Openable skirt type steel reinforcement cage of reamed pile

A technology of reaming piles and steel cages, applied in sheet pile walls, buildings, foundation structures, etc., can solve problems such as reducing the strength of concrete components, achieve the effects of reducing construction costs, reducing quantity and diameter, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

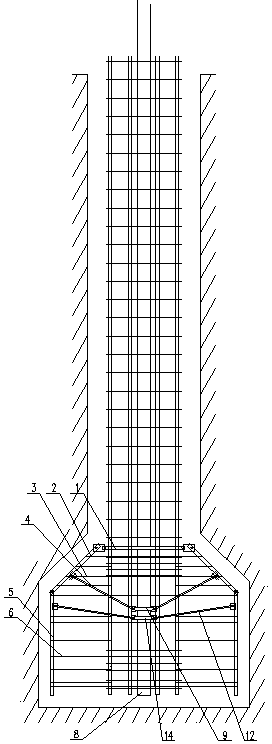

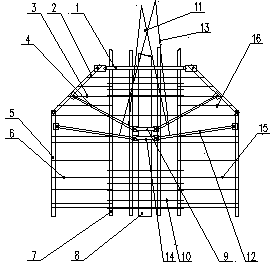

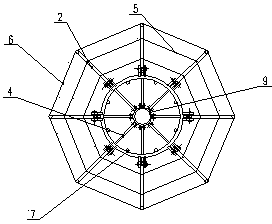

[0022] Such as Figure 1 to Figure 4 Shown is an openable skirt reinforcement cage for reaming piles, which includes steel hoop II10, steel bar III7, and a concrete pipe 8; the steel hoop II10 is evenly arranged around the concrete pipe 8, and each steel hoop II10 is fixedly connected by steel bar III7 The device also includes steel hoop I1, steel bar I2, steel bar II5, connecting rod I4, connecting rod II12, ring I9, ring II14, steel wire rope group I11, steel wire rope group II13, steel strand I3 and steel strand II6; Ⅰ1 is arranged horizontally, and its inner ring is bound and connected with the steel bars Ⅲ7 forming a circle; there are multiple steel bars Ⅰ2, one end of which is evenly hinged on the steel bar hoop Ⅰ1, and the other end is hinged with one end of steel bar Ⅱ5; the middle part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com