Shafting transverse vibration large force value inertia type electromagnetic active control device

A technology of lateral vibration and active control, applied in propulsion transmission, non-rotational vibration suppression, propulsion power transmission, etc., can solve the problems of small harmonic distortion, low output force value, difficult installation, etc., and achieve good linearity, Large output force, two-way force and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

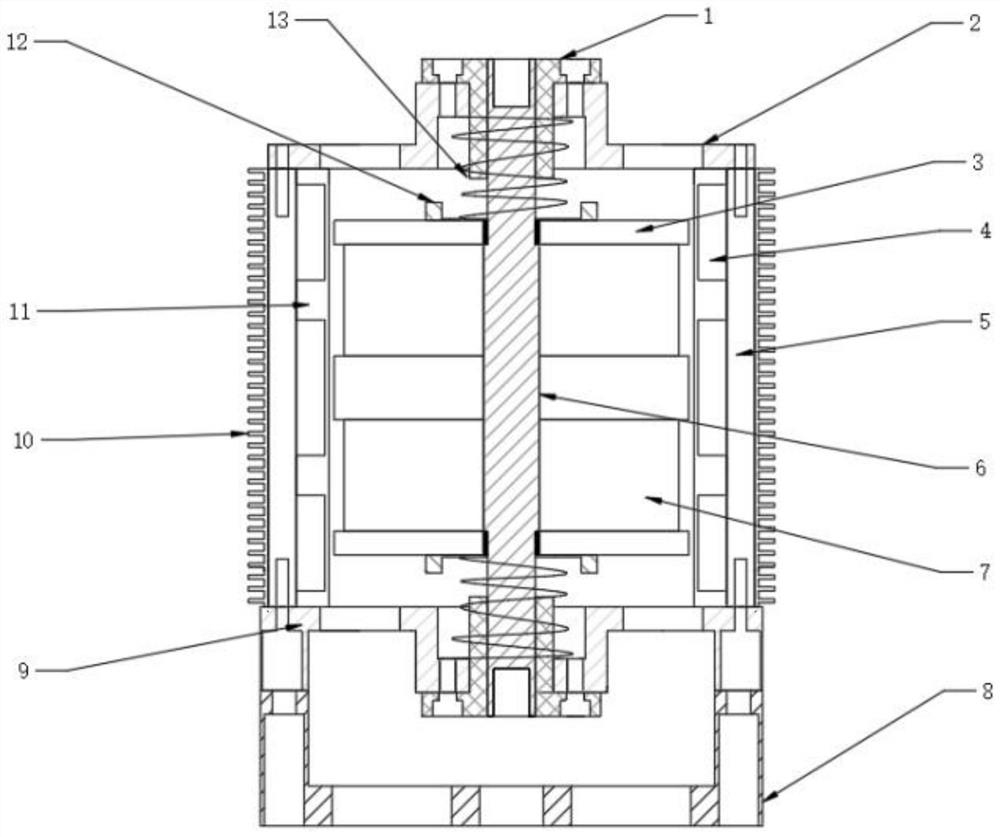

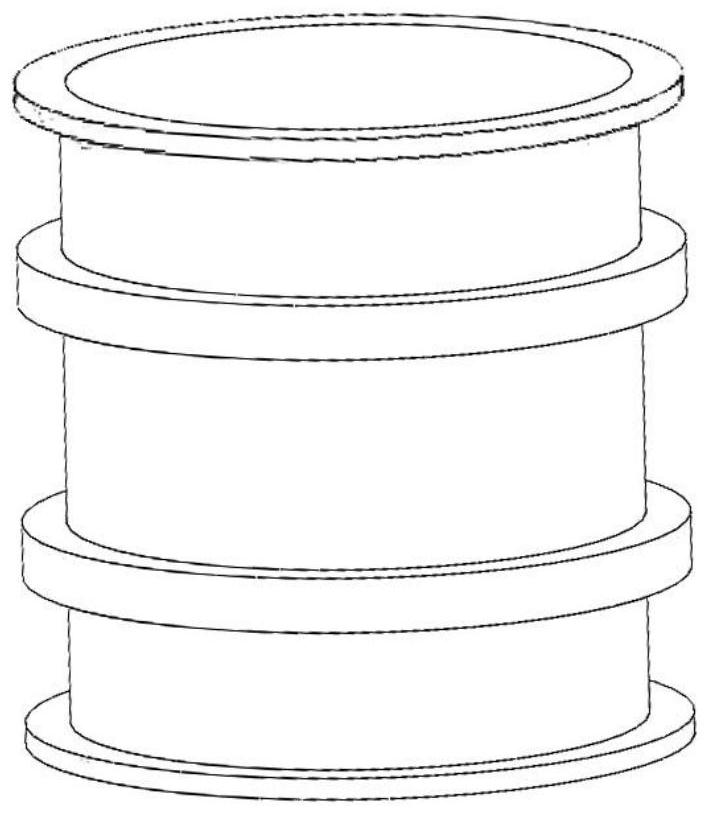

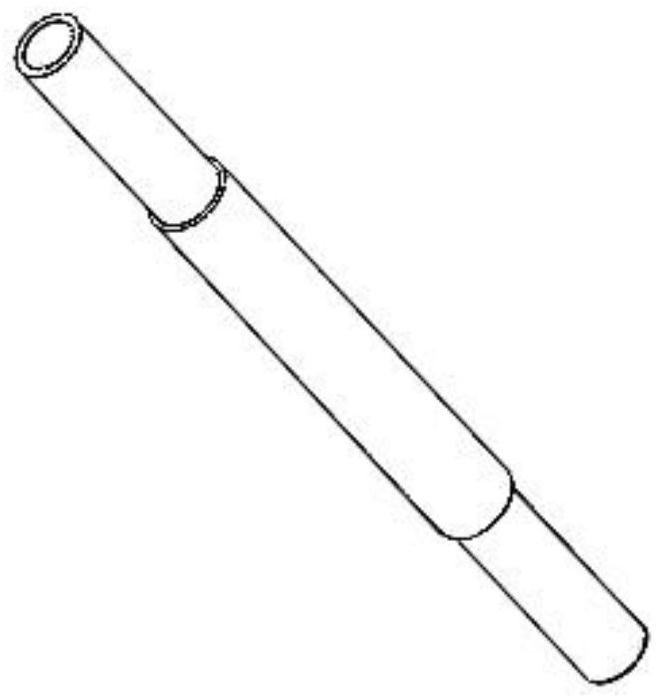

[0027] A large value inertial electromagnetic active control device for shafting lateral vibration, see Figure 1-8 , the device comprises: a magnetically conductive shell 5, an upper end cover 2 and a lower end cover 9 fixed on both ends of the magnetically conductive shell 5, a wire frame 11 arranged in the magnetically conductive shell 5, a spring radial fixing member 12, a coil 4, and a magnetically conductive body 3. The non-magnetic main rod 6, the permanent magnet 7, the compression spring 13, and the base 8 fixed on the lower end cover 9.

[0028] The non-magnetic main rod 6 is at the central axis of the magnetic shell 5, and its two ends are rotatably connected with the upper end cover 2 and the lower end cover 9 by bearings 1 fixed (as bolts) on the upper end cover 2 and the lower end cover 9 respectively. The base 8 is fixed on the outer ring of the bearing 1 and the lower end cover 9, and the base 8 and the lower end cover 9 are fixed (such as welded) to play a sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com