A kind of purification production method of Pisicarib hydrochloride

A technology for the production of Piscicarbyl Hydrochloride and its production method, which is applied in the field of purification of Piscicarbyl Hydrochloride, which can solve the problems of potential safety hazards of purified products, and achieve the effects of being convenient for industrial production, less times of purification, and simple in the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1. the purification of Pixicaride Hydrochloride

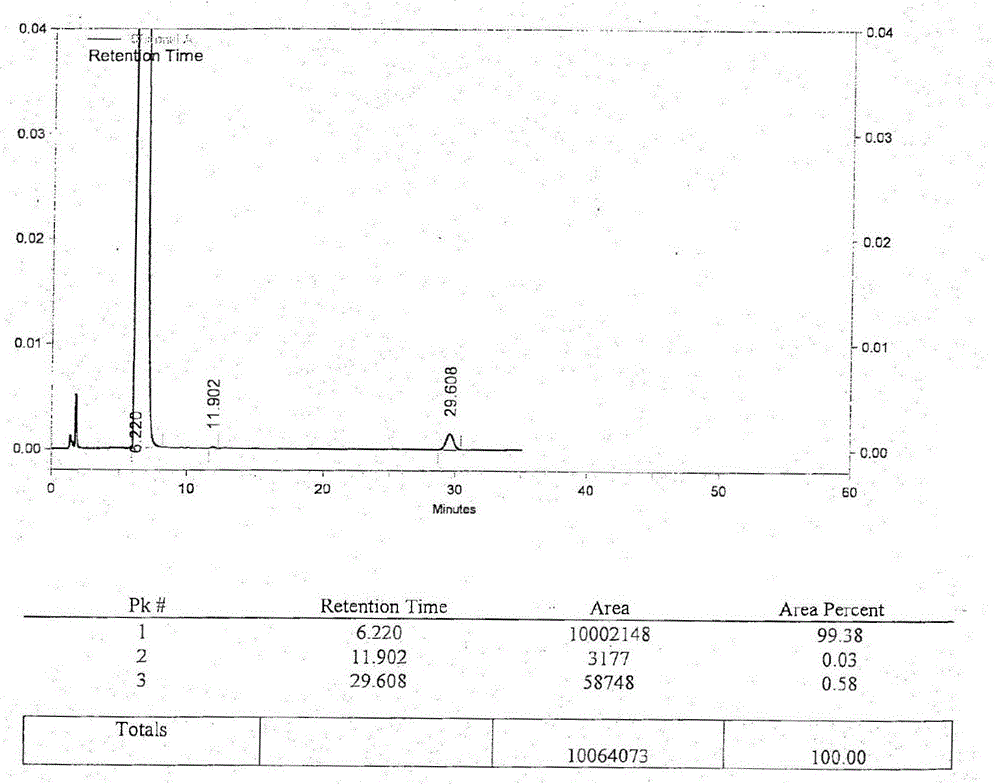

[0038] In a 250ml three-necked flask, add 53g of crude product of Pisicani hydrochloride (prepared according to the crude product of Pisicani hydrochloride), 160ml of N,N-dimethylformamide, stir and heat until completely dissolved, add 2.7g of activated carbon and heat to 130 After decolorizing at ℃ for 1 hour, lower the temperature to 80℃ and filter while hot to obtain the mother liquor. The mother liquor was naturally stirred and cooled to room temperature, and a large amount of off-white precipitate was precipitated. Filtered and dried to obtain a light white solid, wet weight: 48g. After natural air drying, vacuum drying at 60° C. for 10 hours gave 45 g of solid, yield: 84.9%. HPLC: 99.99%, the single largest impurity is less than 0.1%, see HPLC spectrum figure 2 .

