Device and method for collecting and guiding free particles during conveying of rod-shaped products for tobacco industry

A product, rod-shaped technology, applied in the field of devices, can solve the problems of complexity, large structure space, high operating cost, etc., and achieve the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

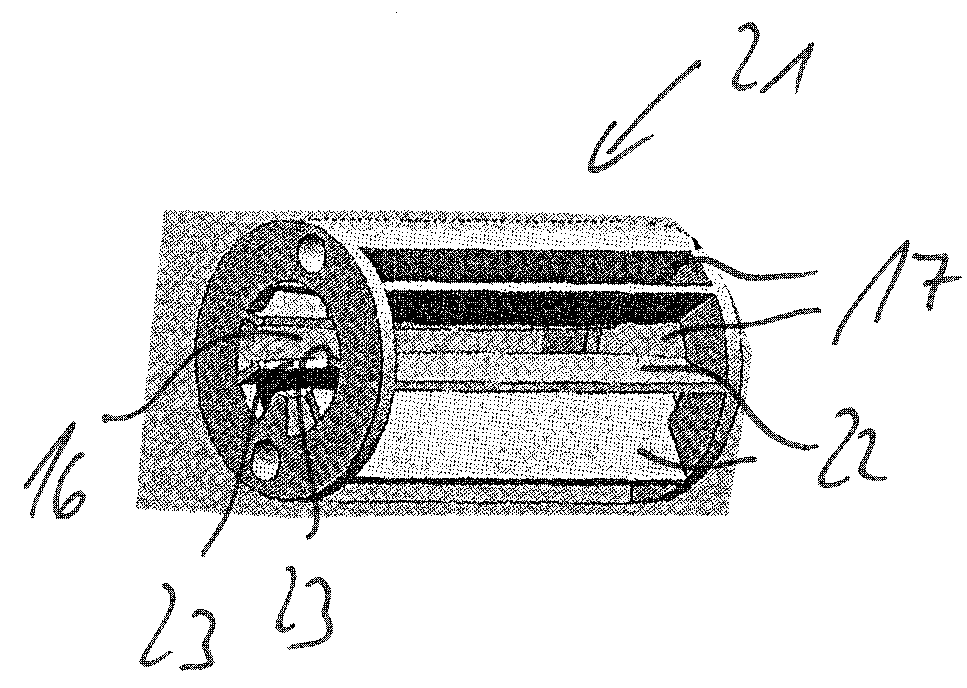

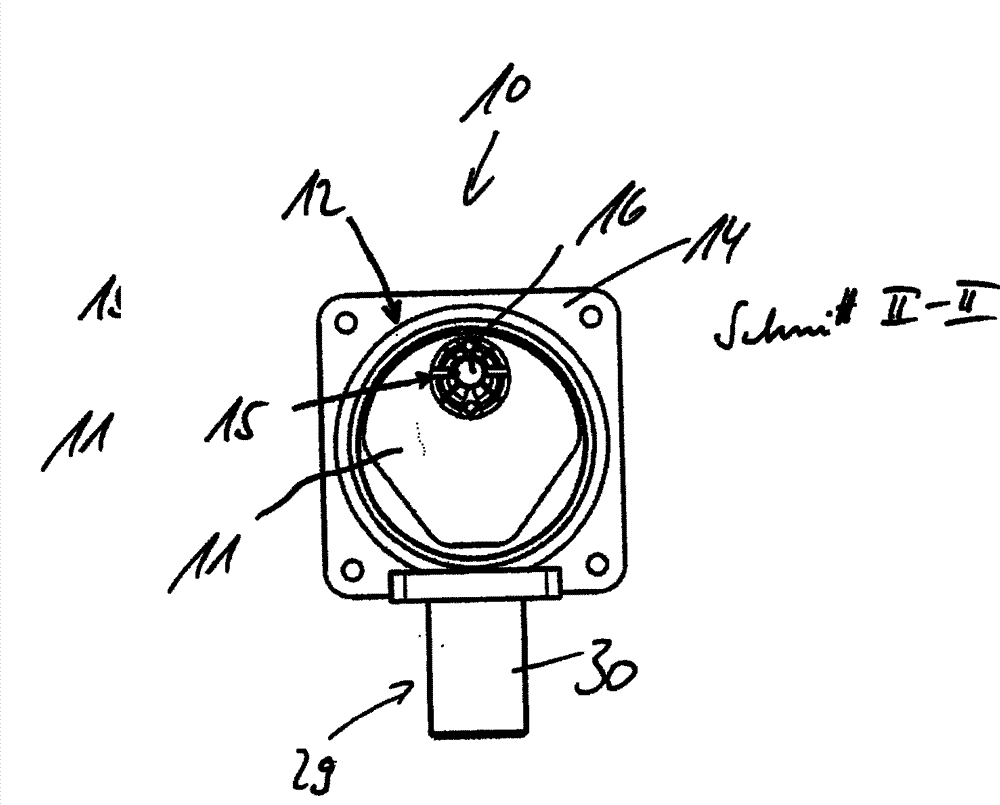

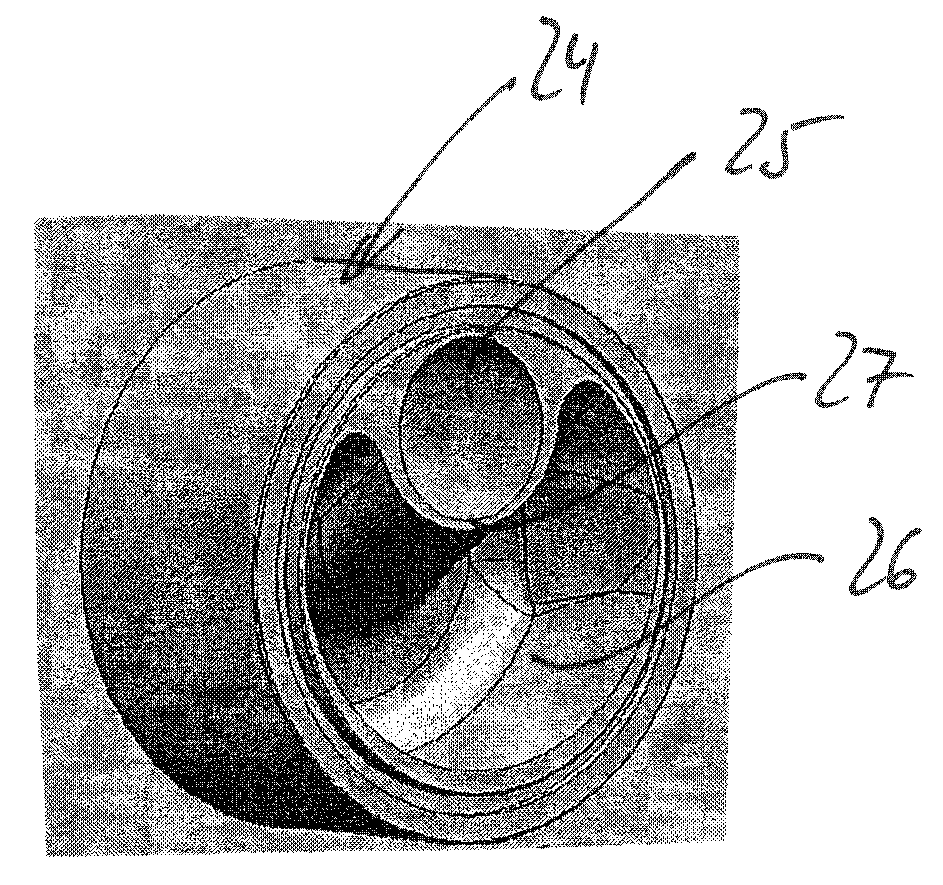

[0033] The device shown in the drawing serves to collect and guide free particles that are produced during the transport of filters containing charcoal particles from the sending point to the receiving point. However, the invention is not limited to collecting and directing free charcoal particles while transporting filters. Rather, the device is also constructed and arranged in order to collect and guide all other free particles, such as shredded tobacco, which are produced during the transport of rod-shaped products of the tobacco processing industry from the sending point to the receiving point, or which are detached from the rod-shaped products. , filter tow or other additives, such as especially wrapped and unwrapped filter rods, tobacco rods, tobacco filters and the like.

[0034] The device 10 described below and shown in the accompanying drawings is constructed and arranged for collecting and guiding free, rod-shaped, containing Particles produced during the tobacco p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com