A kind of engine left suspension cushion assembly

A left-mounted, engine technology, applied in power units, mechanical equipment, jet propulsion devices, etc., can solve the problems of loss of durability and loss of comfort, and achieve the effects of convenient manufacturing, reduced impact and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

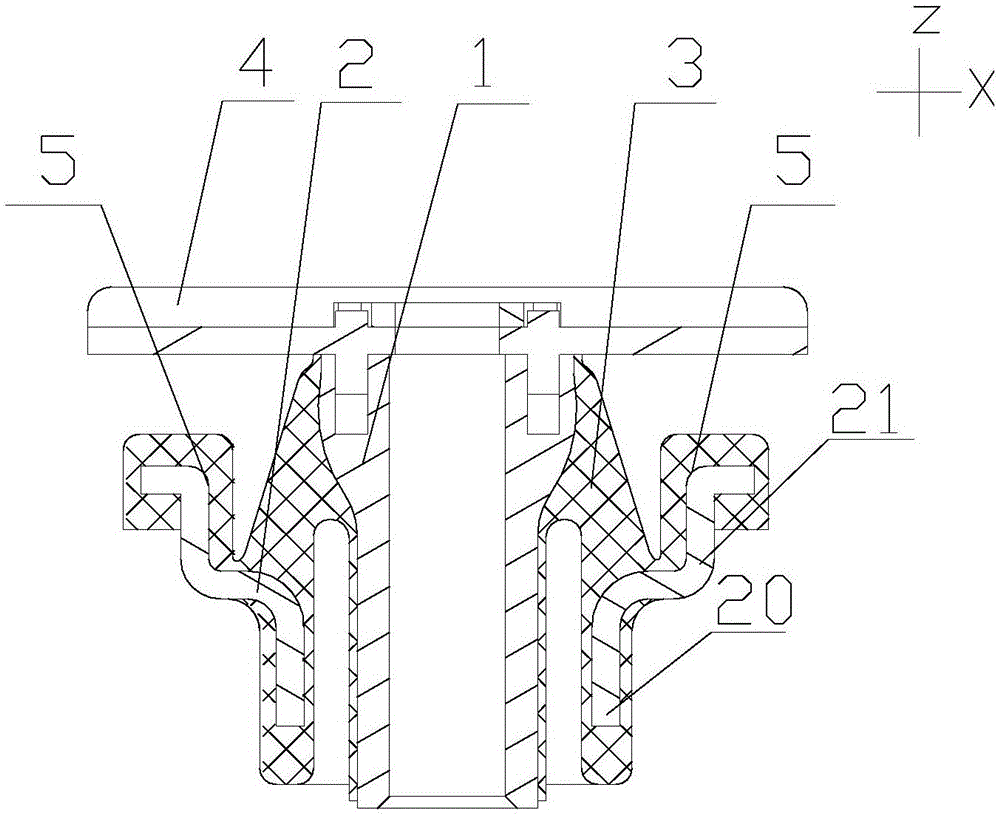

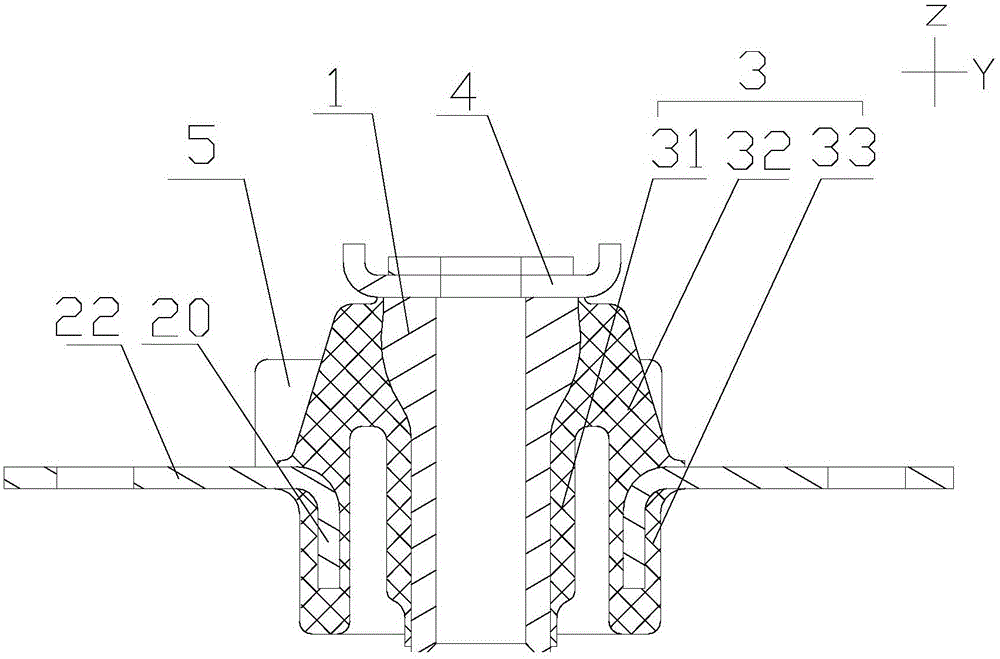

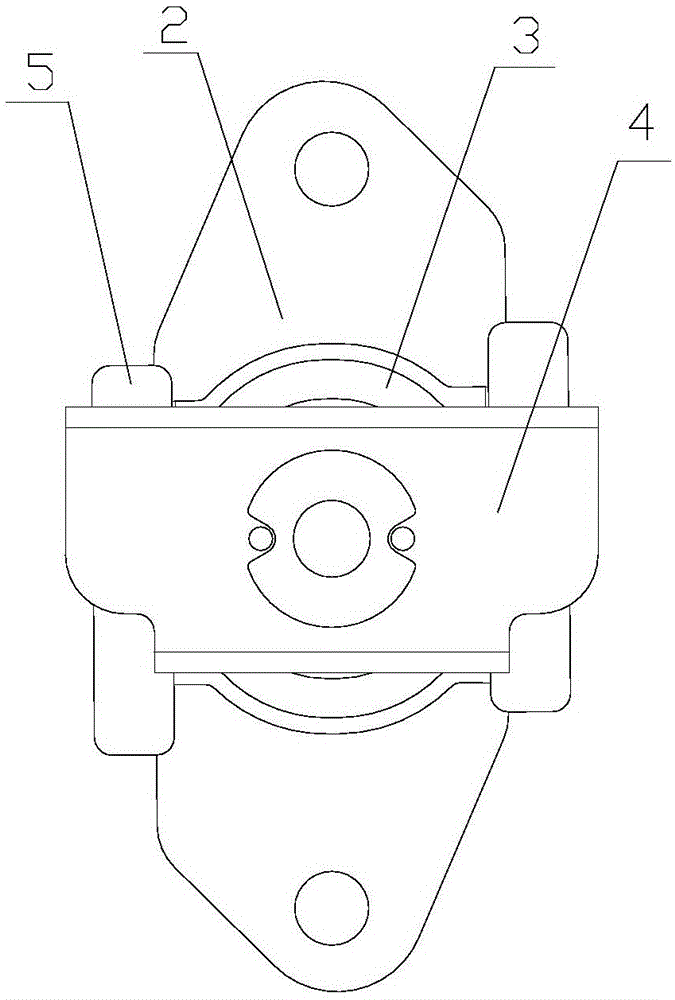

[0021] Such as Figure 1 to Figure 6 as shown, figure 1 and figure 2 Respectively, the XZ sectional view and the YZ sectional view of a kind of engine left suspension cushion assembly proposed by the present invention, image 3 and Figure 4 They are respectively a top view and a perspective view of a left engine suspension cushion assembly proposed by the present invention, Figure 5 and Figure 6 They are the three-dimensional views of the cushion and the limit bracket in the left engine suspension cushion assembly proposed by the present invention.

[0022] refer to Figure 1 to Figure 6 , the present invention proposes an engine left suspension cushion assembly, including: an inner sleeve 1, an outer frame 2, a rubber body 3, and a limit bracket 4, wherein the inner sleeve 1 is coaxially arranged inside the outer frame 2, The axial height of the inner sleeve 1 is greater than the axial height of the outer frame 2, the outer frame 2 is located in the middle of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com