Opposite electronic component working equipment

A technology of electronic components and operating equipment, which is applied in the field of opposed electronic component operating equipment, can solve the problems of reducing test operation production efficiency, heavy workload, and test port standby, etc., and achieves the effect of easy expansion of operating area and reduction of table space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make your examiner further understand the present invention, hereby give a preferred embodiment and cooperate with the drawings, as follows in detail:

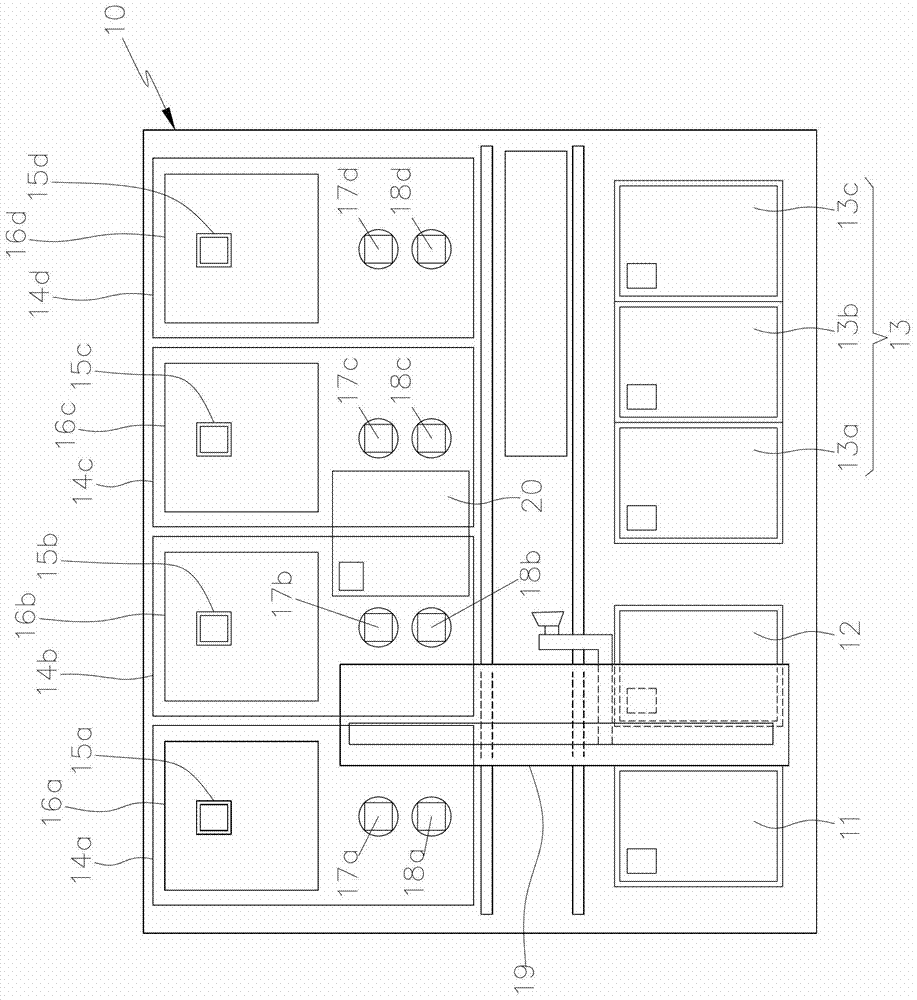

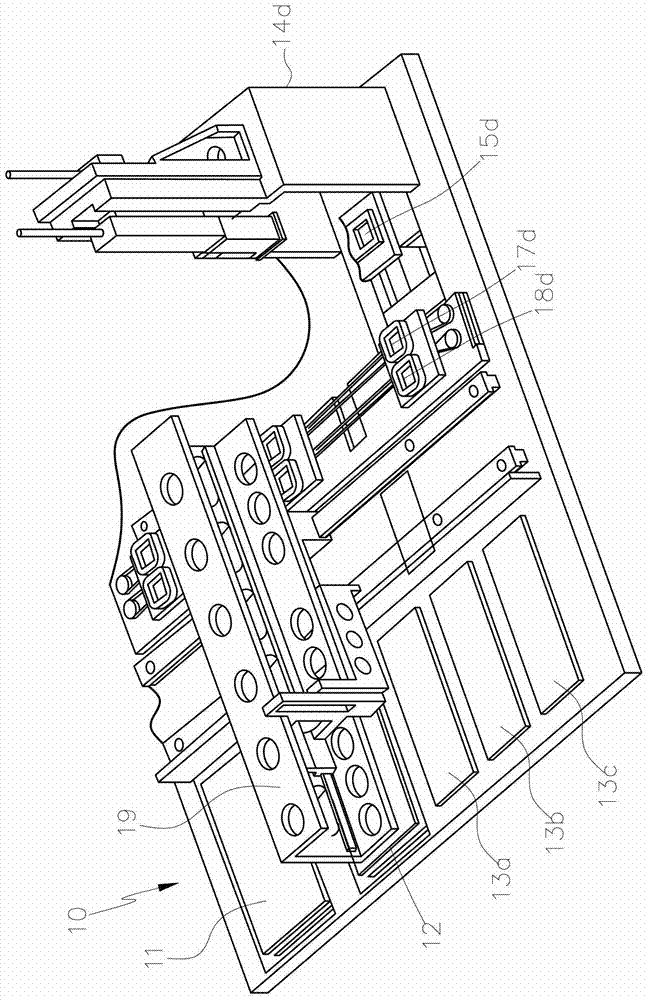

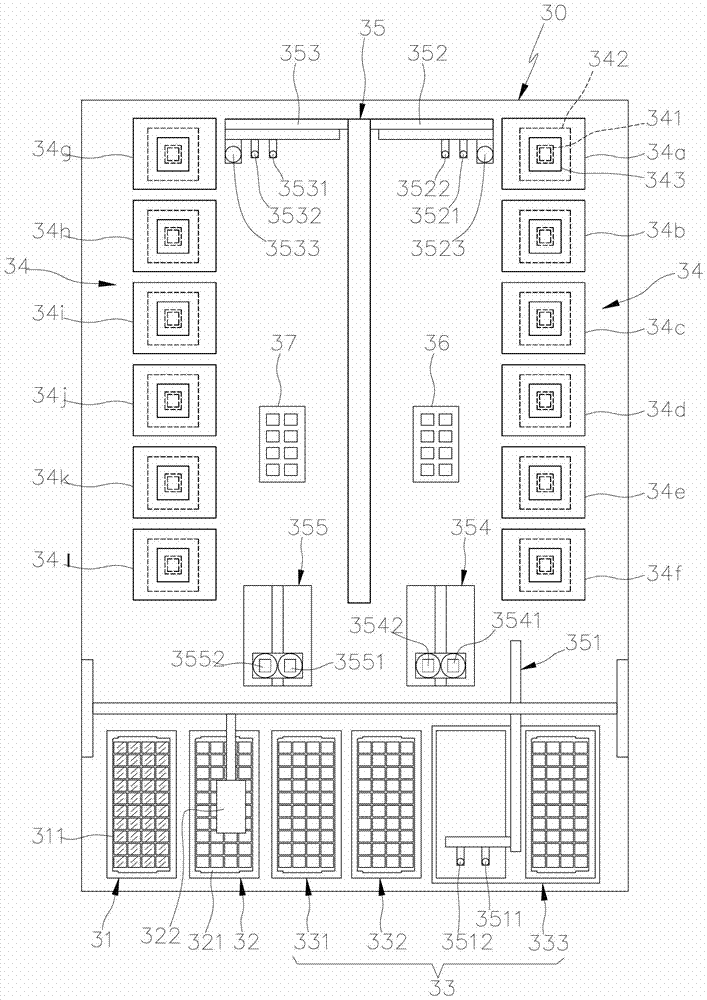

[0040] see image 3 , the opposed type electronic assembly operation equipment of the present invention, which is equipped with a feeding device 31, an empty tray device 32, a material receiving device 33, an operating device 34, and a conveying device 35 on the machine table 30, and is used to control and integrate the actions of each device to A central control unit (not shown in the drawings) for performing automated operations; the feeding device 31 can lift and carry a plurality of trays 311, and each tray 311 can accommodate at least one electronic component to be executed. The empty tray device 32 Can lift and carry a plurality of empty trays 321, and use a tray shifter 322 to transfer the empty trays of the feeding device 31 to the empty tray device 32, or transfer the empty trays on the empty tray d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com