Switching position prompting method for multi-filtering-liner backwashing switcher of water purifier

A technology for switching positions and waterway switches, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve problems affecting the popularization of water purifiers, and achieve the effects of cost saving, high-grade products, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. The cover and the base are connected as a whole through a standard part or a threaded structure, and the gap between the two is sealed with a seal to form a closed inner cavity, and the seal acting between the base and the waterway switch is separated into a closed large cavity. , small cavity, and connected to the base inlet and outlet pipelines respectively. The fixed plate is limited by the limit device and the base and the cover and can only move axially. The rotating disk and the fixed disk correspondingly contact and cooperate with the rotation of the rotating shaft body to form a sealed and rotating switching interface.

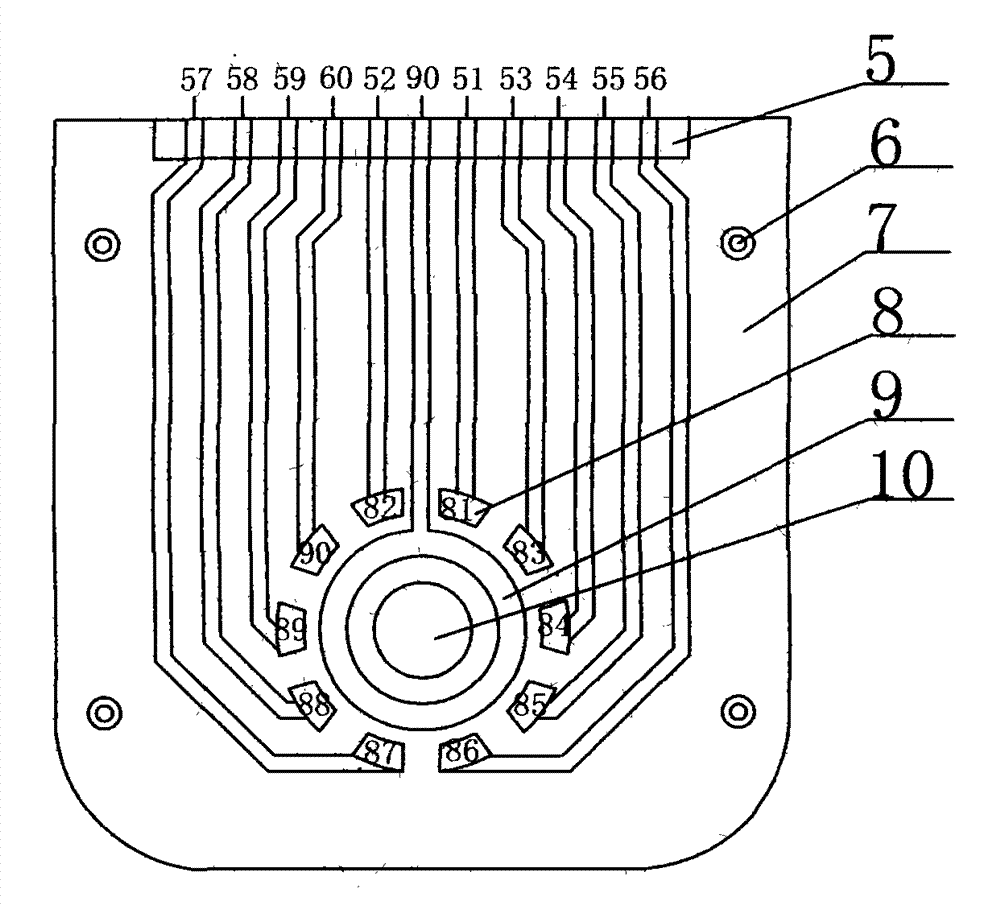

[0035] A group of ring-shaped equally divided switch contacts and ring contacts are arranged around the rotating shaft outside the base, and a transition contact is arranged on the lower end surface of the top knob of the rotating shaft. The transition contact drives the rotating disc to rotate with the rotating shaft body, conducts...

Embodiment 2

[0044] Example 2. On the basis of Embodiment 1, under the premise of not changing the structure and switching connection relationship between the elastic transition contact of the switching position prompting device and the ring contact on the circuit board and the ring-shaped equally divided switching contact 8, the waterway switch Change the switching mode of "Connection with the same disk, closed-loop switching" to Figure 5-6 The switching mode of "different disk connection, closed-loop switching" shown can also detect and prompt each switching position of the waterway switcher.

