Construction-member-type light retaining wallboard

A kind of enclosure wall and lightweight technology, which is applied in the direction of building components, building structures, building materials, etc., can solve the problems of heavy site workload, large material consumption, and long construction period, so as to reduce weight and save cement consumption , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

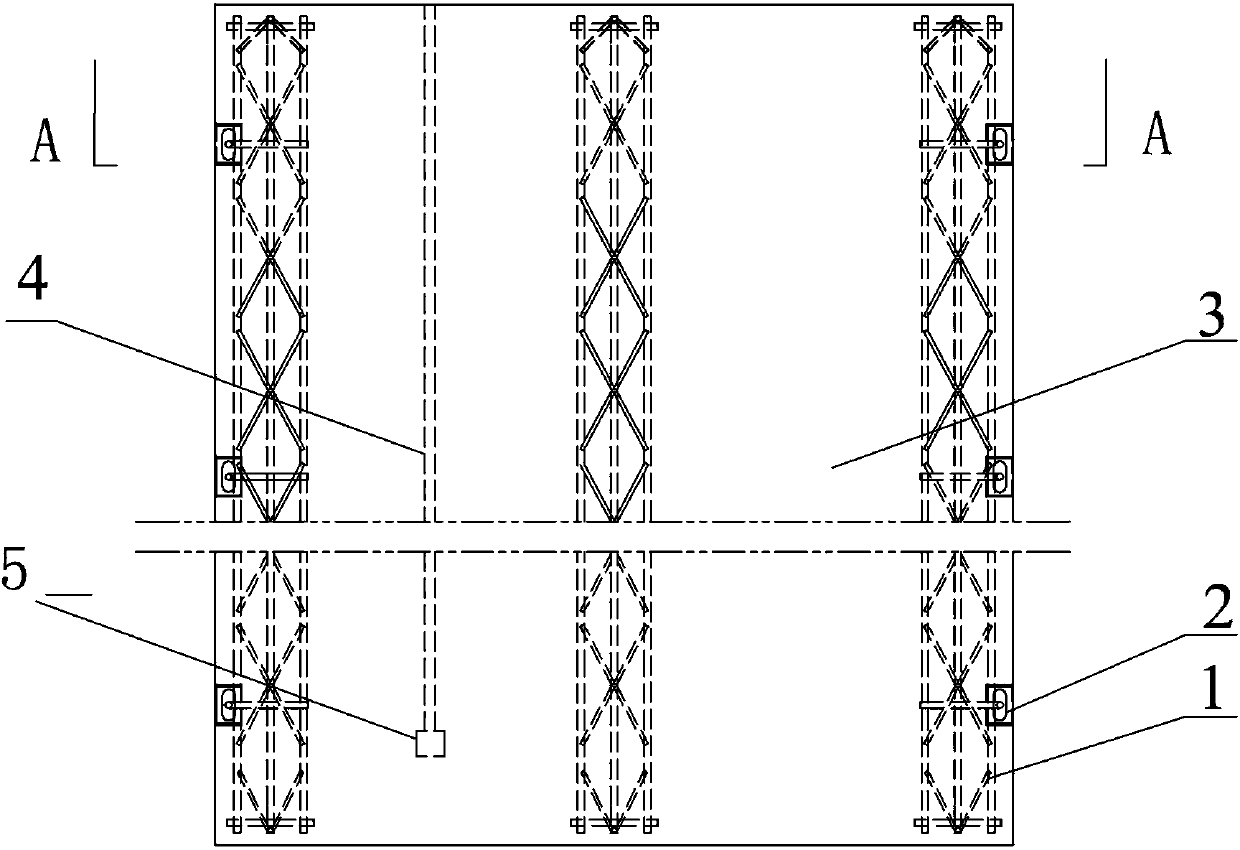

[0033] Such as figure 1 As shown, the present invention provides a novel component-type building enclosure wall panel, which is composed of a triangular truss 1, a T-shaped bolt groove 2, light cement 3, a pre-embedded electric pipeline 4, and a pre-embedded socket bottom box 5 composition.

