Electromagnetic Active Control Device for Shaft Transverse Vibration

A lateral vibration, active control technology, applied in the direction of propulsion transmission, non-rotation vibration suppression, transportation and packaging, etc., can solve the problem of no attempt to actively control the lateral vibration of the shaft system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

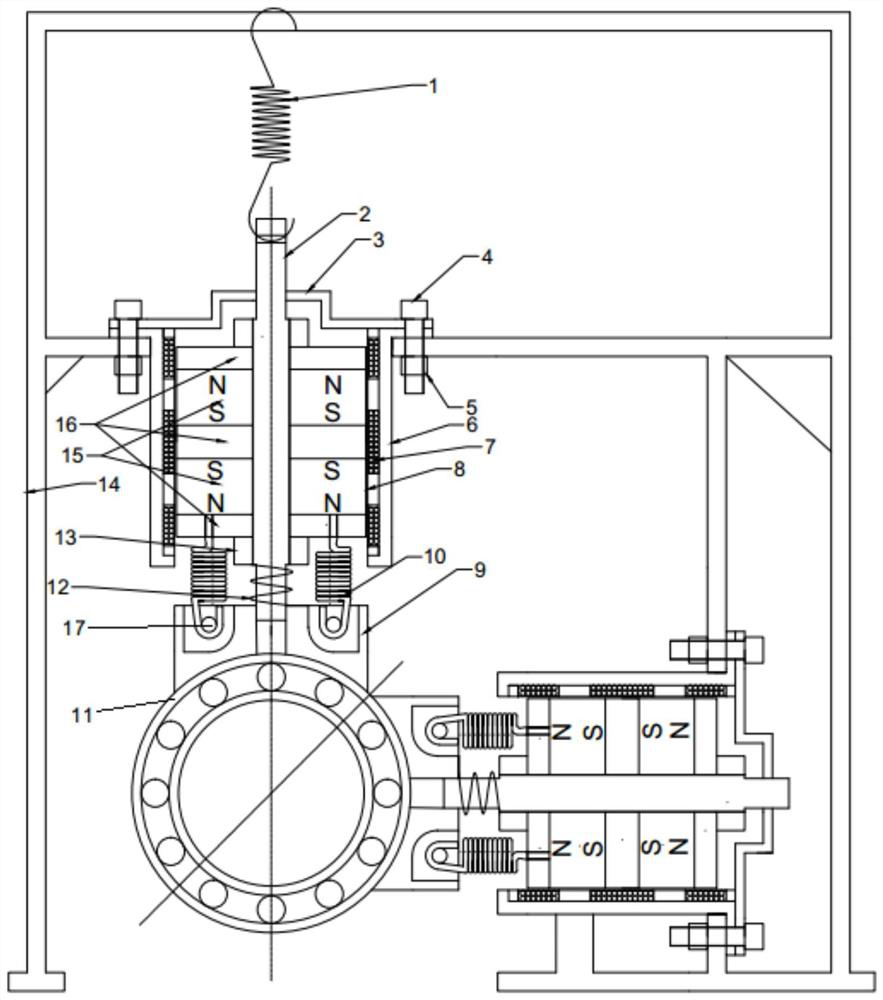

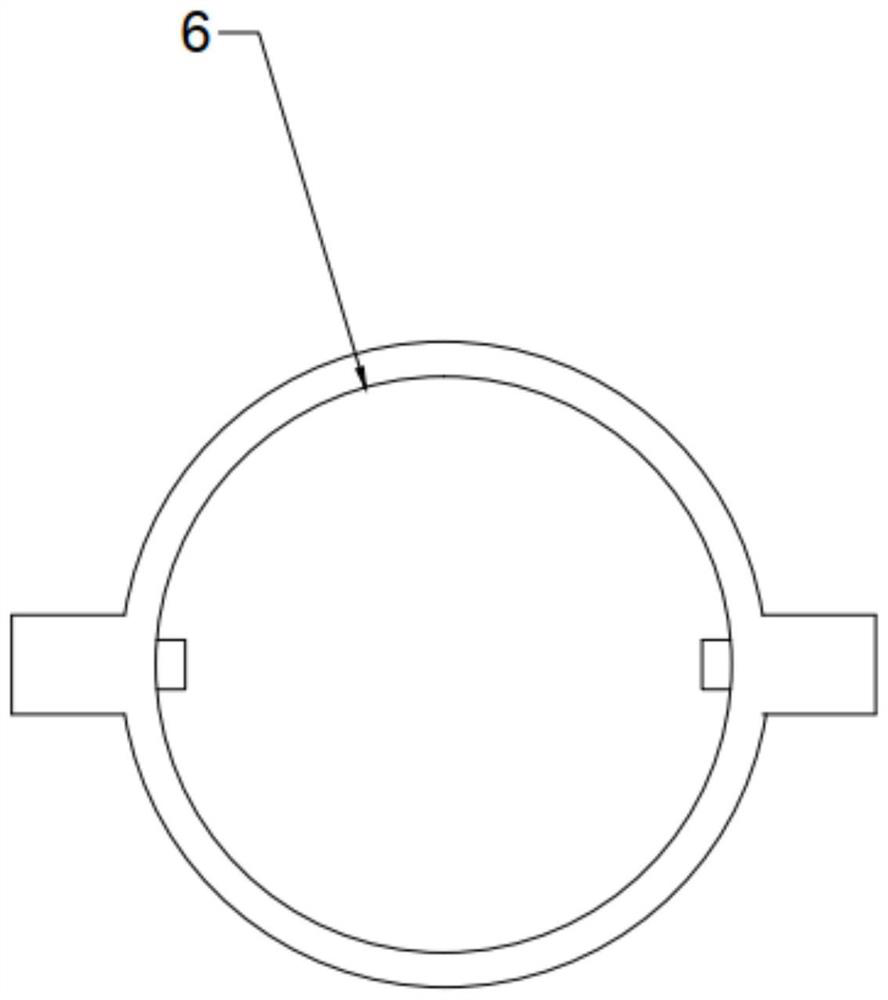

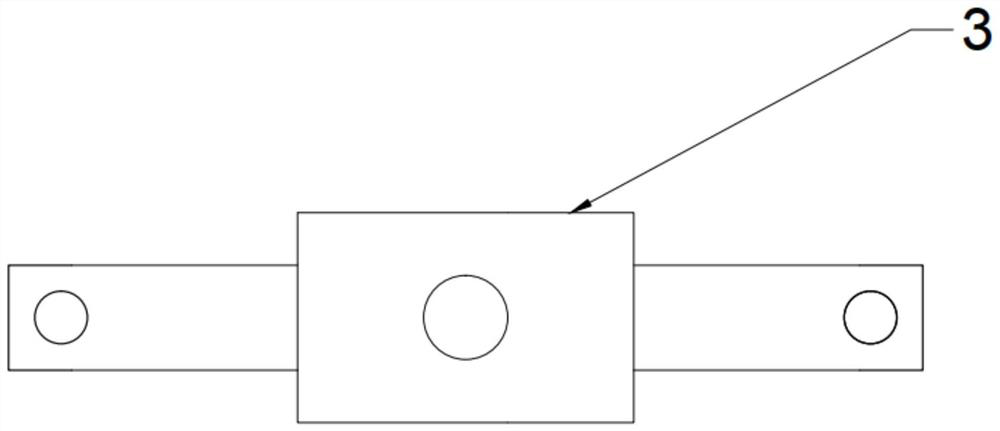

[0026] Such as Figure 1 to Figure 5 As shown, in Embodiment 1 and Embodiment 2, the electromagnetic active control device for lateral vibration of the shaft system includes a vertical unit and a horizontal unit; the vertical unit is vertically arranged, including a mover and fixed on the outer ring of the bearing in the shaft system The base 9, the mover includes a non-magnetic main rod 2 and permanent magnets 15 and magnetizers 16 fixed in the middle of the main rod 2 and arranged alternately. The upper end of the main rod 2 is connected with the balance spring 1, and the upper part is connected with the fixed guide Part 3 is sliding fit (the smoothness and material stiffness should be increased as much as possible when the sliding fit is made), the lower part is covered with a compression spring 12, and the lower end is sliding fit with the base 9 (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com