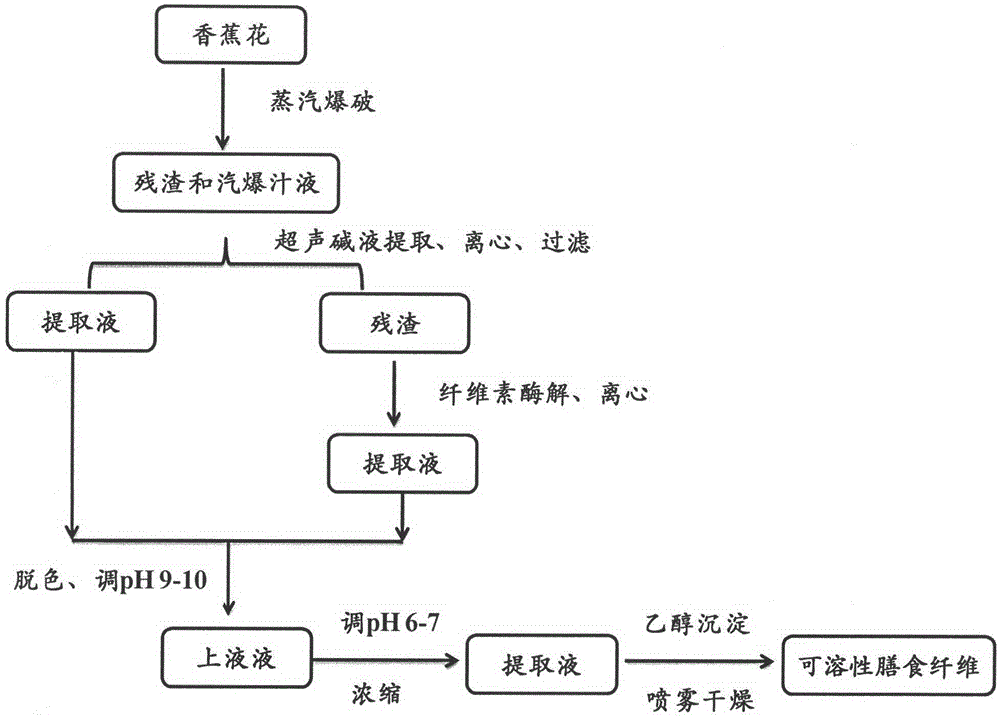

The preparation method of banana flower soluble dietary fiber

A technology for dietary fiber and banana flower, which is applied in the processing field of banana flower soluble dietary fiber, can solve problems such as shortening the modification time of SDF, and achieve the effect of high purity, good quality and inhibiting α-glucosidase activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Choose freshly picked banana flowers, remove the outer flakes and flowers, then chop them to 5cm, put 100g of the sample into the steam explosion tank of the 400ml steam explosion test bench, and release it instantly after 90s under the pressure of 1.5MPa (Release speed 0.00875s), collect juice and residue. Add 2 times the volume of 1% NaOH solution to the collected materials, ultrasonic treatment for 10 minutes, power of 70W, put the extract in a centrifuge, centrifuge for 10 minutes, 5000r / min, and then filter. Add 5% cellulase to the filtered residue, react for 2h at 35°C, pH5, add an equal volume of 1% NaOH solution, sonicate for 5min, power 70W, put the extract in a centrifuge Centrifuge for 10min, 5000r / min, and then filter. The combined filtrates were added with 30ml of 30% H 2 O 2 , Placed at room temperature for 48h. The decolorized liquid was centrifuged, filtered, and adjusted to pH 9, and after standing for 3 hours, it was filtered again. The pH value of t...

Embodiment 2

[0024] Choose freshly picked banana flowers, remove the outer flakes and flowers, then chop them to 5cm, put 100g of the sample into the steam explosion tank of the 400ml steam explosion test bench, and release it instantly after 90s under the pressure of 2.0MPa (Release speed 0.00875s), collect juice and residue. Add 2 times the volume of 1% NaOH solution to the collected materials, ultrasonic treatment for 20min, power of 150W, put the extract in a centrifuge, centrifuge for 10min, 5000r / min, and then filter. Add 5% cellulase to the filtered residue, react for 2h at 35°C, pH5, add an equal volume of 1% NaOH solution, sonicate for 10min, power 150W, put the extract in a centrifuge Centrifuge for 10min, 5000r / min, and then filter. The combined filtrates were added with 30ml of 30% H 2 O 2 , Placed at room temperature for 48h. The decolorized liquid was centrifuged, filtered, and adjusted to pH 9, and after standing for 3 hours, it was filtered again. The pH value of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com