[0045] The elastic transition contact on the corresponding knob conducts the annular contact 9 on the circuit board and the contact 81 on the annular bisection switching contact 8, and the switching position prompting device prompts that the waterway switcher is in the "filtering" position, and the tap water passes through the machine Seat water inlet pipeline, closed inner cavity, waterway swit...

Embodiment 3

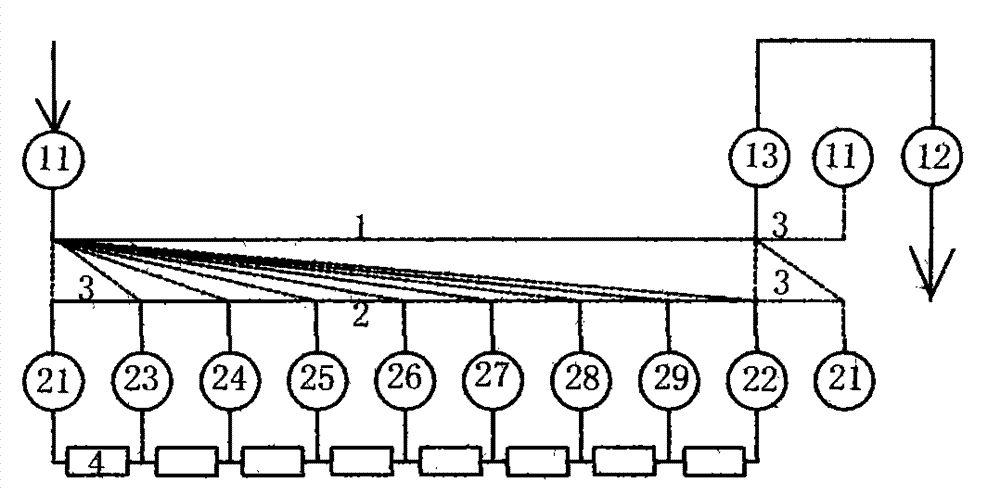

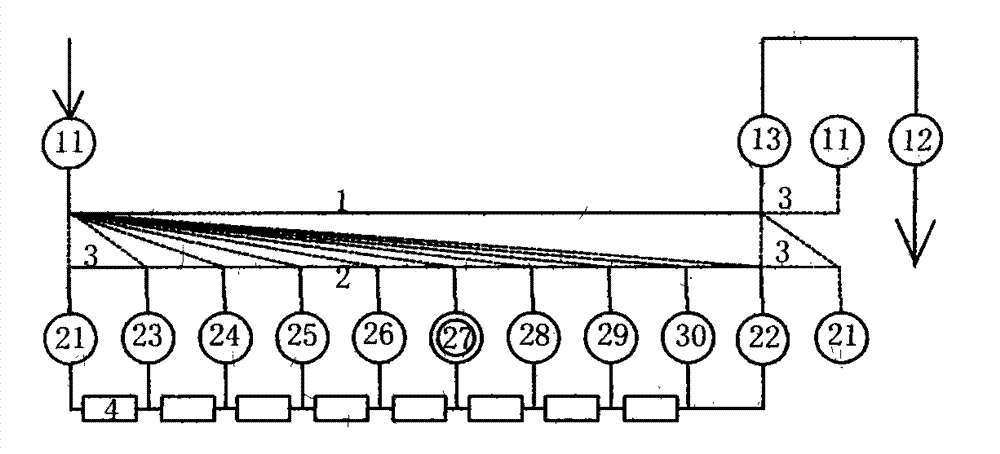

[0048] Example 3. figure 1 and Figure 7 The combination shows the technical solutions of the present invention for open-loop switching, closed-loop pipeline connection, and switching position prompting. During the rotation of the rotating disk 1, the water inlet bend hole 11 and the switching blind hole 13 on the rotating disk 1 respectively correspond to two sets of fixed disk 2 switching nozzles to switch to form an open-loop switching mode: the water inlet bending hole 11 on the rotating disk 1 is in turn When docking with the switching nozzles 21, 23, 24, 25, 26, 27, 28, 29, 22 of the fixed plate respectively, the switching blind hole 13 is correspondingly connected with the switching nozzles 30, 31, 32, 33, 34, 35, 36, 37. Wherein, the fixed plate switching nozzles 21, 23, 24, 25, 26, 27, 28, 29, 22 are the first group of filter switching nozzles respectively connected in the segmented pipelines between the eight series-connected filter galls; The eight switching wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com