Waterproof method and structure of large-area concrete roof silo

A large-area, concrete silo technology, applied in the direction of roof, roof covering, roof using flexible materials, etc., can solve problems such as weak waterproof ability, and achieve the effect of enhancing waterproof ability and improving protection ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The following describes the present invention in further detail with reference to the accompanying drawings and embodiments, but it is not intended as any limitation to the present invention.

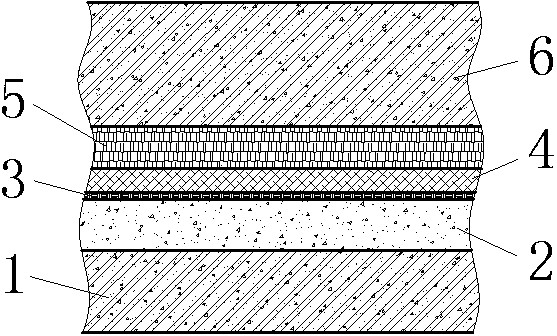

[0027] Examples. A waterproof method for large area concrete roof silos, such as figure 1 Shown. The method is constructed according to the following steps:

[0028] ① After the concrete on the roof of the concrete silo is initially set, remove the pouring formwork and rinse it with clean water;

[0029] ②. Use cement mortar to level the roof of the concrete silo. The thickness of the leveling layer is 20-25mm; the cement mortar is: ordinary Portland cement above 325 and clean medium sand with a particle size of 2.0~3.0 according to 1.2~1 : Mix evenly at the ratio of 2.5; mix with water according to the water-cement ratio 0.45-0.55 to form cement mortar.

[0030] ③ After the initial setting of the leveling layer, apply a layer of base treatment agent on the leveling layer; the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap