Wire harness corner support

A corner and wire harness technology, applied in the field of auto parts, can solve the problems of easy wear and tear, and the bending angle affects the performance of the wire, and achieves the effect of preventing wear, not easy to mess up the wire, and ensuring the positioning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

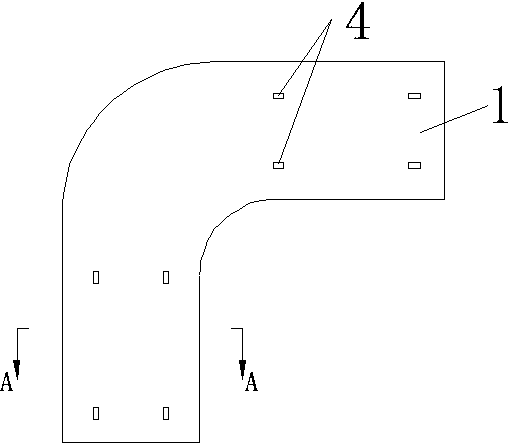

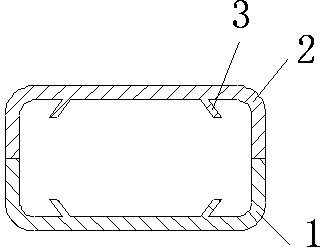

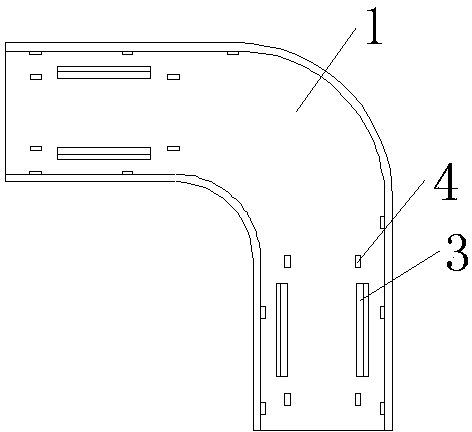

[0014] As shown in the figure, the wire harness corner bracket of the present invention includes a bracket upper cover 1 and a bracket lower cover 2, the bracket upper cover 1 and the bracket lower cover 2 are L-shaped that are mutually adapted, and the bracket upper cover 1 and The bracket lower cover 2 is hollow after interlocking, and a pair of strip-shaped bosses 3 are respectively arranged on two straight sides of the inner surface of the bracket upper cover 1, and each pair of strip-shaped bosses 3 is symmetrical. The positions corresponding to the two straight edge sections of the inner surface of the lower cover 2 of the bracket are also respectively provided with corresponding strip bosses 3, wherein each pair of the strip bosses 3 has a figure-eight cross-section. The cover 1 is provided with multiple pairs of holes 4 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com