Flexographic printing mechanism with toggle system

A technology of flexographic printing and printing mechanism, which is applied in printing presses, rotary printing presses, rotary printing presses, etc., and can solve problems such as printing image interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

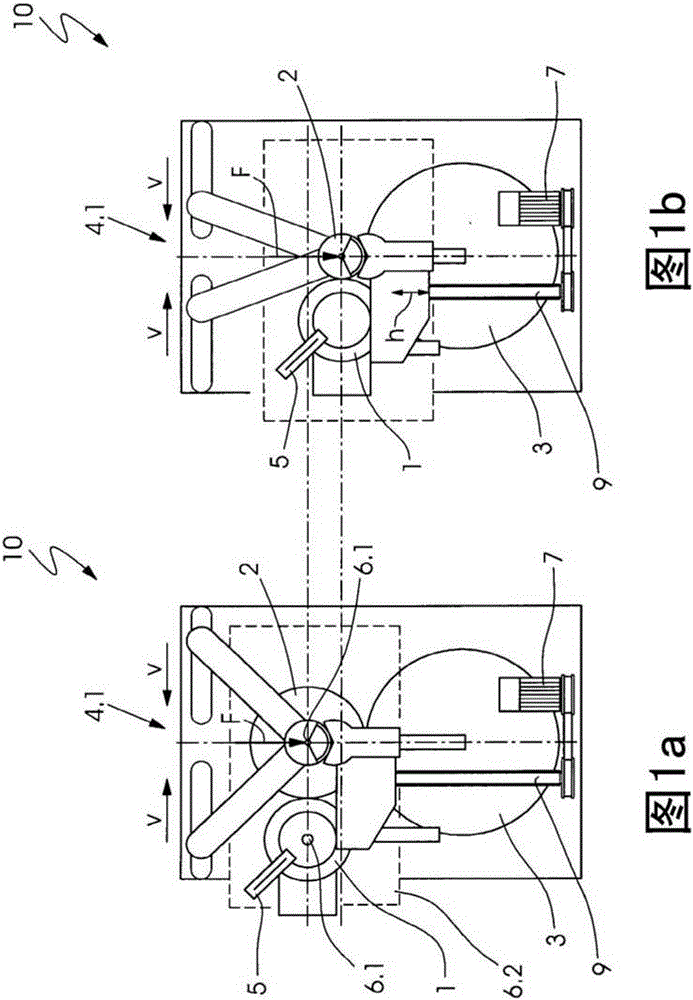

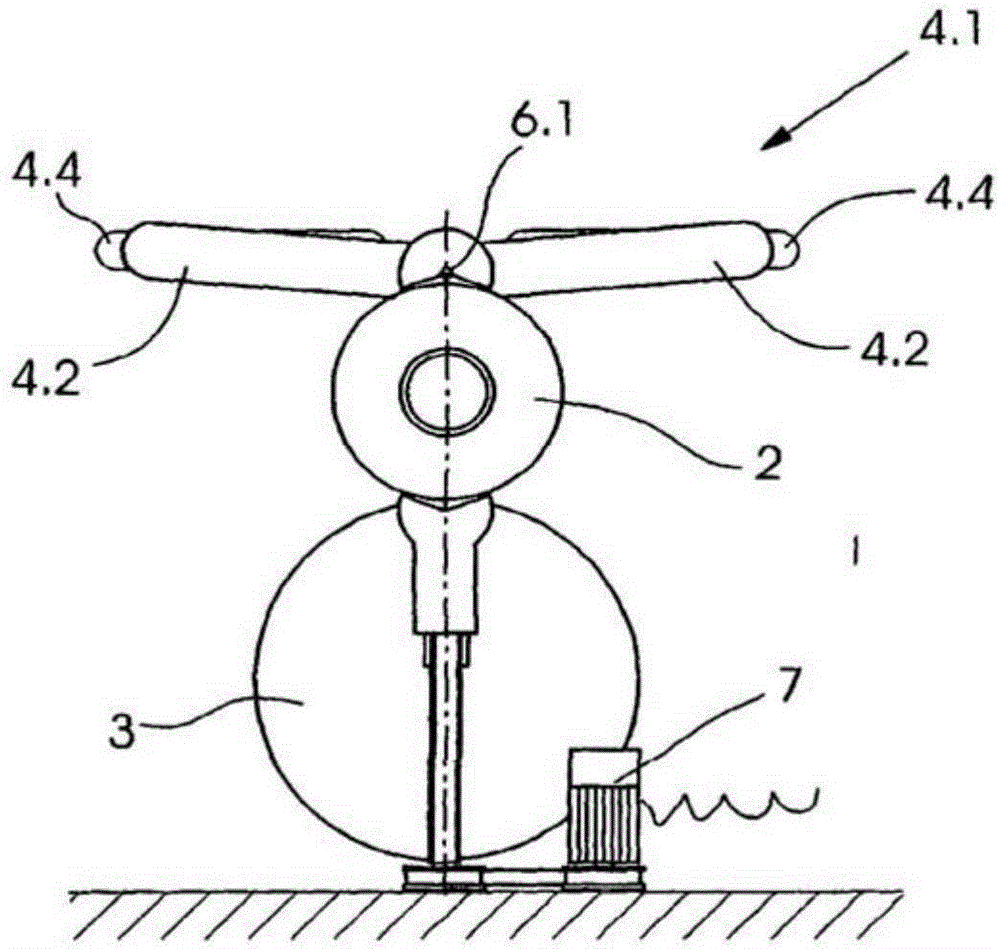

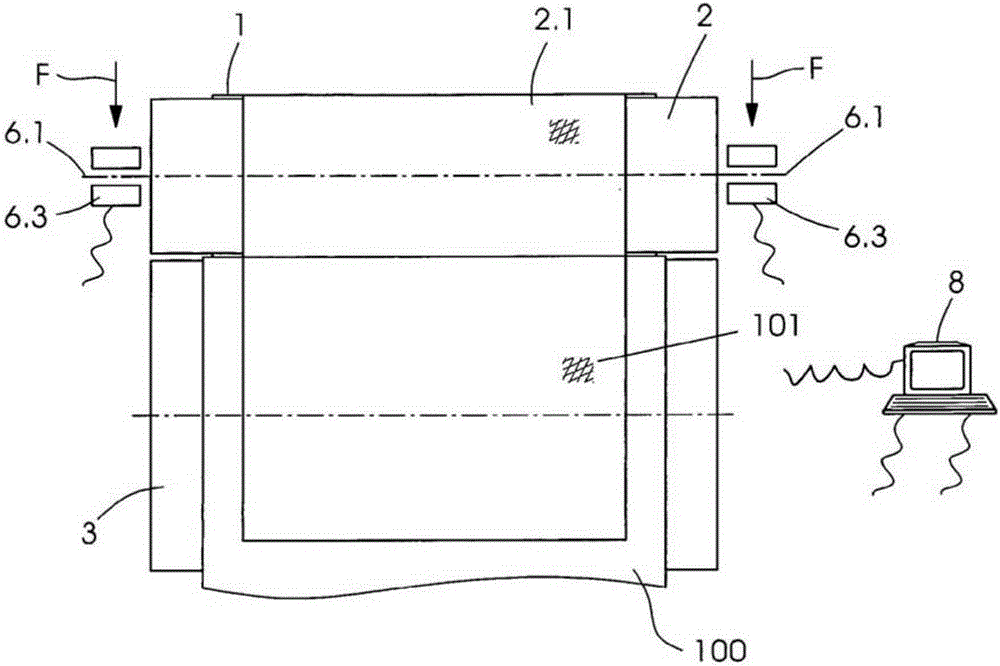

[0026] FIG. 1 shows a printing unit 10 according to the invention, which is embodied as a flexographic printing unit. The printing unit 10 has a printing form cylinder 2 , an anilox roller 1 and a counterpressure cylinder 3 . A doctor blade 5 is installed on the anilox roll 1 . The anilox roller 1 and the printing plate cylinder 2 have a bearing 6.1 which is arranged on a common bearing plate 6.2. Mounted on the bearing 6 . 1 of the printing plate cylinder 2 is a toggle linkage system 4 . 1 which exerts a prestressing force F on the bearing 6 . 1 and thus onto the printing cylinder 2 . The carrier plate 6.2 is assigned a servo drive 7, wherein the movement of the servo drive 7 is transmitted via the spindle 9 to the carrier plate 6.2. It is thereby possible to slide the position of the bearing plate 6 . Figure 1a A plate cylinder 2 of larger diameter is shown in , while Figure 1b A plate cylinder 2 of smaller diameter is shown. In order to form a further printing gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com