Method and device for adjusting micro differential pressure at converter mouth

A converter furnace mouth and adjusting device technology, applied in the metallurgical field, can solve problems such as waste of resources, large negative pressure at the furnace mouth, shortened recovery time, etc., to achieve the effect of avoiding waste and prolonging the recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

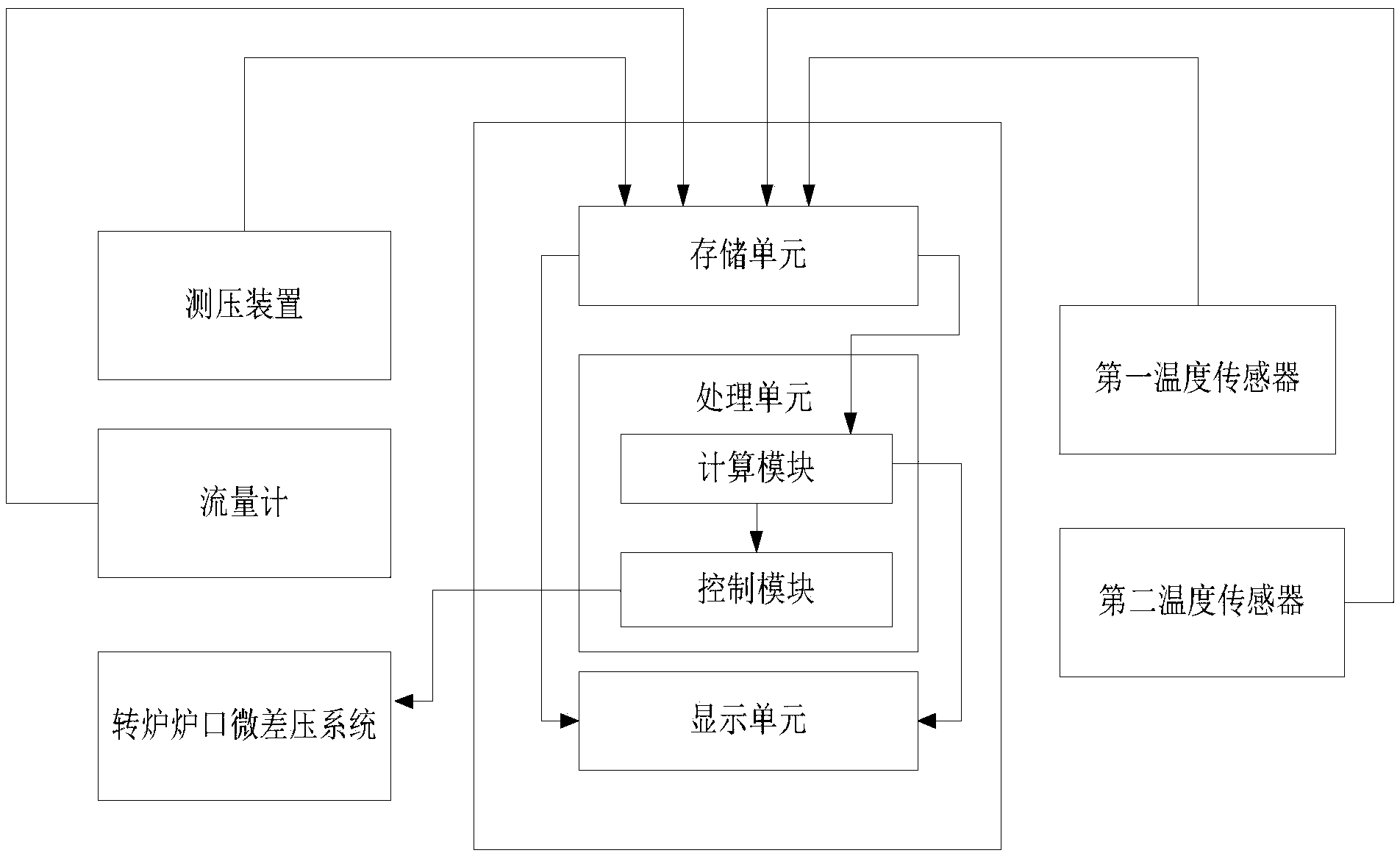

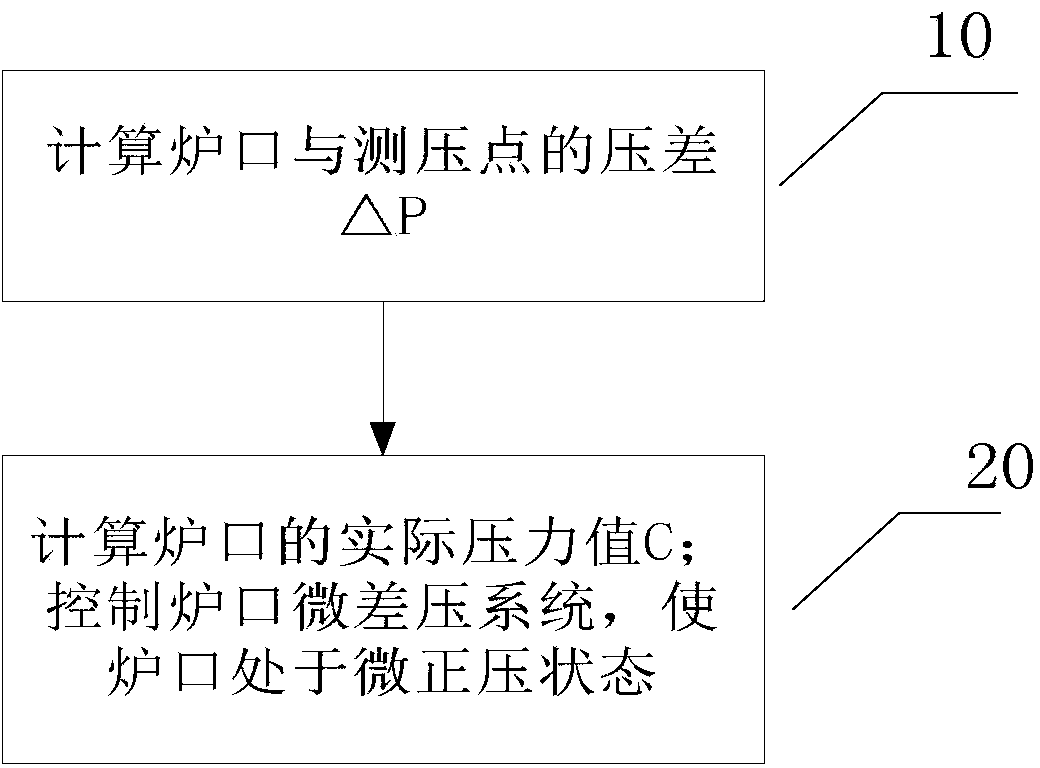

[0012] During the smelting process of the converter, the differential pressure system at the furnace mouth of the converter is responsible for monitoring the pressure of the furnace mouth at all times, and adjusting the pressure of the furnace mouth according to the monitored value to keep the furnace mouth in a slightly positive pressure state. Since the pressure point of the differential pressure system at the furnace mouth is a certain distance from the furnace mouth of the converter (the pressure measuring point is generally above the furnace mouth of the converter). Therefore, there is a certain difference between the pressure value measured at the pressure point and the actual pressure value at the converter mouth. Therefore, when setting the pressure balance adjustment value of the differential pressure system at the furnace mouth, it is necessary to consider such a difference, that is, the measured value of the pressure point of the differential pressure system at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com