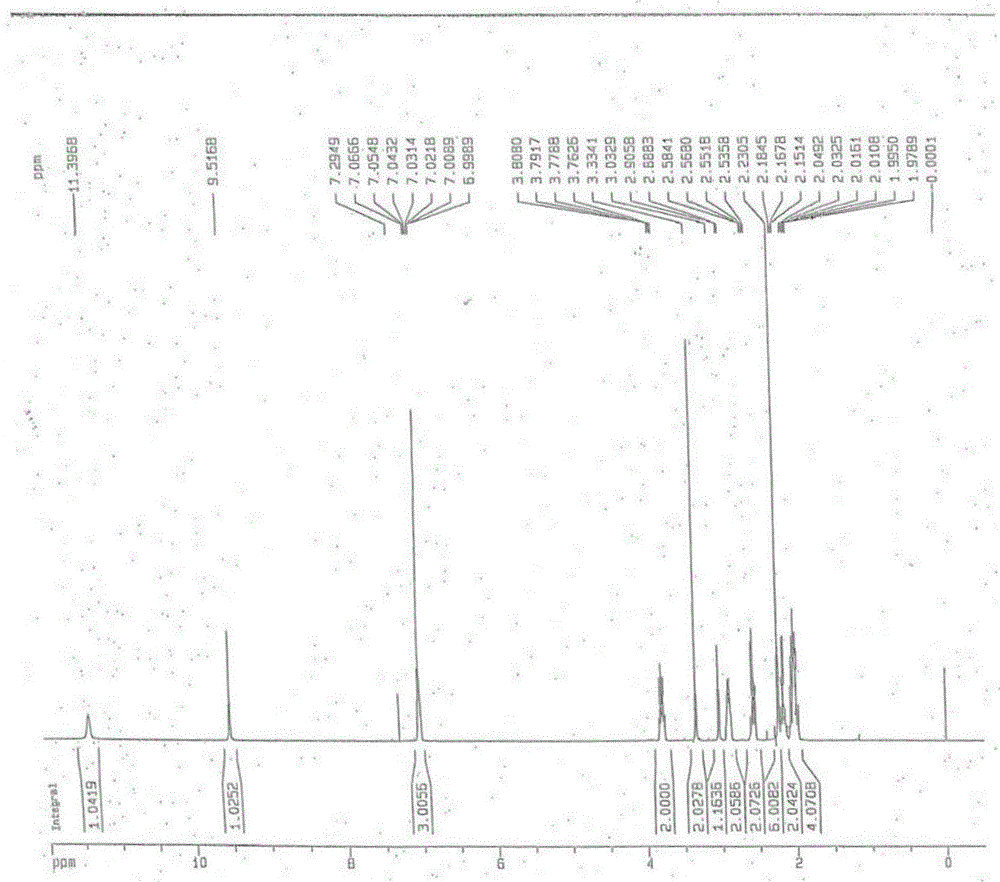

[0039] 1 H-NMR (CDCl 3 δppm) 2.014 (m, 4H), 2.168 (t, 2H), 2.23 (s, 6H), 2.56 (m, 2H), 2.89 (d, 2H), 3.03 (s, 1H), 3.33 (2, 2H) , 3.78 ...

