Automatic unstacking system

An automatic and conveying system technology, which is applied in the direction of object destacking, object stacking, transportation and packaging, etc., can solve the problems of high labor intensity and unfavorable management, achieve small footprint, improve operation efficiency and reliability performance, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further explained:

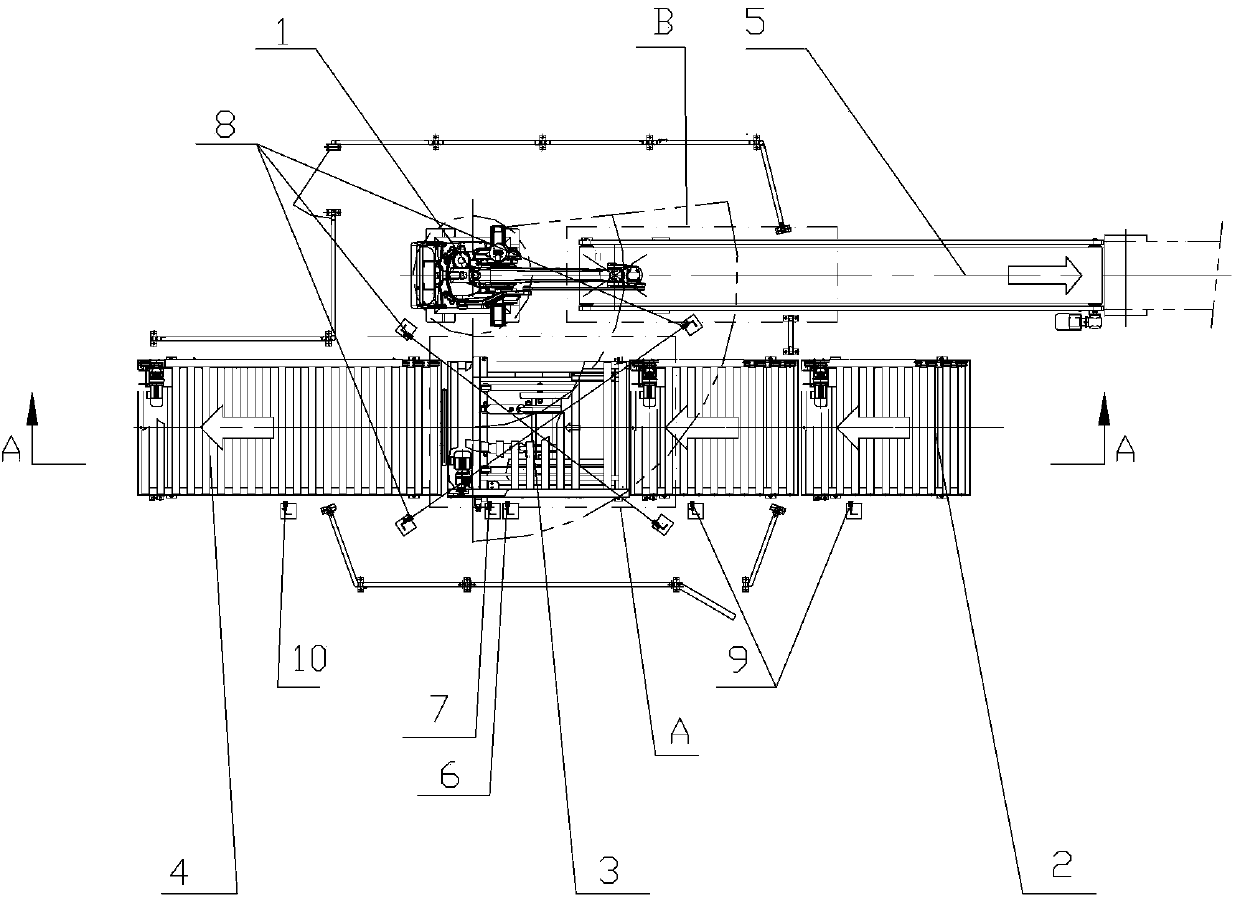

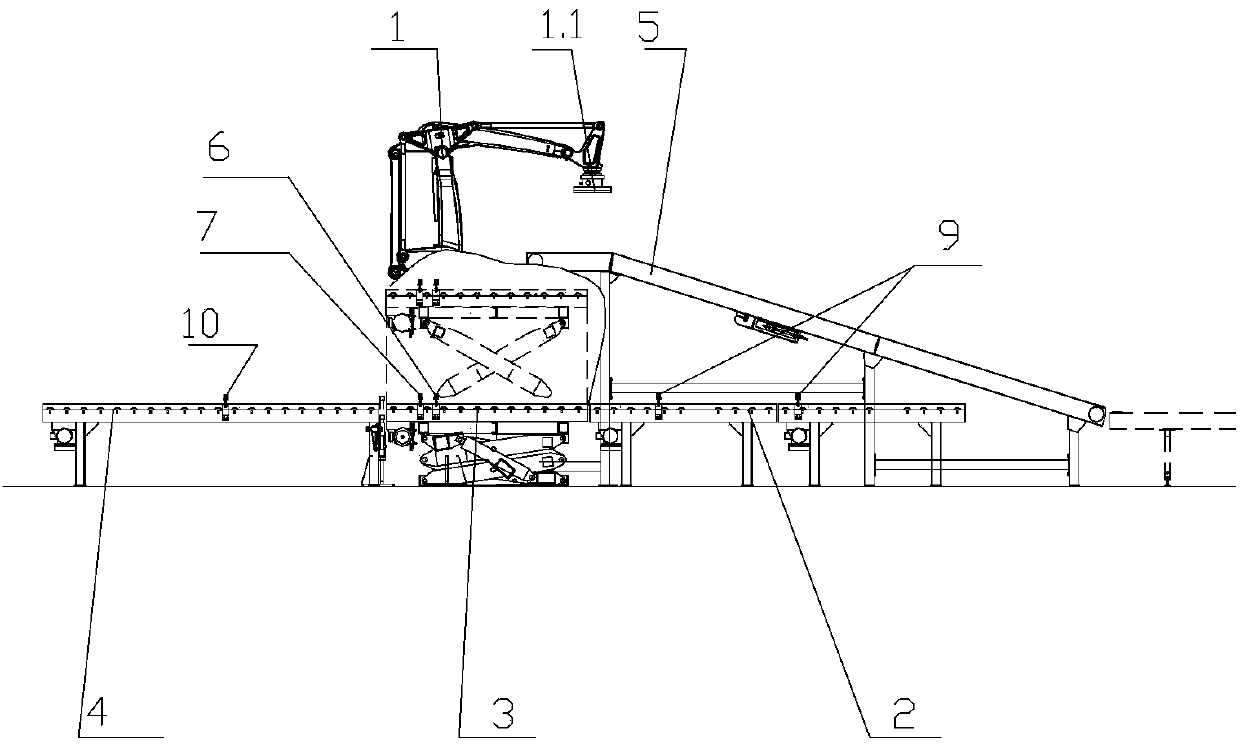

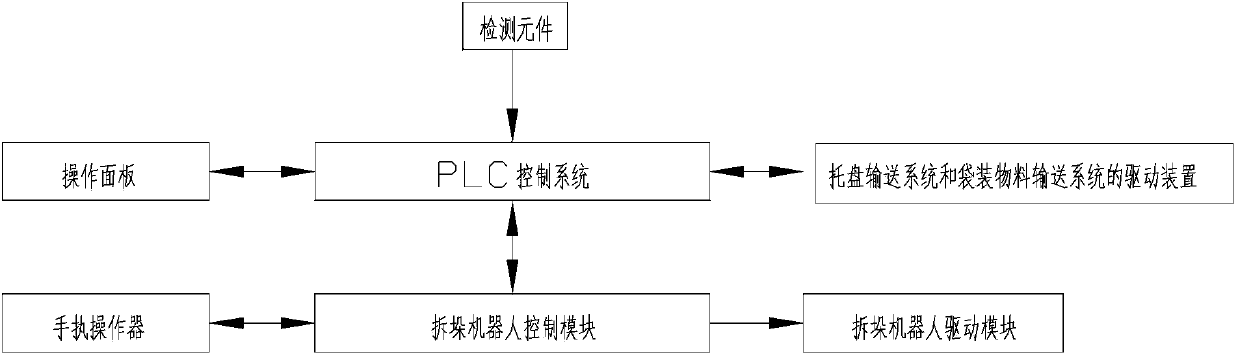

[0016] refer to figure 1 and figure 2 , the present invention includes a robot, a pallet conveying system, a bagged material conveying system, a control system and a detection element, and the pallet conveying system includes a full stack pallet conveyor 2, a lifting pallet conveyor 3 and an empty pallet conveyor 4 connected in sequence, The bagged material conveying system is a slope conveyor 5, and the robot is a destacking robot 1 equipped with a vacuum suction cup 1.1 on the wrist, and a destacking area A and a conveying area B are provided at the 1st week of the destacking robot. The pallet conveyor 3 is located in the unstacking area A, and the slope conveyor 5 is located in the conveying area B. see image 3 , the control system includes a PLC control system connected to the robot control module, and the PLC control system is also respectively connected to the o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap