Hollow Outer Rotor Air Motor

An air motor and outer rotor technology, applied in the directions of engine components, machines/engines, blade support components, etc., can solve the problem that the inner rotor air motor is not suitable for work, etc., to solve the problem of filtrate shunt, easy to manufacture, simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

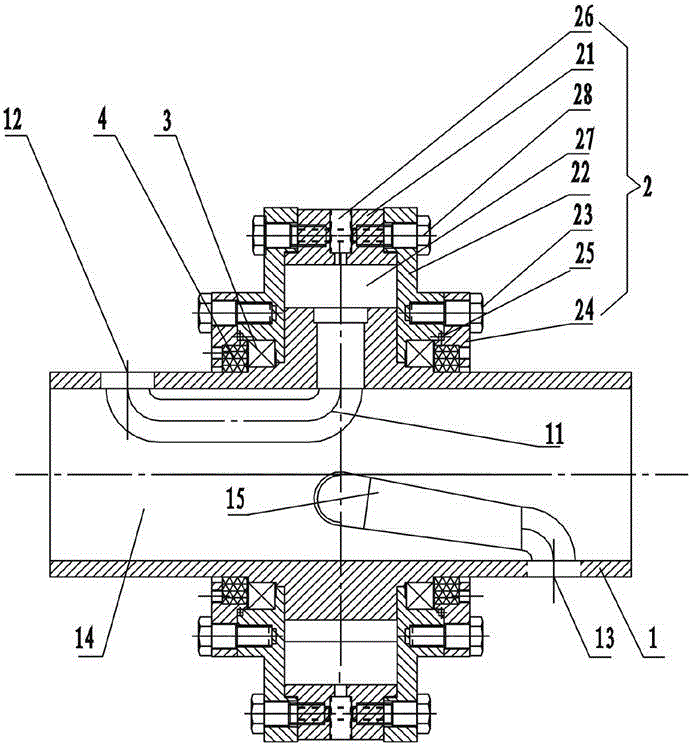

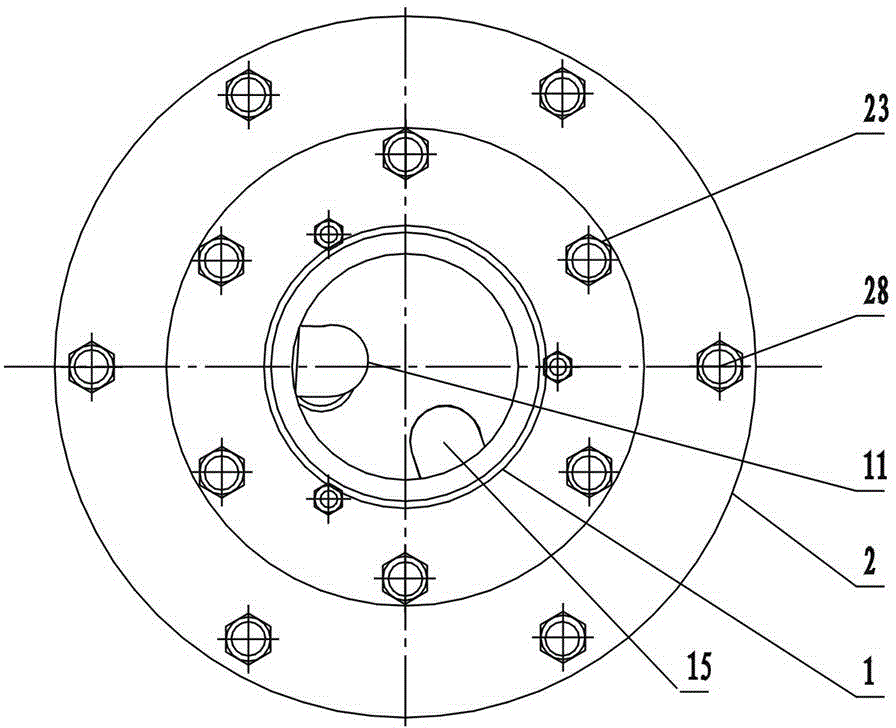

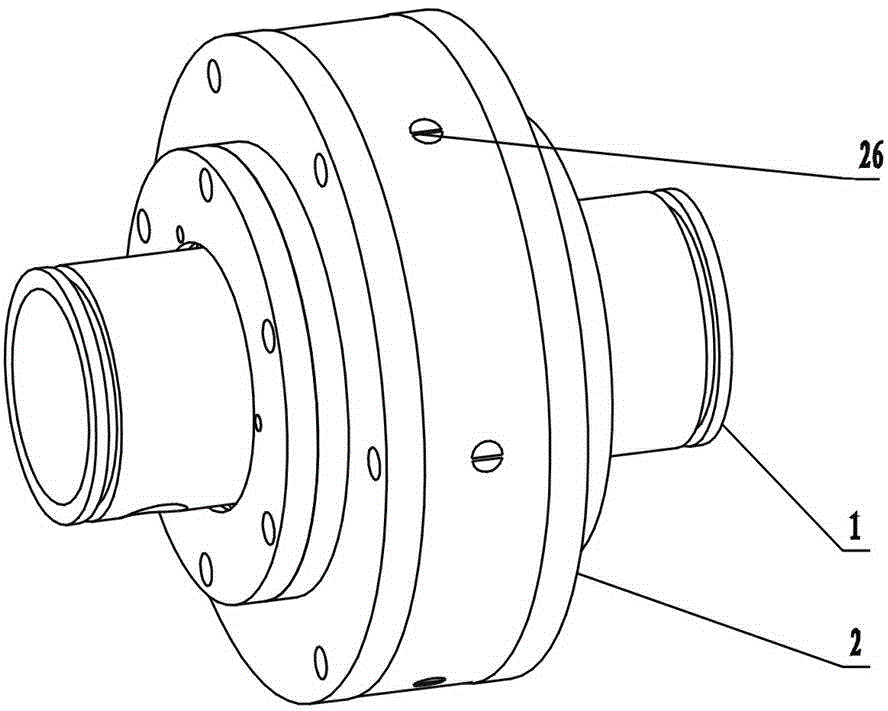

[0032] The present invention will be further described below in conjunction with each accompanying drawing.

[0033] Referring to the accompanying drawings, the hollow outer rotor air motor of the present invention includes a fixed shaft 1 and a rotor 2 coaxially sleeved outside the fixed shaft 1, and the rotor 2 further includes a rotor body 21, blades 29, spring members 26, bearings The seat cover 22 and the end cover 24, the blades 29 are embedded in the blade grooves 211 in the rotor main body 21 in a radially movable manner; the spring members 26 have the same number as the blades 29, and the compression springs are installed in the inner cavity 2621 of the spring sleeve 262, and the springs The sleeve 262 is movably installed in the inner cavity 2611 of the spring pressing rod 261, the spring pressing rod 261 is fixed on the rotor main body 21, and each spring sleeve 262 abuts against the outer surface of each blade 29; two bearing seat covers 22 are respectively fixed A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com