Control method of vehicle battery cooling system

A cooling system and battery technology, which is applied in the combined arrangement of batteries and power plants, secondary batteries, etc., can solve the problems of low work efficiency, achieve the effects of reducing working time, ensuring cooling rate, and increasing cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments. It should be noted that each structure in the drawings is only schematic and not restrictive, so that those of ordinary skill in the art can best understand the principle of the present invention, and they are not necessarily drawn to scale.

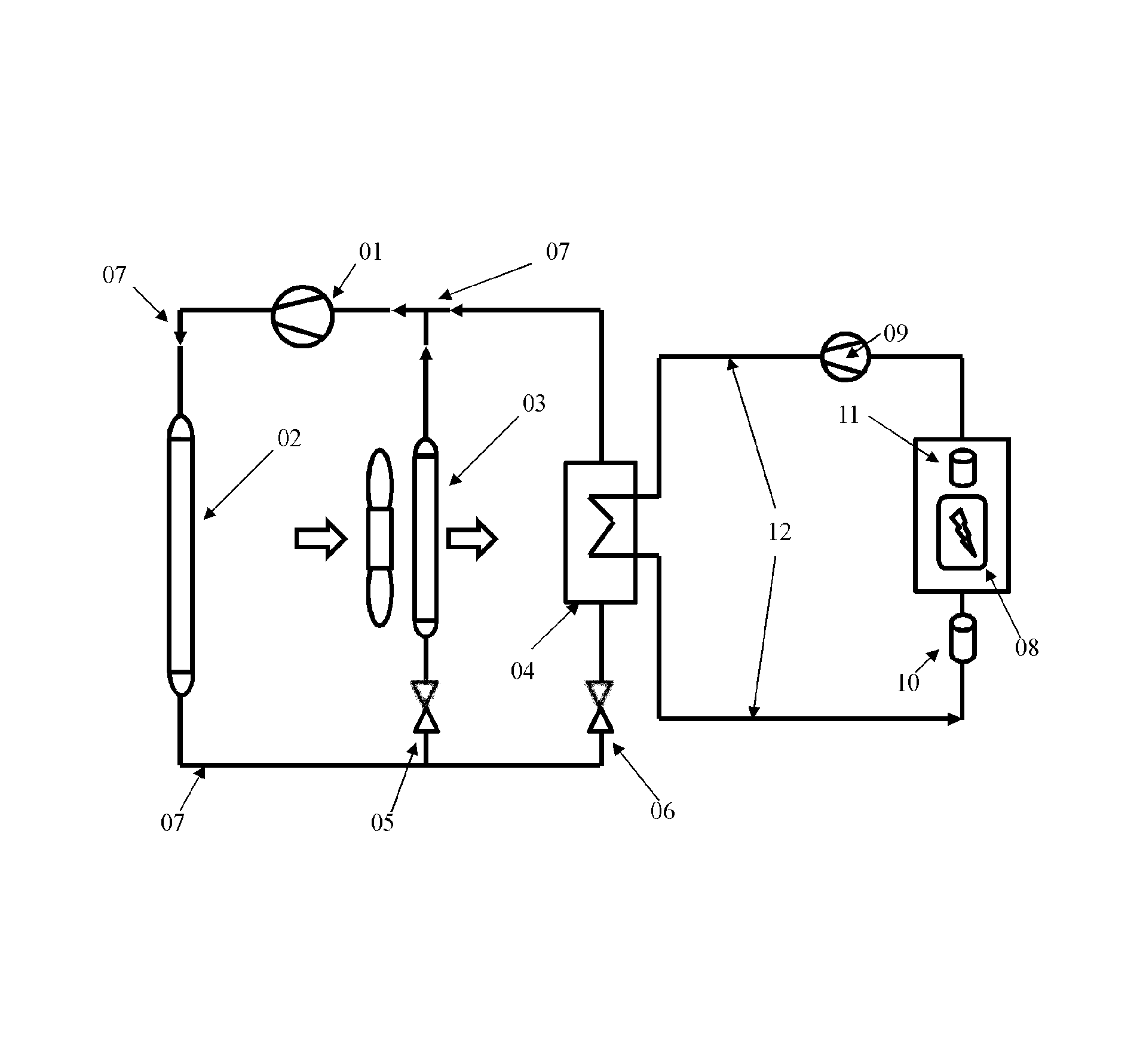

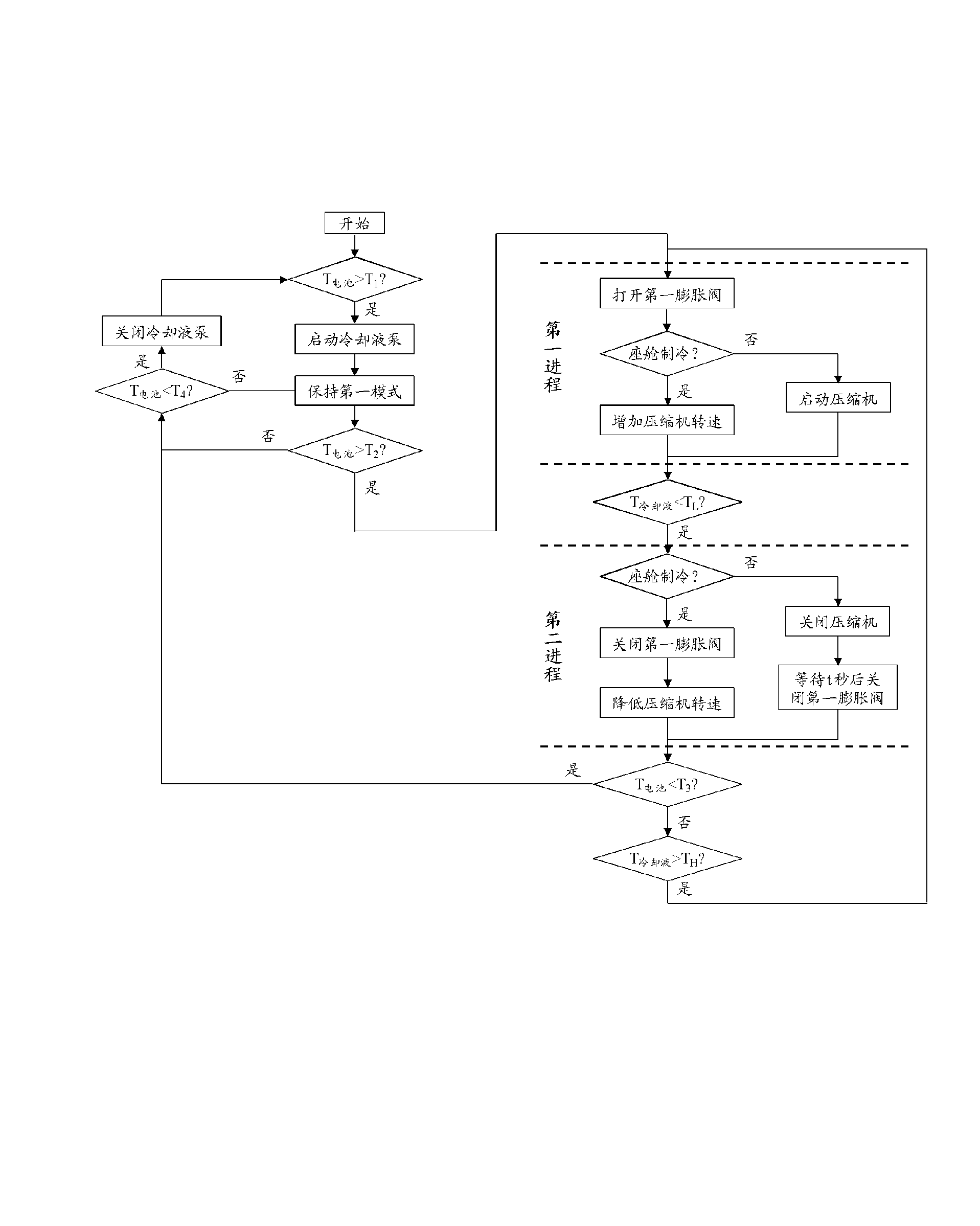

[0027] figure 1 An example vehicle battery cooling system suitable for the method provided by the present invention is shown. Such as figure 1 As shown on the right, the battery cooling system of the electric vehicle to which the present invention is applied may generally include a battery 08, a coolant pump 09, a coolant pipeline 12, a battery cooler 04, a first expansion valve 06, and an electric compressor 01 Among them, the electric compressor 01 is also used in the air condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com