Manifold system for oil field and fracturing equipment group

A manifold system and oilfield technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of high cost of sand mixer, increased equipment cost, and limited increased displacement, etc. Effects of operating capacity, equipment cost reduction, and reduction in the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

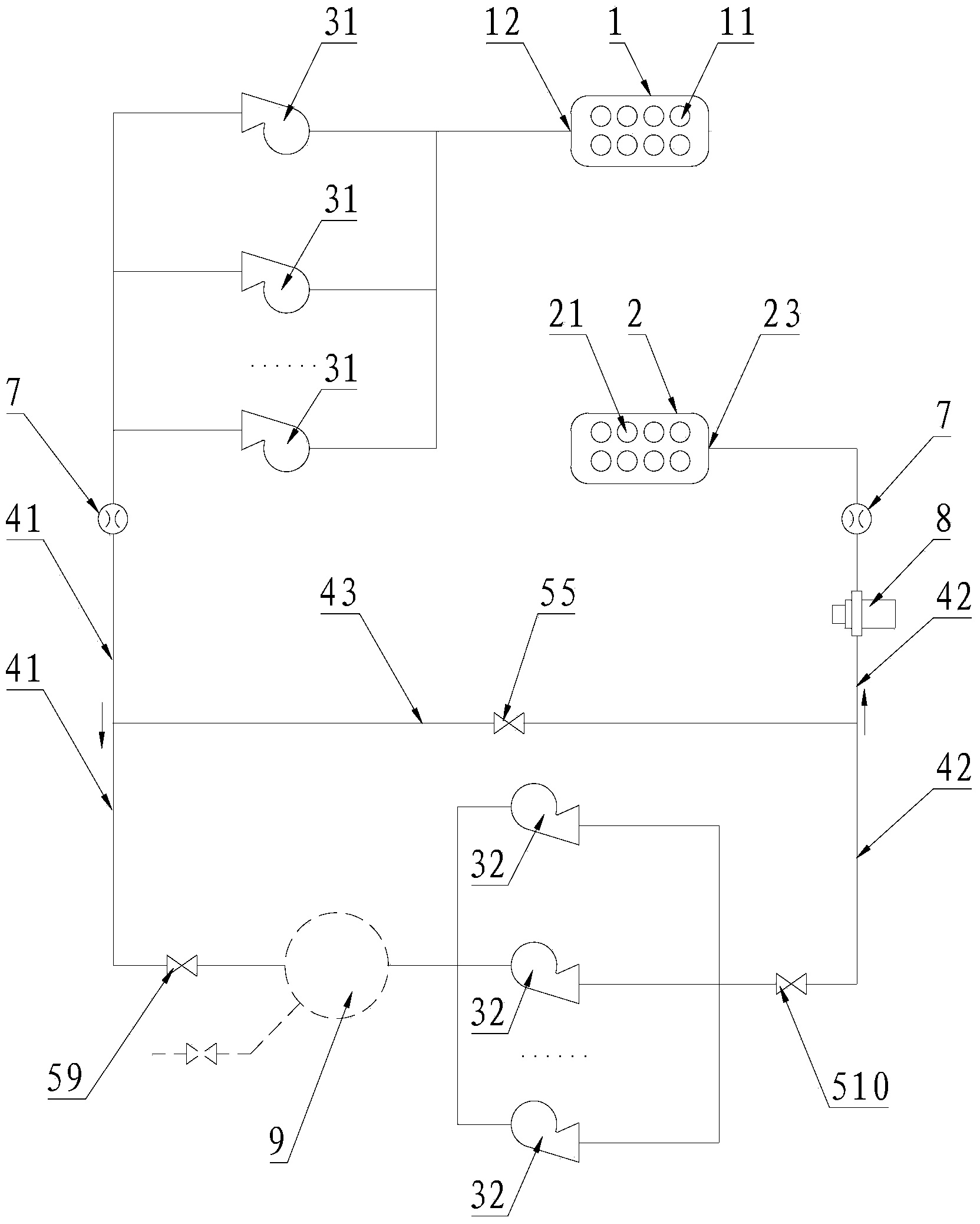

