A Ball Screw Pair Structure Based on Friction and Vibration Reduction

A ball screw pair, friction damping technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, feeding device, etc. Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

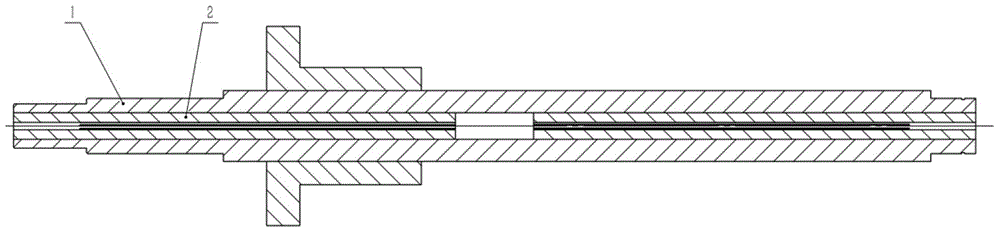

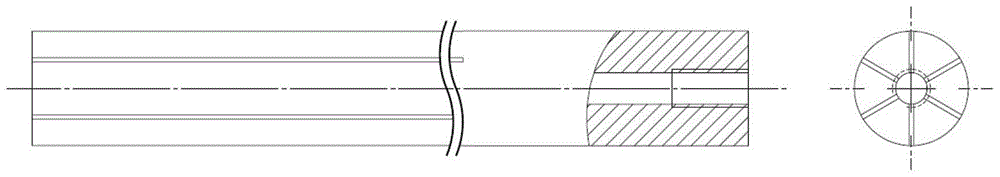

[0014] like figure 1 As shown, the vibration-damping ball screw pair structure includes a hollow ball screw pair and two friction damping rods. The finger petals of the two friction damping rods go deep into the center through hole of the ball screw, and the vibration damping rods are fixed in the hollow ball screw through the interference fit of the outer cylindrical surface. The friction damping rods see figure 2 .

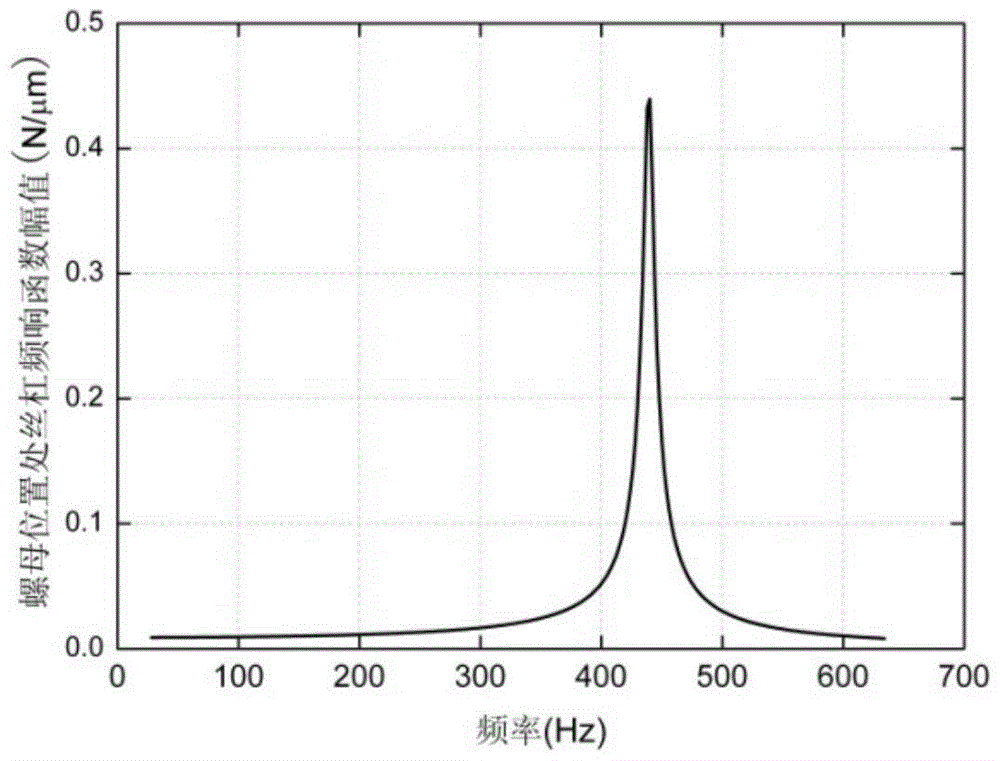

[0015] By optimizing the design of the outer circle of the finger petals of the friction damping rod and the interference of the inner hole of the screw, the number of fingers of the friction damping rod and the size of the through hole in the center of the damping rod, the moderate pressure of the finger petals of the damping rod and the inner hole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com