Embodiment 2

[0040] Embodiment 2. Purification of Pisicarib Hydrochloride

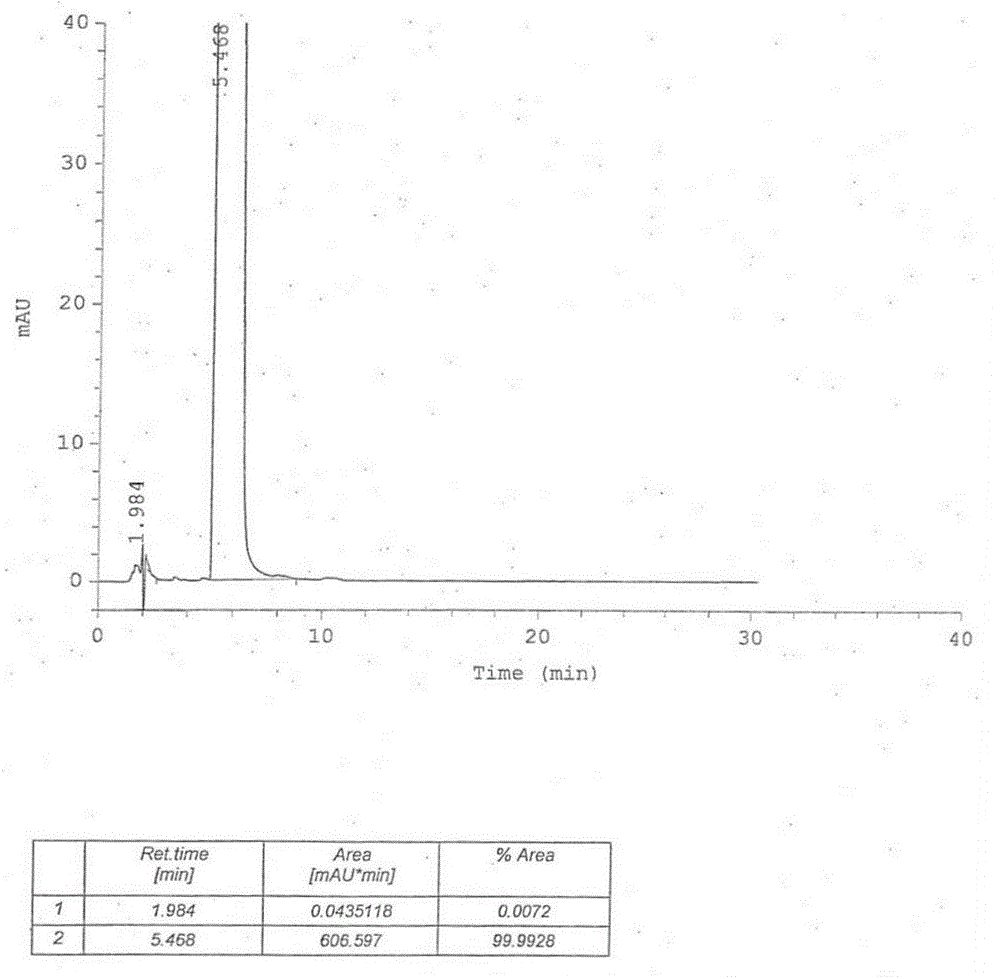

[0041] In a 250ml three-necked flask, add 53g of crude product of Piscicanide Hydrochloride (prepared according to the crude product of Piscicarnate Hydrochloride), 160ml of N,N-dimethylacetamide, stir and heat until completely dissolved, add 2.7g of activated carbon and heat to 130 After decolorizing at ℃ for 1 hour, lower the temperature to 80℃ and filter while it is hot to obtain the mother liquor. The mother liquor is naturally stirred and cooled to room temperature, and a large amount of off-white precipitate precipitates. Filter and drain to obtain a light white solid, wet weight: 47g. After natural air drying, vacuum drying at 60° C. for 10 hours gave 45.2 g of solid, yield: 85.2%. HPLC: 99.97%, the single largest impurity is less than 0.1%. See HPLC chromatogram Figure 4 .

Embodiment 3

[0042] Example 3. Purification of Pisicarib Hydrochloride

[0043]In a 250ml three-neck flask, add 53g of crude product of Piscicanide Hydrochloride (prepared according to the crude product of Piscicanide Hydrochloride), 160ml of N,N-diethylformamide, stir and heat until completely dissolved, add 2.7g of activated carbon and heat to 130 After decolorizing at ℃ for 1 hour, lower the temperature to 80℃ and filter while it is hot to obtain the mother liquor. The mother liquor is naturally stirred and cooled to room temperature, and a large amount of off-white precipitate precipitates. Filter and drain to obtain a light white solid, wet weight: 47g. After natural air drying, vacuum drying at 60° C. for 10 hours gave 40 g of solid, yield: 68.4 g%. HPLC: 99.96%, the single largest impurity is less than 0.1%. See HPLC chromatogram Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com