An automatic scanning device for ultrasonic testing

A scanning device and ultrasonic testing technology, used in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve problems such as high work intensity, unstable data, and inability to fit various styles of welds. , to achieve the effect of convenient operation, reasonable structure and layout, stable and reliable scanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

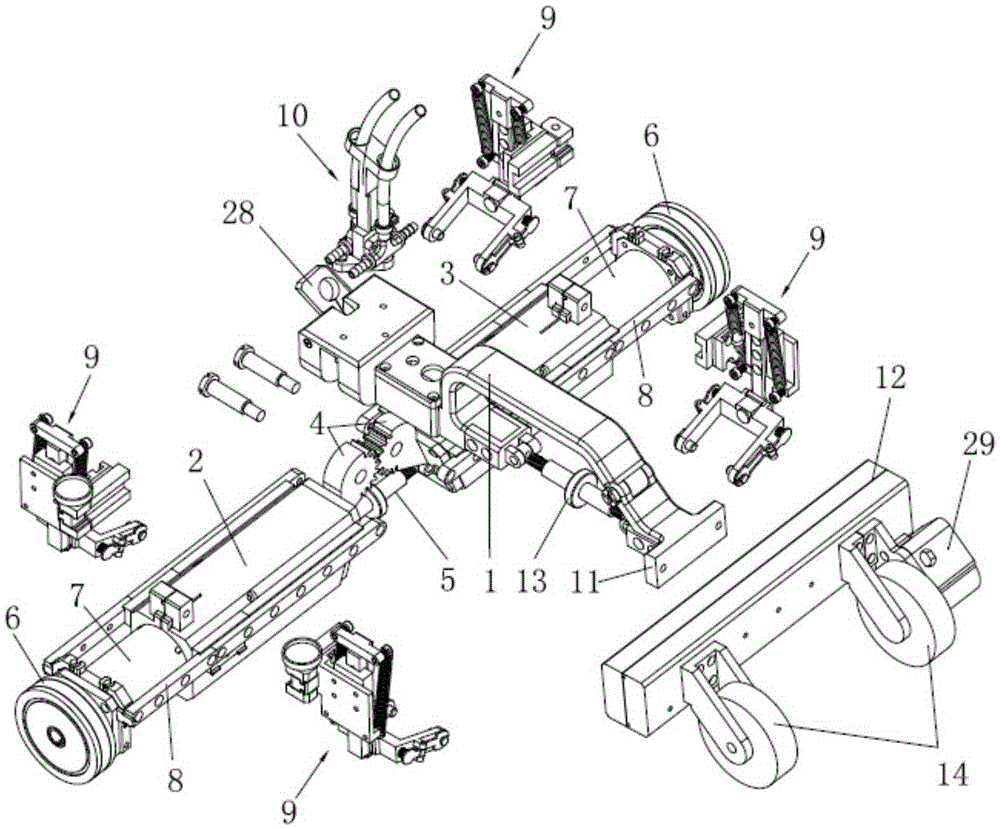

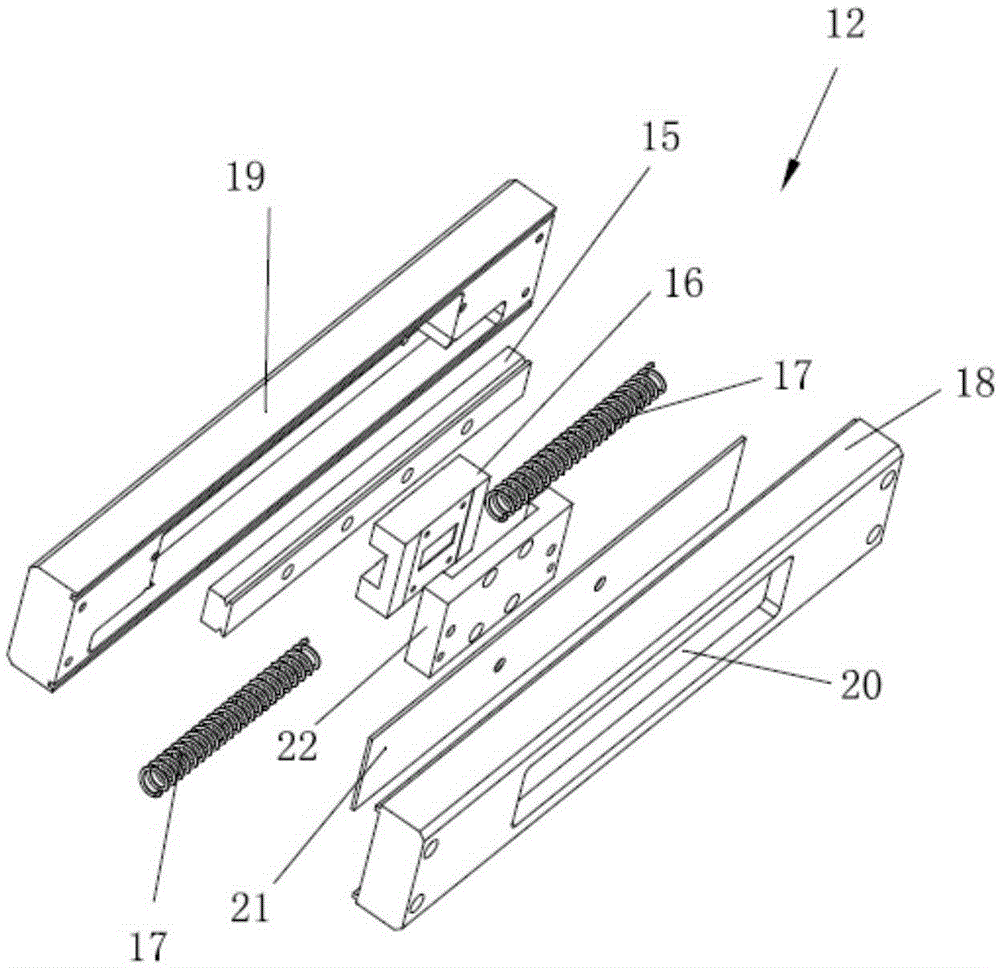

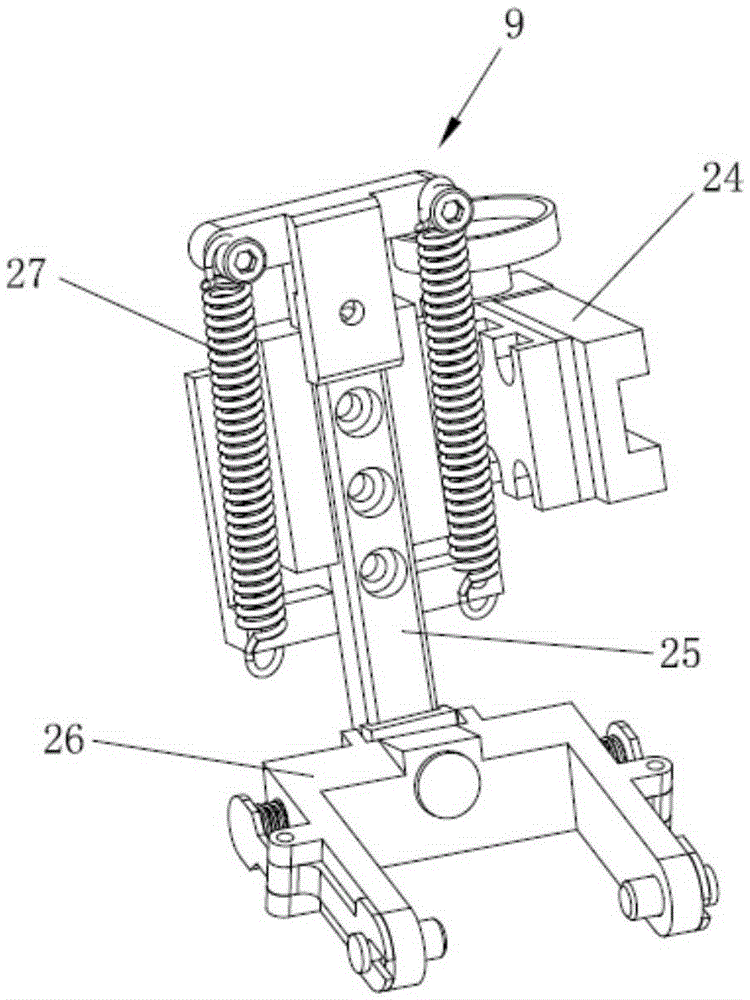

[0028] Attached below figure 1 to attach Figure 4 The technical solutions of the present invention are further described through specific implementation methods.

[0029] An automatic scanning device for ultrasonic detection, comprising a handle assembly 1 and a left scanning arm 2 and a right scanning arm 3 respectively symmetrically arranged at one end of the handle assembly 1, the left scanning arm 2 and the right scanning arm One end of the scanning arm 3 is respectively provided with mutually meshing gears 4, and the bottom of the gear 4 is provided with a first adjustment screw 5 for adjusting the left scanning arm 2 and the right scanning arm 3 to turn up or down. The other ends of the scanning arm 2 and the right scanning arm 3 are respectively provided with first magnetic wheels 6 for ensuring the magnetic attraction force when the automatic scanning device is turned upside down or scanned vertically. The motors 7 on the left scanning arm 2 and the right scanning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com