and the other end of the gear shaft pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com