Light rail vehicle converter cabinet

A technology for converter cabinets and vehicles, which is applied in the direction of casing/cabinet/drawer parts, output power conversion devices, electrical components, etc. problems, to achieve the effect of good processing technology, improve connection strength, and reduce the difficulty of welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

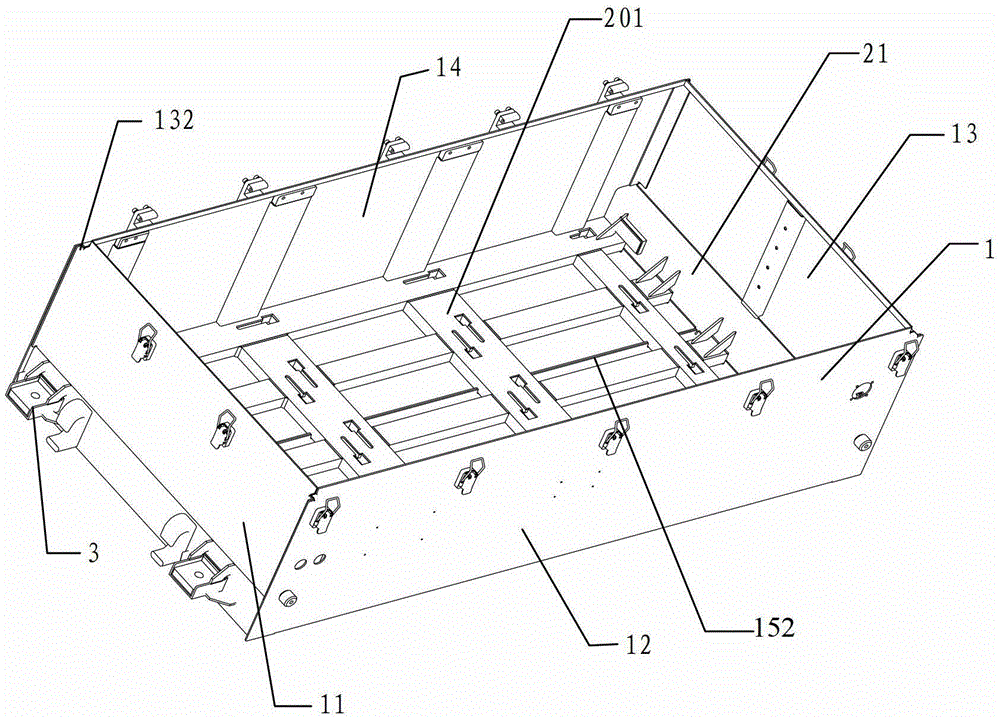

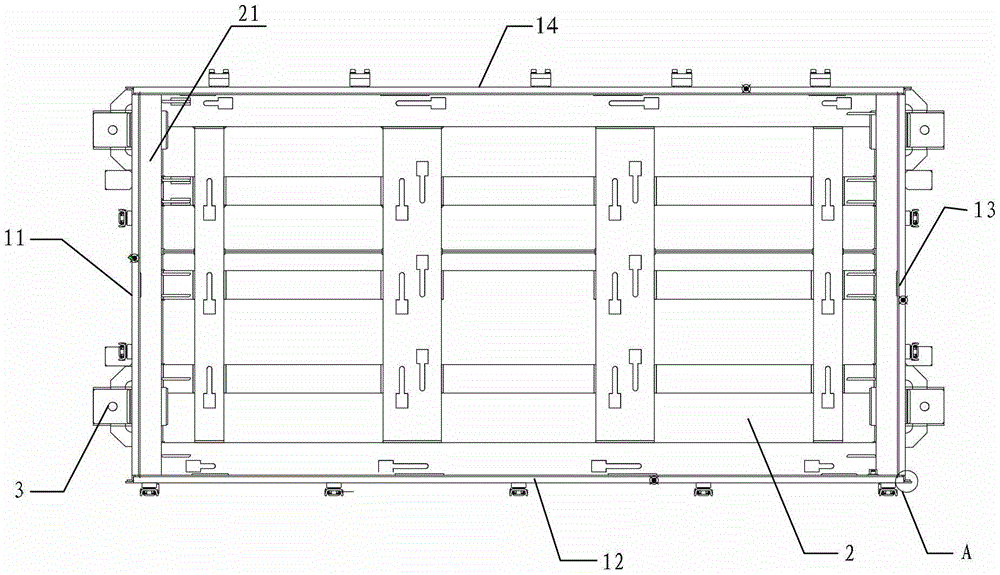

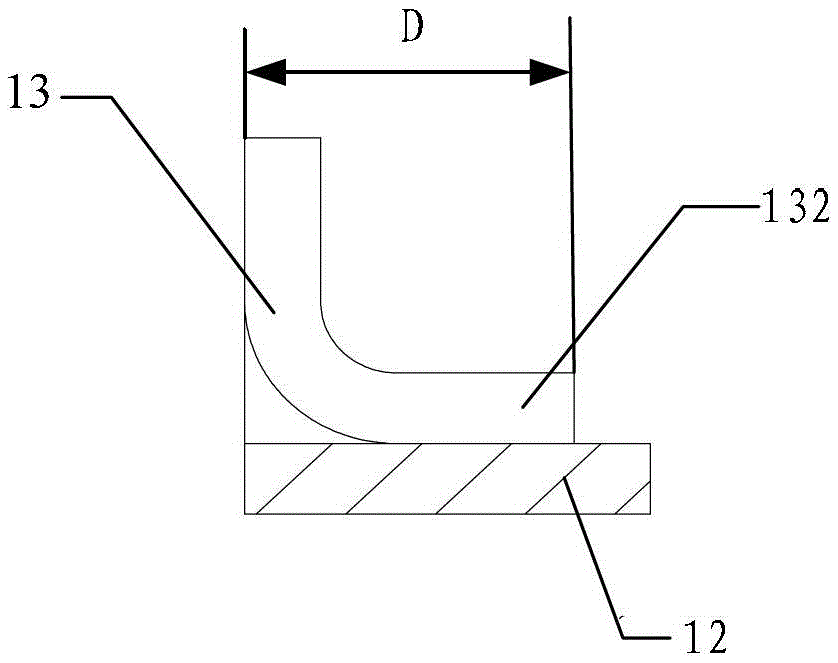

[0015] figure 1 It is a perspective view of an embodiment of a light rail vehicle converter cabinet of the present invention; figure 2 for figure 1 top view of Figure 4 for figure 1 Schematic diagram of the installation structure of the middle lifting lug; Figure 5 for Figure 4 view from the other direction; please refer to figure 1 , figure 2 , Figure 4 and Figure 5 , this embodiment provides a light rail vehicle converter cabinet, including: a bottom plate 2, a side wall plate 1 fixedly arranged on the bottom plate 2, and at least two lifting lugs 3, the bottom plate 2 and the side wall plate 1 are enclosed for The accommodating cavity for accommodating converter devices; the bottom plate 2 includes a mounting transition portion 21 formed on the edge of the top surface of the bottom plate, and at least two connecting through holes 22 are opened on the mounting transition portion 21, and the tail ends of the lifting ears 3 pass through the connecting through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com