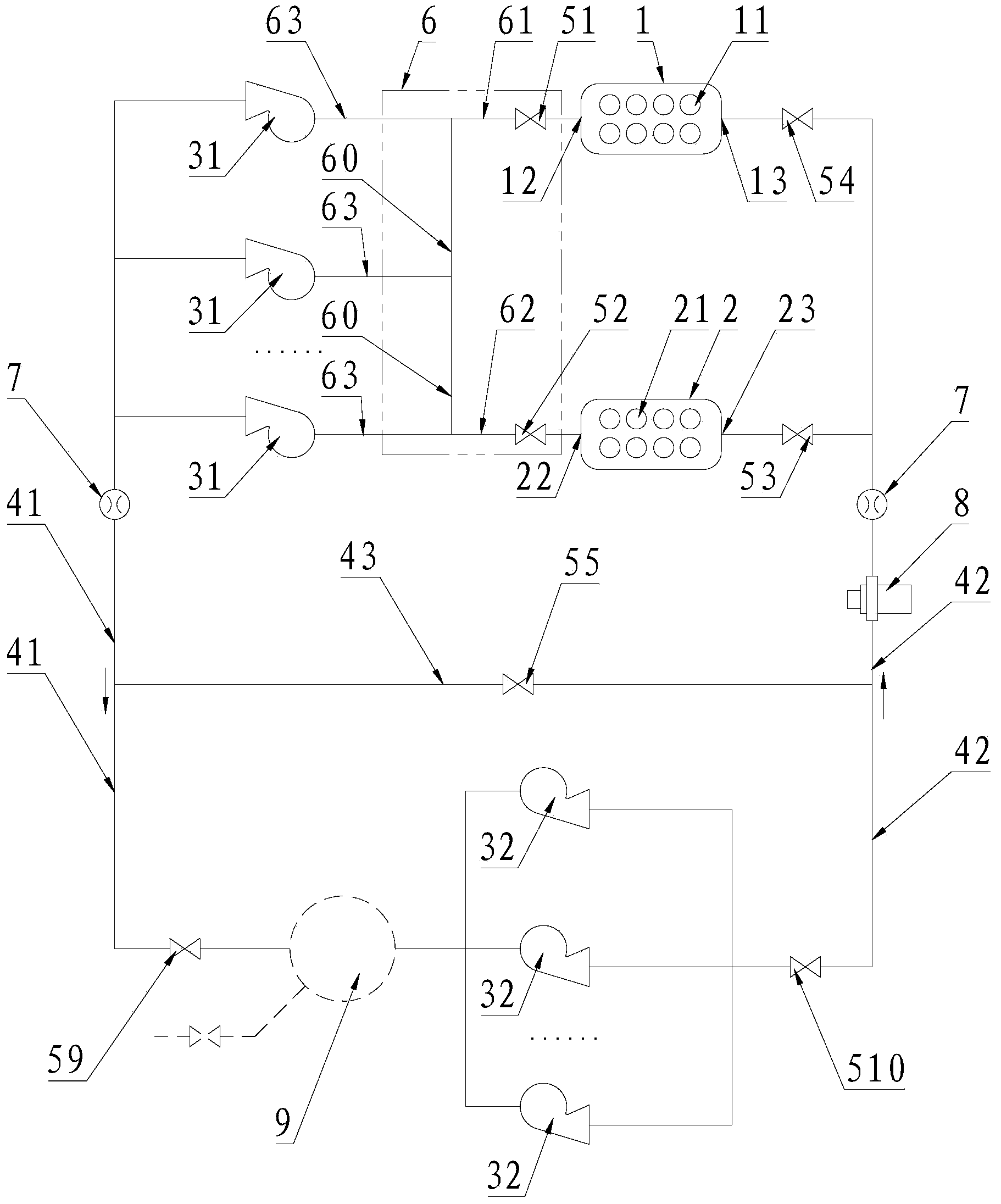

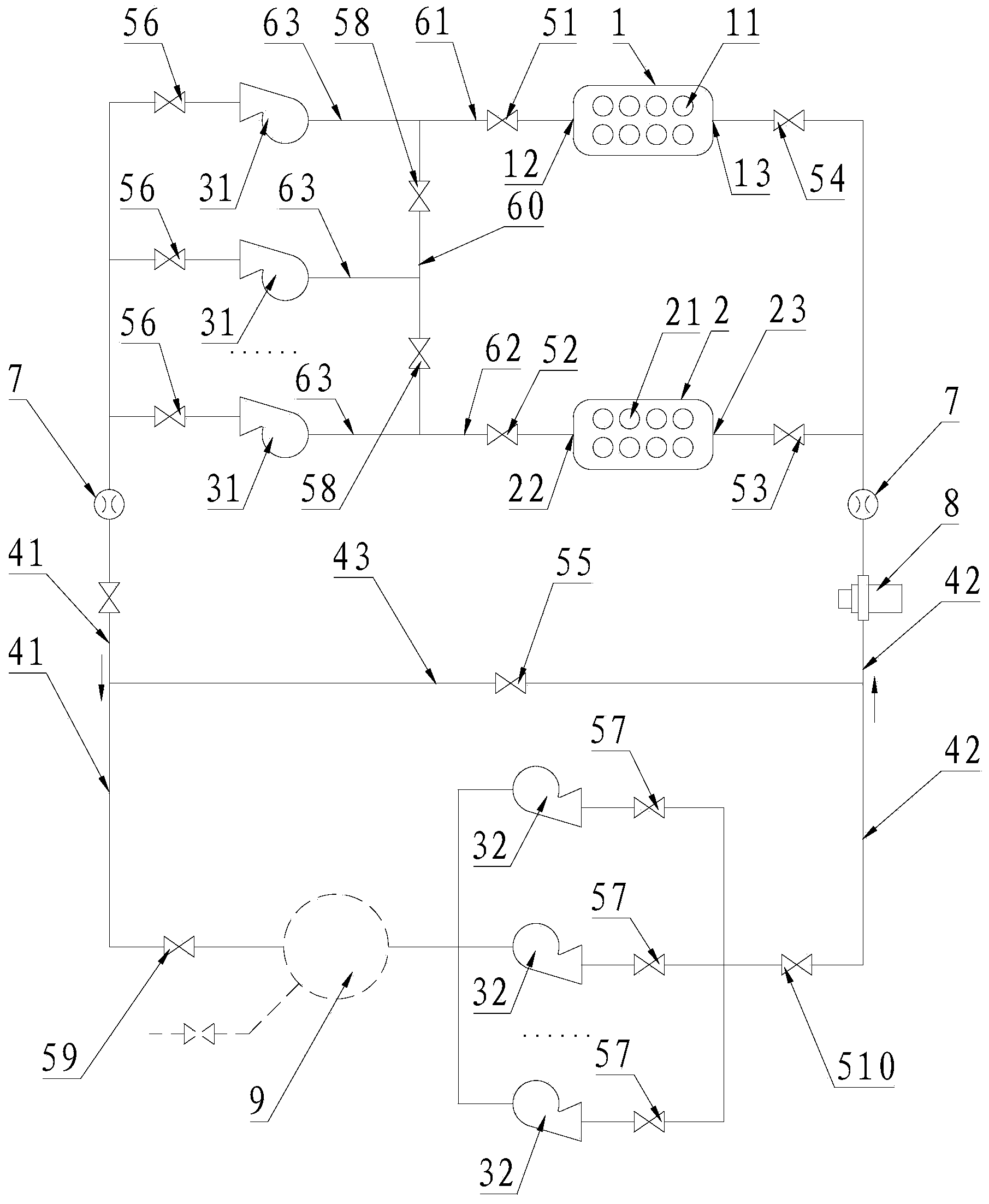

[0025] see figure 1 It shows the structural principle diagram of the oilfield manifold system provided by the first embodiment of the present invention. As shown in the figure, the oilfield manifold system (hereinafter also referred to as the manifold system) at least includes: a first pipeline terminal 1, Second line terminal 2 , at least two suction pumps 31 , suction manifold 41 , at least two discharge pumps 32 , discharge manifold 42 . figure 1 The black arrows next to the central suction main pipeline 41 and the discharge main pipeline 42 are used to indicate the liquid flow direction of the oilfield manifold system in normal operation mode. For ease of understanding, figure 1 The mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com