Straw picking and crushing machine Covering compound operation machine after sowing

A technology of pulverizers and operating machines, applied in agricultural machinery and tools, agriculture, harvesters, etc., can solve the problems of high production cost and operating cost, affecting the effect of straw returning to the field, and straw is easily affected by wind, so as to reduce the Labor intensity and production cost, reducing soil compaction and plowing times, and achieving the effect of conservation tillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

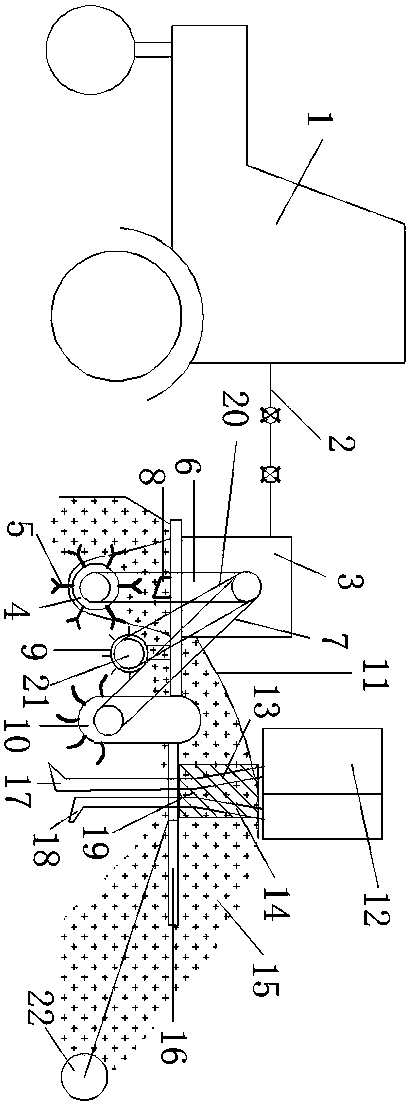

[0016] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

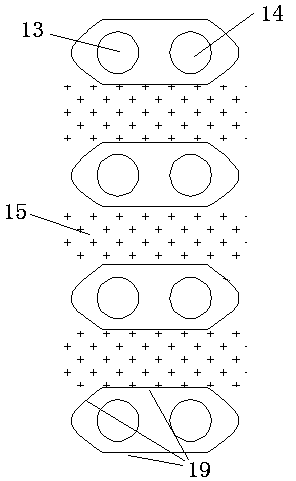

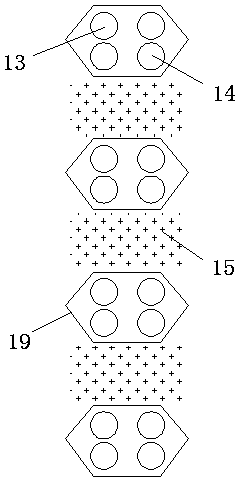

[0017] Such as figure 1 As shown, due to size constraints, it is possible to put figure 1 It is more intuitive to rotate counterclockwise by 90°. The overall structure diagram of the straw picking and pulverizing machine covered after sowing, including the reverse rotation straw picking and crushing device, the conveying and throwing device and the rotary tillage and fertilization device connected in sequence, and the reverse rotation straw picking The crushing device, the conveying and spreading device and the rotary tillage, seeding and fertilizing device are integrated machines, and the rotary tillage, seeding and fertilizing device includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com