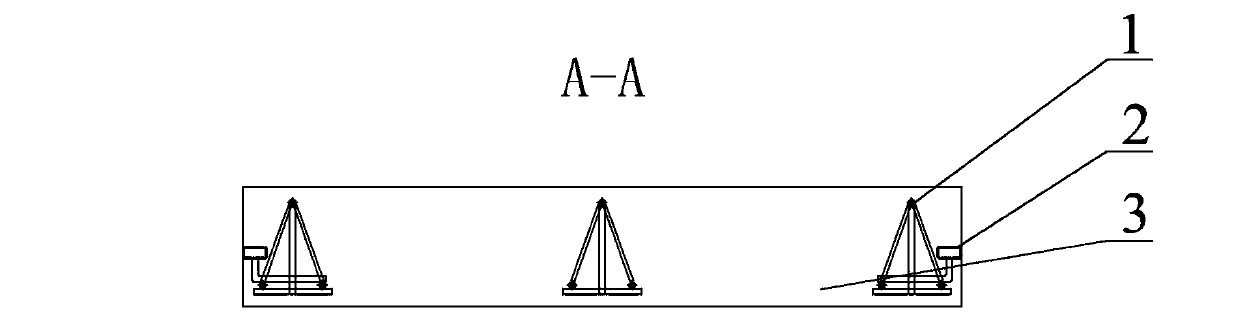

[0034] Such as figure 2 As shown, the triangular trusses 1 are evenly distributed in the light cement 3, and the truss reinforcement is left with enough protective layer thickness from the surface of the wallboard to effectively protect the durability requirements of the structural members and the requirements for effective anchoring of the stressed reinforcement.

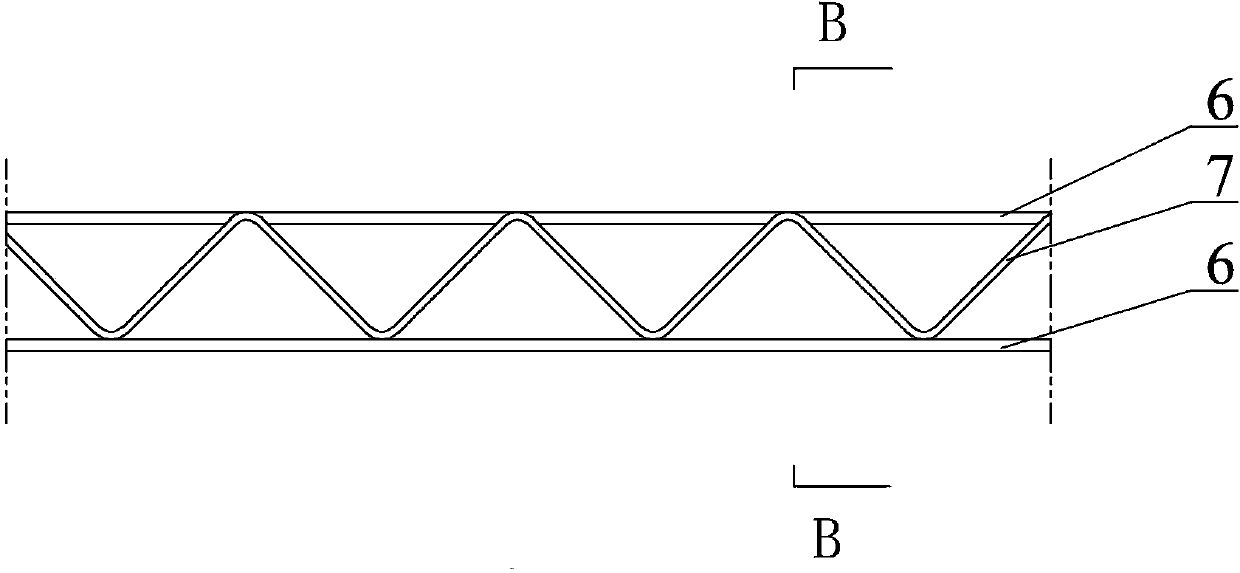

[0035] Such as image 3 with Figure 4 As shown, the main reinforcement of the triangular truss is a hot-rolled ribbed steel bar 6, and the auxiliary reinforcement is a hot-rolled smooth round steel bar 7. The auxiliary reinforcement is 70% folded and welded with the upper and lower main reinforcement in a wave shape.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com