Liquid feeding-out device with buffering type limiting pipeline road section and sliding conical bearing

A tapered bearing, liquid technology, used in non-displacement pumps, machines/engines, chemical instruments and methods, etc., can solve problems such as no regular manual maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

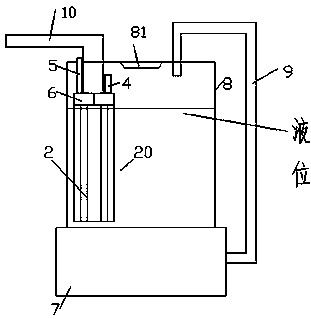

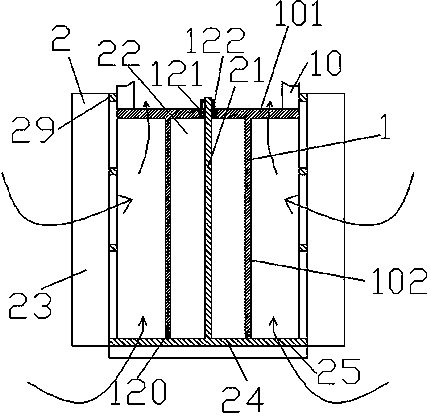

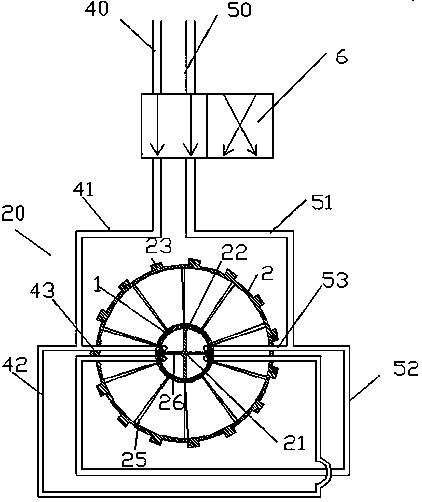

[0020] Attached below Figure 1-5 , The present invention will be described in detail.

[0021] A device for supplying liquid by air pressure with a buffer type limit pipeline section and a sliding conical bearing, including a compressed air supply device 7, a pressure chamber 8, a pressure supply pipe 9, a liquid supply pipe 10, and a suction filter device 20. Wherein, the compressed air supply device 7 is used to provide pressure to the pressure chamber 8 through the pressure supply pipe 9, and the pressure chamber 8 can pressurize the liquid in the pressure chamber 8 and supply the pipe through the liquid 10 is sent out, the suction filter device 20 is arranged at the inner end of the liquid supply pipe 10, and is used to filter the liquid when the liquid supply pipe 10 draws liquid from the pressure chamber 8; the liquid supply pipe 10 The outer end of is used to flow out liquid; the top of the pressure chamber 8 is provided with a liquid inlet 81.

[0022] The suction filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com