Assembly device with sealing effect

A technology for assembling devices and gaskets, which is applied in the direction of liquid variable displacement machinery, variable displacement pump components, connecting components, etc., can solve problems affecting the life of parts, leakage channels, unfavorable sealing, etc., and achieve reduced processing accuracy and good sealing Effect, leakage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to help those skilled in the art to accurately understand the claimed subject matter of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

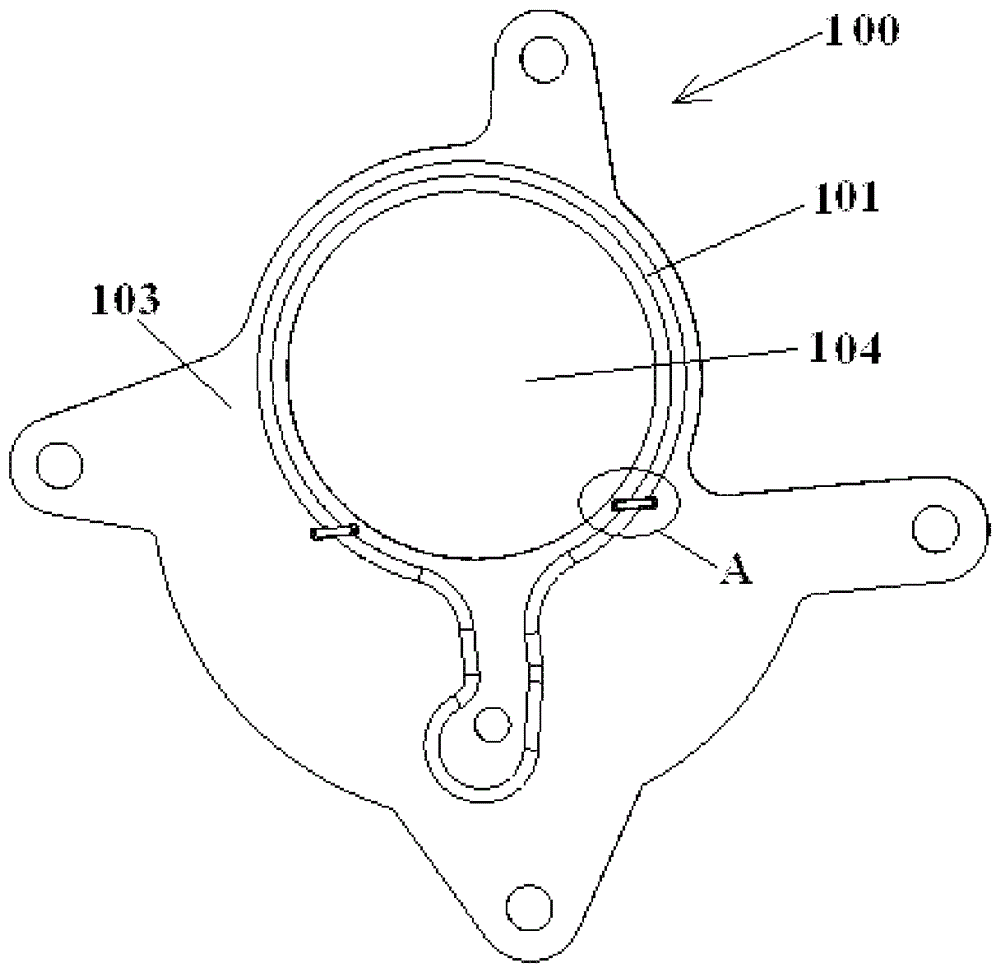

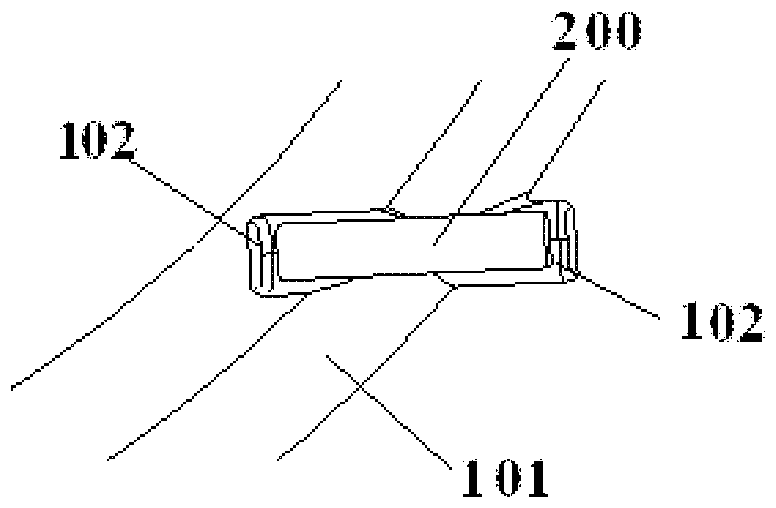

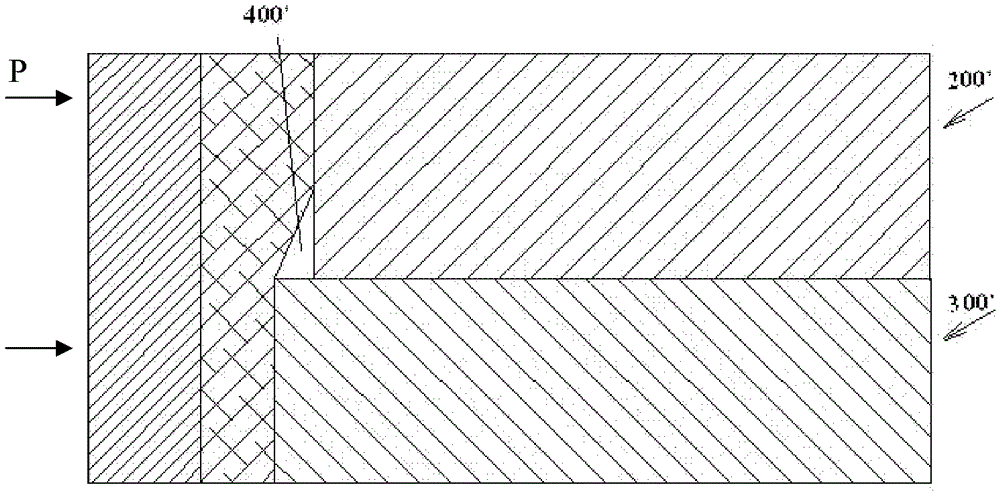

[0033] In order to solve the sealing problem of this special structure without affecting the assembly cycle, a special gasket with the following structure is designed. At the position of the three-joint surface corresponding to the gasket, the rib form increases the rubber groove structure, and under the condition of not weakening the sealing effect of the convex rib, an elastic body is pre-filled in the rubber groove (the elastic body is generally a rubber material, which can be vulcanized. Or bonding form to combine the elastomer with the gasket) to make up for the height difference caused by the flange surface. When the flange surface compresses the gasket, the elastomer will be squeezed to completely fill th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com